Technology optimises grinding operations

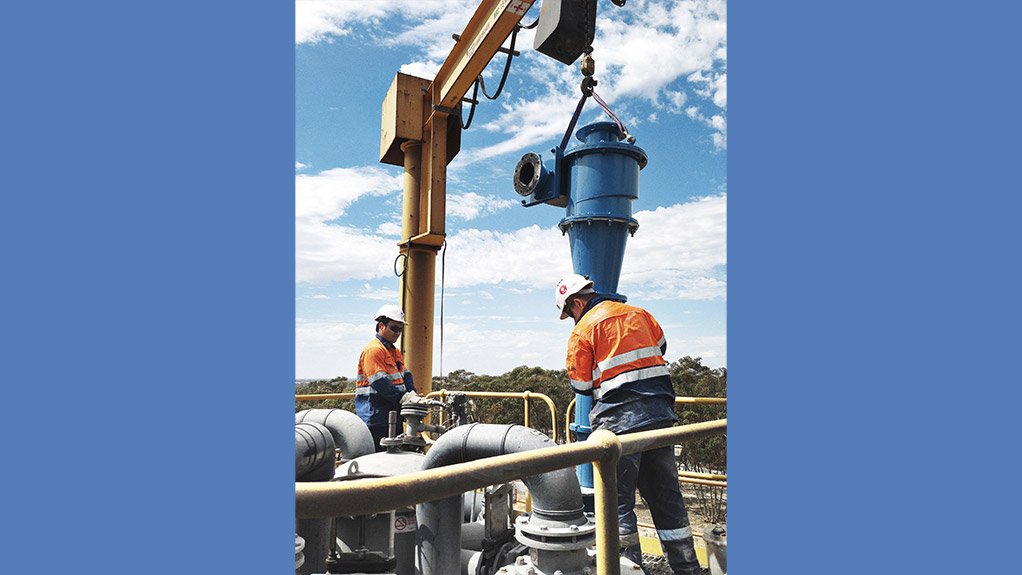

Efficient operation and minimal downtime are crucial for maintaining productivity and profitability in grinding circuits and FLSmidth says that many operations are opting for its KREBS SmartCyclone technology to address these challenges.

The company explains that the innovative technology combines advanced monitoring and automation features to optimise closed-circuit grinding operations.

“SmartCyclone integrates various components and software to provide a comprehensive solution for grinding circuit management, and significantly incorporates roping sensor technology, wear detection technology, a wireless controller system and ECS/ProcessExpert process control software,” says FLSmidth senior applications engineer responsible for KREBS pumps cyclones and valves Abrie Schutte.

The wear detection technology of SmartCyclone employs specialised sensors to monitor the wear status of cyclone components. Real-time information enables operators to plan for parts replacements and schedule maintenance activities, which helps to minimise downtime.

Schutte explains that an automated monitoring system is a key feature of SmartCyclone, allowing operators to detect wear and troubleshoot issues from a centralised control room. This eliminates the need for in-person equipment inspections with a reduction in associated risks.

Identifying and addressing potential problems helps to minimise process disruptions and optimise the performance of the grinding circuit.

The system also includes a roping detection feature, which identifies and corrects disturbances known as ‘roping’. Overloaded cyclones or those experiencing roping can lead to increased bypass of coarse solids to the overflow and greater particle size variation.

“This accumulation of slurry can adversely affect downstream equipment, such as flotation cells. By monitoring and detecting roping, operators can confidently operate the plant closer to its limits, thereby increasing production capacity and improving mineral recovery,” says Schutte.

Integrating SmartCyclone with ECS/ProcessExpert software enables the system to adjust variables such as water addition, pump speed and the number of operating cyclones based on real-time data. This continuous optimisation helps to enhance particle size distribution, maximises mineral recovery and improves the overall efficiency of the grinding circuit.

FLSmidth asserts that SmartCyclone offers a comprehensive solution for closed-circuit grinding operations. By leveraging advanced sensor technologies, automated monitoring and process control software, operators can enhance maintenance planning, reduce wear, and optimise the performance of grinding circuits.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation