Simulation software shortens HVAC prototyping time

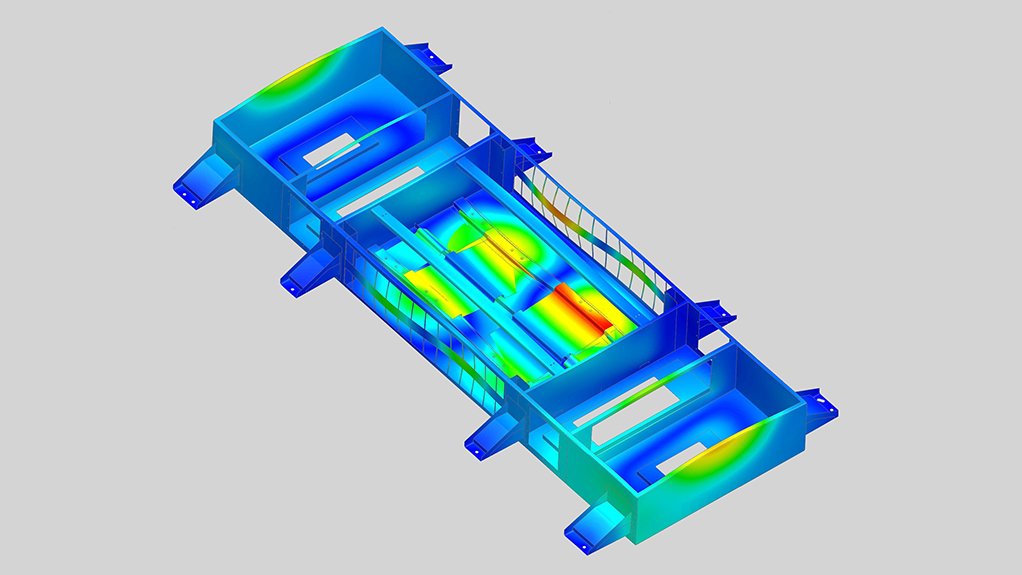

Booyco Engineering software used to determine structural vibrations within a roof-mounted HVAC system

Simulation software can help to significantly shorten product prototype development time in the heating, cooling and ventilation (HVAC) sector and Booyco Engineering says that it is using the technology to meet global standards.

“In the past, the conventional practice in product development was to build a physical prototype and then put it through a series of tests,” says Booyco Engineering MD Brenton Spies. “Often, these tests would lead to the rebuilding of new prototypes – to progressively remove the weaknesses we discovered by testing.”

The company says it has invested over R10-million in specialised Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) software, used for modelling factors such as the strength of components, structure-borne vibration, and airflow and heat distribution inside its HVACs and conditioned spaces.

“These resources allow us to run simulations and iron out most of the issues before we even build a prototype,” says Spies. “The simulations cut down significantly on the time taken by the traditional ‘trial and error’ route in developing solutions for customers, allowing us to get product to the customer faster, saving both time and money.”

Booyco Engineering says that its new capacity has led to it becoming an approved supplier to global rail original equipment manufacturers. Booyco Engineering executive director Grant Miller explains how the company became the first South African supplier to locally manufacture a cooling tower for electric locomotives and says that the value added by the software was vital to the successful outcome.

“For the cooling tower we designed and built, we physically vibration-tested the components but not the actual structure,” he says. “This was because the structure weighed about a ton and a half. But we could conduct a detailed FEA to verify the structure, which satisfied the customer’s requirements.”

The company notes that the cooling tower has successfully operated on an electric locomotive since 2016 with no structural failures.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation