SEW-EURODRIVE builds learning partnerships with its DRIVEACADEMY®

Augmented reality allows trainees at the SEW-EURODRIVE DriveAcademy to learn through and interact with holographic overlays

Zander Claassens, SEW-EURODRIVE South Africa Training Manager

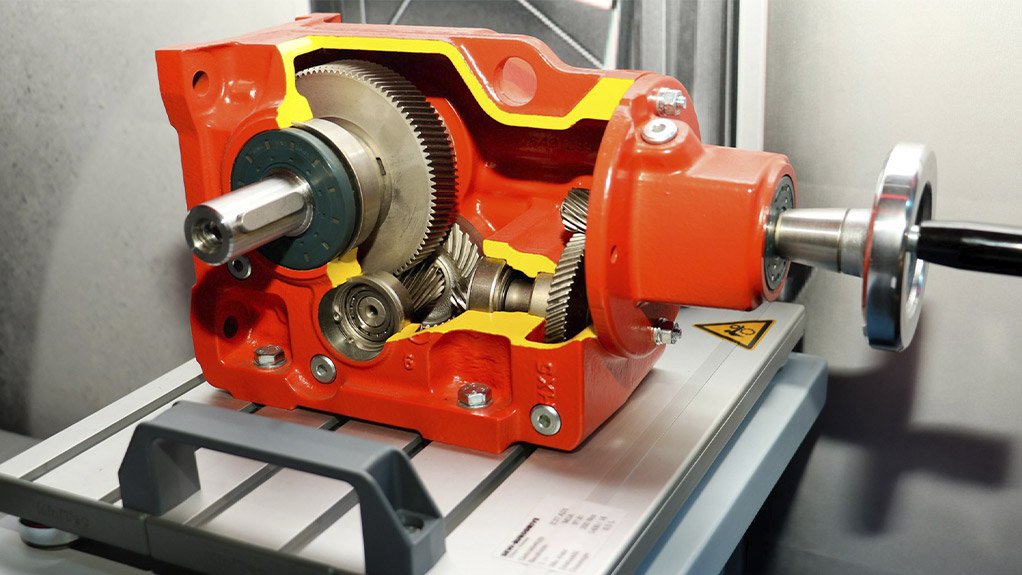

SEW-EURODRIVE’s commitment to sharing knowledge is apparent in all of the training equipment made available to trainees – from building products themselves to being able to see precisely how the product works

This article has been supplied.

With its focus on close collaboration with its customers, SEW-EURODRIVE has further raised the technological bar at its DriveAcademy® in recent years.

Committed to providing strong technical skills support behind its range of products, SEW-EURODRIVE has offered the services of its DriveAcademy® for a decade already. With the move to its new and expanded headquarters at Aeroton in Gauteng, the company has taken its learning facilities to the next level, according to Zander Claassens, Training Manager at SEW-EURODRIVE.

“Developing skills among our employees and customers has always been a high priority for SEW-EURODRIVE,” says Claassens. “The performance and reliability of our products is directly enhanced when stakeholders understand the technical details and select the right product for the application; this is a cornerstone of our successful business growth.”

In the past 18 months, there has been significant upgrading of resources in the DriveAcademy®, after the company moved into its new Industry 4.0-ready plant. These included state-of-the-art media rooms in the training wing, and the implementation of didactic products and next-generation training equipment.

Innovation is at the heart of SEW-EURODRIVE’s approach to technology, so it is unsurprising that the company takes a similar line in skills development. Keeping up with new training methods while still remaining adaptable is the only way to stay ahead of the continuous waves of change, he argues.

“We are constantly updating our training material, and also upgrading our own skills as trainers – adopting new ways of presenting,” he says. “We regularly attend international conferences in person or virtually, to discuss these innovations and share information.”

He highlights that the DriveAcademy® in South Africa is one of the first to adopt and implement augmented reality, with an eye on Industry 4.0 – allowing trainees to learn through holograms and holographic overlays.

“Not only is this a highly effective method, but is something that few people have been exposed to so it generates considerable interest and excitement among trainees,” he says. “Where trainees are exposed to memorable experiences like these, then the retention of information tends to be much greater.”

With its focus on providing solutions, SEW-EURODRIVE leverages its DriveAcademy® by applying relevant knowledge to achieve this goal. Trainees in recent years have come from various sectors including automotive, mining, refining and steel.

“We provide bespoke training for customers based on the products that they use, as well as standard product training courses with an introductory overview in drive engineering,” explains Claassens. “As with our staff, each role within a business has different requirements, so we tailor the training to suit the need.”

He notes that within the global SEW-EURODRIVE family, there are 85 drive technology centres with training departments spread across 54 countries. He emphasises that there is a strong commitment to sharing knowledge for the benefit of the global SEW-EURODRIVE brand. Ensuring high quality of deliverables, all the Drive Academies comply with the SEW-EURODRIVE international corporate standard.

“Due to the technical nature of our product portfolio, all of the training we offer is concluded with theoretical and practical tests, and competency is only declared when certain targets are met,” he explains. “Through this simple but effective process, our staff, agents and customers come to a better comprehension of their chosen topics.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation