Solutions to improve efficiencies in coal beneficiation

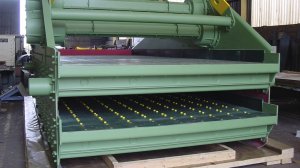

A double deck linear screen with modular polyurethane screen decks, from MBE Minerals

The use of modern vibrating screens is seen as an integral part of the drive towards improved coal beneficiation technology and increased efficiencies throughout the value chain.

MBE Minerals SA boasts a wide range of vibrating screens for sizing, scalping, dewatering and media recovery and also provides destoning solutions to customers.

“Among the company’s innovations is the side plate mounted drive, a much lighter option to using vibrator motors,” says MBE Minerals SA MD Johannes Kottmann. “The screens can also be supplied with vibrator motors if necessary, while resonance screens offer the added benefit of lower power consumption.”

All types of screening surfaces can be accommodated, with each screen incorporating mechanical design features such as vibration dampening, side plates, cross members and the appropriate feed and discharge chutes.

The company highlights that it is actively engaged with developments in coal beneficiation technology through its international network, including the MBE Coal and Minerals’ Research and Development Centre in Cologne, Germany, which consults with customers globally about optimum processing solutions and also offers customer training, which can range from general mineral processing to maintenance of MBE Minerals’ equipment.

In addition to designing, engineering and supplying equipment, the company conducts projects on a turnkey or EPC basis and can also operate complete coal processing plants. MBE Minerals is particularly well known for its BATAC jig technology, which is designed to deliver high separation efficiencies and improved product quality, as well as high availability and throughput. The technology’s ease of operation, robust design and economical maintenance cost are all seen as important factors in its success.

The company developed the BATAC jig to overcome the limitations of early stratification technologies, which achieved separation either by moving the entire jigging bed screen or through water pulsation generated in an air chamber beside the jigging bed.

“The separation accuracy of BATAC jigs is due to electronic control of the air pulse generator and sensing of the thickness and densities of the material layers being separated,” says Kottmann. The under-bed pulsated BATAC jig has proved ideal for coarse applications from 150 mm down to fine coal in the 10 mm to 0.5 mm size range, with throughput rates of between 100 t/h and 1 200 t/h.

MBE Minerals has also developed a solution for destoning raw coal, the ROMJIG, which it says has produced impressive results in extensive testing around the world. It achieves an overall reduction in the stone handled and there are indications of a lower percentage of refuse in the washery feed.

“This allows costs to be saved in a number of areas, such as reduced wear on machinery and transporting equipment, less grain degradation, and less dust and slurry,” explains Kottmann. “It also means that flocculation consumption is reduced, along with flotation agents in downstream fines recovery circuits.”

The range of vibrating screens manufactured by the company includes dimensions up to 3.6 m in width and 6.75 m in length, available in single or double deck configuration, with either circular or linear motion.

Services available include detailed engineering, feasibility studies, raw material testing, financing concepts, erection and commissioning. Components and automation and process control equipment can be supplied and installed for complete plants and systems. Measures to modernise plants or improve capacity can also be proposed. The company’s scope of services includes personnel training, as well as pre- and after-sales services and support.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation