South Africa should consider onshore LNG regasification, Fluor argues

Fluor sub-Saharan Africa GM Alejandro Escalona

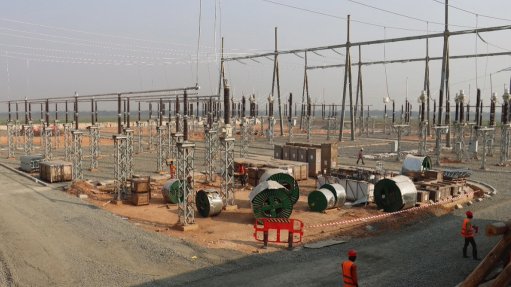

LNG jetty expansion project in Belgium

Global engineering and construction group Fluor argues that South Africa could consider both onshore and offshore storage and regasification options for the importation of liquefied natural gas (LNG), however it believes that onshore facilities could offer a number of advantages.

The South African government is currently showing a preference for a floating storage and regasification unit, or FSRU, as part of a broader plan to develop the gas importation infrastructure needed to support a gas-to-power (GTP) procurement programme.

The Department of Energy is aiming to procure 3 126 MW of gas-fired power generation from independent power producers (IPPs) and a further 600 MW from a public-private partnership involving State-owned companies.

Government’s IPP Office, which has overseen the successful renewable-energy procurement programme, is expected to release a request for proposals in the coming months for a “bundled” infrastructure and power-generation development, which could be built at the ports of Saldanha Bay, Ngqura or Richards Bay.

Fluor sub-Saharan Africa GM Alejandro Escalona, who joined the South African office in 2015 having previously led its operations in Spain, Portugal and North Africa, tells Engineering News Online that the FSRU is an understandable option. However, he believes that an onshore LNG terminal could well offer greater operational flexibility, as well as localisation potential.

He points to the experience of a number of European countries, where the decision to locate terminals onshore has made expansions easier to pursue.

“In Europe, the regasification plants started as one- or two-tank facilities with 100 000 m3 to 300 000 m3 LNG storage capacity, but have been expanded to storage capacities in the 1-million cubic metre LNG range. That ability to scale up is a big advantage that South Africa should consider.”

In addition, the localisation opportunities associated with LNG ships are limited, whereas they could be fairly significant in the case of onshore facilities. “We see the programme as a strategic opportunity and are ready to participate regardless of the model chosen,” Escalona stresses, noting that Fluor is able to participate in “everything from the ship to the grid”.

“We feel that we are in a unique position to deliver because we work in infrastructure, we have done quite a number of regasification terminals around the world, we are able to build pipelines and combined-cycle power plants and we even have a joint venture with Eskom, called Trans-Africa Projects, that does grid connection.”

DIVERSIFICATION STRATEGY

The GTP opportunity also arises as the US engineering giant moves to diversify and grow its African business portfolio to include more power- and infrastructure-related projects, having traditionally concentrated primarily on the oil and gas and mining markets in South Africa and the region.

Escalona says Fluor is also considering actively pursuing nuclear prospects in the region, with momentum gained from the appointment in 2015 of Fluor by Westinghouse Electric Company to build two AP1000 nuclear power reactors in Georgia and South Carolina, in the US. In addition, Fluor is a majority investor in NuScale Power, a small modular reactor technology company.

Besides sectoral diversification, Fluor has decided that it will also increasingly offer integrated project solutions, including construction and fabrication, rather than only selling engineering services.

In fact, the group attributes the rise in its order backlog to a record $45-billion in 2015 partly to its emphasis on its lump-sum engineering, procurement, fabrication and construction approach. In addition, the group’s recent $755-million acquisition of the 15 000-employee Stork has also increased its capacity in the delivery of maintenance, modification and asset integrity services.

Escalona says the integrated solutions model is finding favour with traditional African clients, such as Sasol and Debswana, by spanning the entire capital project life-cycle and helping to reduce costs and schedules, improve certainty of delivery and increase safety. Under the model, the company uses its five fabrication mega-yards in China, the largest in the world, Canada, Mexico, Philippines and Russia to produce ‘plug and play’ modular components for capital projects, in a bid to lower costs, compress schedule and improve project safety.

However, Escalona says the group is tailoring the fabrication solution to the strong demand in Africa for local content. “One of our current contracts in Botswana is a good example. We are doing modular construction, but instead of doing it overseas, we are helping local contractors to become modular fabricators,” he says, with the modules being built off-site, but in Botswana.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation