The HDGASA is a lighthouse: illuminating the path with knowledge and training for galvanised steel fabrication, says associate member Rand York

This article has been supplied and will be available for a limited time only on this website.

The Hot Dip Galvanizers Association Southern Africa (the HDGASA) serves as a lighthouse, guiding stakeholders through the complexities of steel fabrication, and corrosion protection in South Africa, according to Justin Corbett, Joint CEO of Rand York Castings.

A proud HDGASA associate member and a shining example of South African export success, Rand York Castings - a family business established over 40 years ago - specialises in hot dip galvanized steel substrates and fabrications. The company supplies high-quality products to global markets in mining, civil construction, geotechnical engineering, and, more recently, agriculture.

“Today, quality is assumed, but as a nation, South Africans often lack a deeply ingrained quality ethic,” Corbett explains. Many companies aim to beneficiate steel for international markets, and partnering with the HDGASA provides essential guidance, protection, and expertise on corrosion control and quality specifications.”

Leading by example in global projects

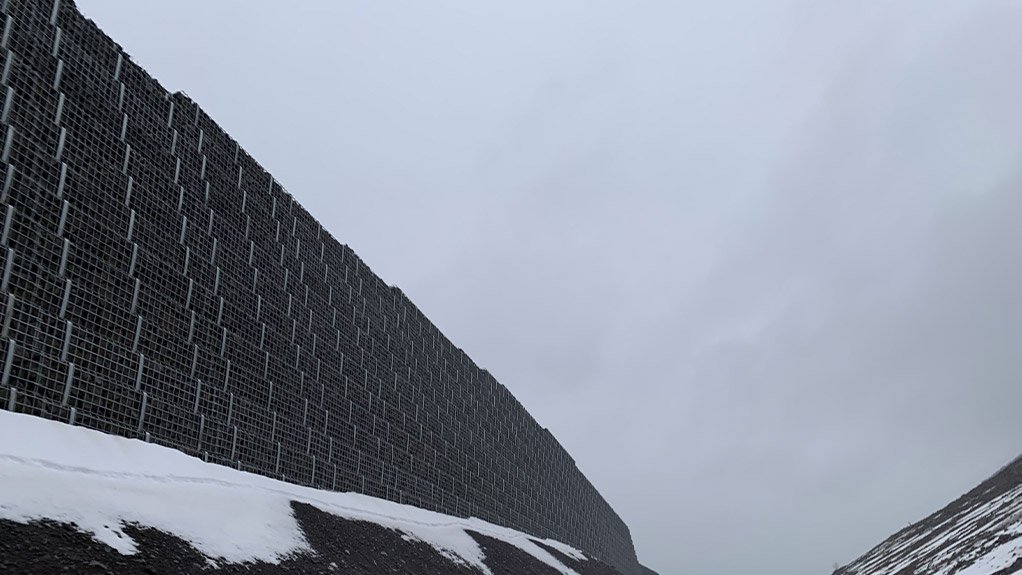

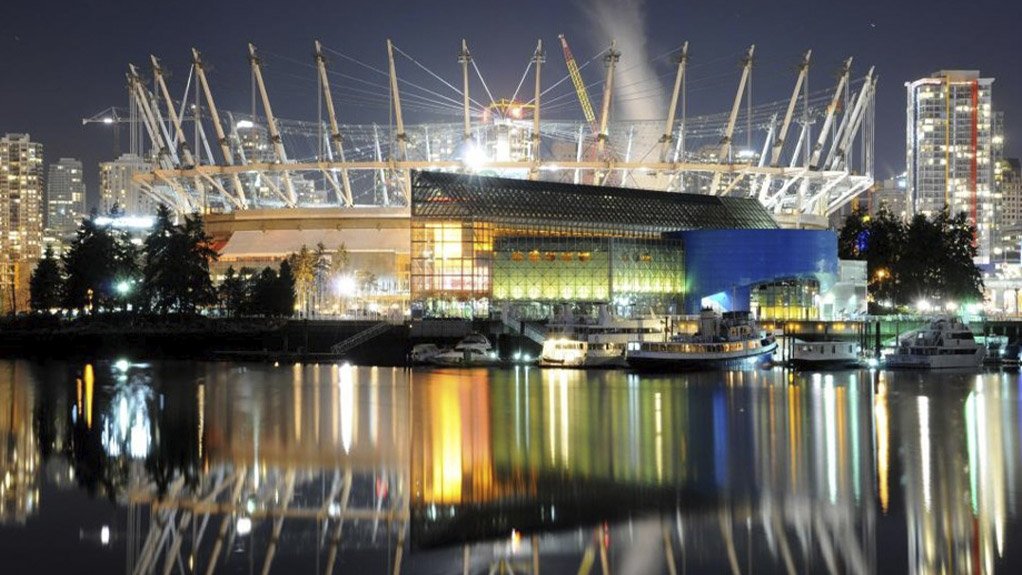

Rand York’s four decades of excellence are evident in its contributions to iconic structures worldwide: the refurbished Sydney Harbour Bridge, the London Bridge, the roof of the BC Place Vancouver stadium (hosted of the FIFA Women’s World Cup) and innovative avalanche protection walls in Iceland.

“We have done extensive work in Iceland. We supplied steel facing with an integrated basket made from 10 and 12mm wire to create an extraordinary, mechanically stabilised wall to counter a once-in-a-100-years avalanche. Just six months later, that avalanche arrived and it did exactly what it had to,” Corbett explains.

The company excels in high tensile, niche products crafted from premium materials. Corbett says that no other local firm exports more galvanized sections than Rand York:

“We use specialised steel grades with high tensile strength, excellent elongation, and chemical profiles optimised for hot dip galvanizing. Several bespoke sections are rolled exclusively for us, followed by in-house fabrication, including cutting, punching, bending, and welding.”

Rand York is South Africa’s leading supplier of hollow drill steel, collaborating closely with global mining original equipment manufacturers (OEMs). Its mining portfolio also includes steel shouldered pipe couplings for underground water and air reticulation, and through its Technobolt division, the company supplies rock anchors and bolts for roof support. Ground stabilisation in the civil engineering space is also an important business for Rand York.

“A prime local example is the ongoing upgrade of the EB Cloete interchange on the N3 Durban outskirts, where we have supplied thousands of ground anchors,” he advises.

Exporting to 65 countries across all continents, Rand York provides steel profiles for mechanically stabilised walls - the most prevalent civil engineering design in modern history. Locally, these can be recognised by their interlocking panels at the Marlborough interchange and many other Gautrain locations. The company maintains a strong partnership with GeoQuest, global experts in such systems, where hot dip galvanizing is essential for permanent structures with design lives exceeding 50 years.

In agriculture, Rand York supplies hot-rolled steel sections, fabricated and galvanized for greenhouses, meeting the sector’s growing demand for durable solutions.

Rand York’s galvanizing is handled by long-term partner Transvaal Galvanisers, fostering a decades-long collaboration built on trust and precision.

Corrosion control expertise

Corrosion protection is at the heart of Rand York’s operations. The company offers a comprehensive range of solutions, including hot dip galvanizing, duplex coatings (such as epoxy), bitumen coating and Denso wrapping. “Hot dip galvanizing represents 80% of our corrosion protection work,” says Divisional Manager Kingsley Corbett. “We are frequently consulted by OEM clients on project-specific requirements to comply with global specifications, especially in highly corrosive environments.”

The HDGASA: a beacon of support

The HDGASA plays a crucial role in Rand York’s success, providing up-to-date insights on international standards from Canada, Australia, Japan, and beyond. “They are attuned to every nuance and variation in specifications, which has been invaluable for our overseas and domestic clients,” Justin Corbett emphasises.

Training is another key benefit. Kingsley Corbett, a qualified Level 2 Galvanizing Inspector through HDGASA programmes, advises on standards and clarifies distinctions between aesthetics and functionality. “Specifications might permit a small black or uncoated spot, but confusion often arises - HDGASA training demystifies this,” he says.

Over 30 shopfloor staff have completed Level 1 training, empowering them to identify potential issues early and ensure product integrity.

The HDGASA’s objective third-party mediation has also proven vital. In one instance, a shipment exposed to high humidity during transit developed white rust, risking rejection. HDGASA experts Robin Clarke and Anthony Botha diagnosed the cause and outlined simple rectifying steps, salvaging the consignment.

“In essence, the HDGASA has been pivotal to our business: a true lighthouse offering trusted knowledge, advice, and training,” Justin Corbett concludes.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation