The lube kitchen series part 13: Extreme Pressure (EP) additives – the additives that thrive under pressure

This article has been supplied.

By; Steven Lumley - technical manager, WearCheck

(Virtual Showroom) Continuing the journey through the world of anti-wear additives with condition monitoring specialist company, WearCheck, this final instalment of the lube kitchen series looks at additives that work their magic under pressure – Extreme Pressure (EP) additives - the other metal guardians in your oil.

The development of EP additives gained momentum during World War II, as high-performance lubricants were needed for lubricate military hardware. Sulphur-based EP additives emerged as a significant advancement in additive chemistry during this period.

During the 1950s and 60s, the use of chlorine-based compounds like chlorinated paraffins became widespread, but as the years rolled on, the use of chlorine-based additives declined due to environmental and health concerns.

EP additives work their magic at the beginning of the Stribeck Curve, where lubrication conditions are either in the mixed-lubrication or boundary-lubrication regimes. However, EP additives are generally more critical in boundary-lubrication conditions than in mixed lubrication.

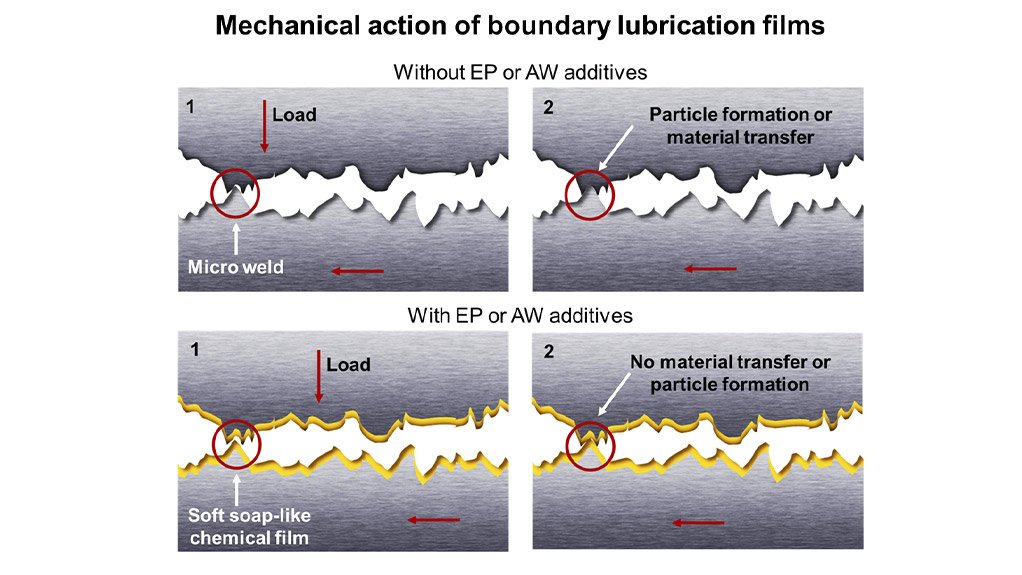

In boundary-lubrication conditions, the interacting surfaces are in direct contact without a sufficient oil film separating them. EP additives play a crucial role by preventing adhesive wear and protecting components when the lubricating oil is unable to maintain an adequate film thickness.

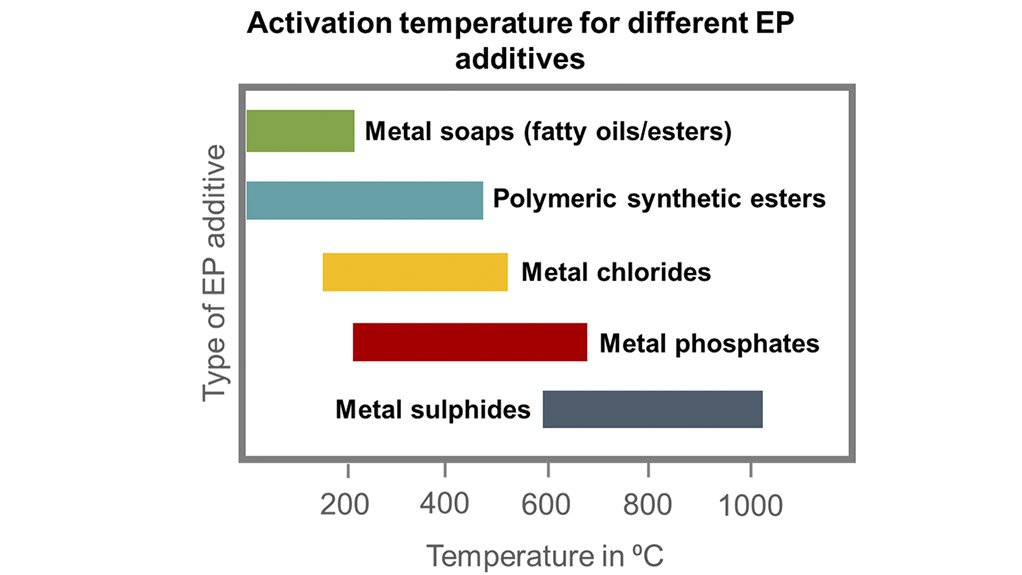

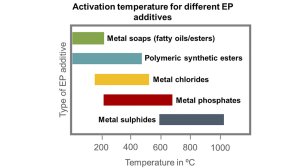

They are activated at high loads and by the high contact temperatures that are created in boundary-lubrication conditions. They are typically used in gear oils and give those oils that unique, strong sulphur smell.

These additives are more chemically aggressive than anti-wear additives. They react chemically with metal (iron) surfaces to form a sacrificial surface film that prevents the welding and seizure of opposing asperities caused by metal-to-metal contact (adhesive wear).

Let’s look at the common types of EP additives.

Sulphur-based compounds form metal sulphide films, and are among the most widely used and effective EP additives. They rely on tribochemical reactions to create these protective metal sulphide films. Under high pressure between metal surfaces, the sulphur bonds in the additives break, releasing reactive sulphur. This sulphur then reacts with metal atoms to form metal sulphides, which have a layered crystalline structure. This structure creates a lubricating film with high adhesion, low shear-strength, and the ability to replenish rapidly as it wears away

Sulphur-based EP additives can be categorised into two types:

Active Sulphur EP Additives: these are highly reactive and readily interact with metal surfaces, especially at elevated temperatures. They form a protective metal sulphide film that prevents metal-to-metal contact under extreme pressure. However, active sulphur can also cause corrosion of softer metals, such as copper and brass.

Inactive Sulphur EP Additives: these are less reactive at typical operating temperatures and do not aggressively attack metal surfaces. They provide EP protection by gradually forming protective layers through slower chemical reactions, without aggressively bonding with the metal surface under standard conditions.

Phosphorus-based compounds form metal phosphate films, creating a smooth polyphosphate layer that offers good wear resistance and load-bearing capacity. While these films are typically thicker, they are less durable than sulphur-based films and may have reduced effectiveness at higher temperatures.

Chlorine-based compounds form iron chloride films but, as mentioned, the use of these additives has significantly declined due to toxicity concerns.

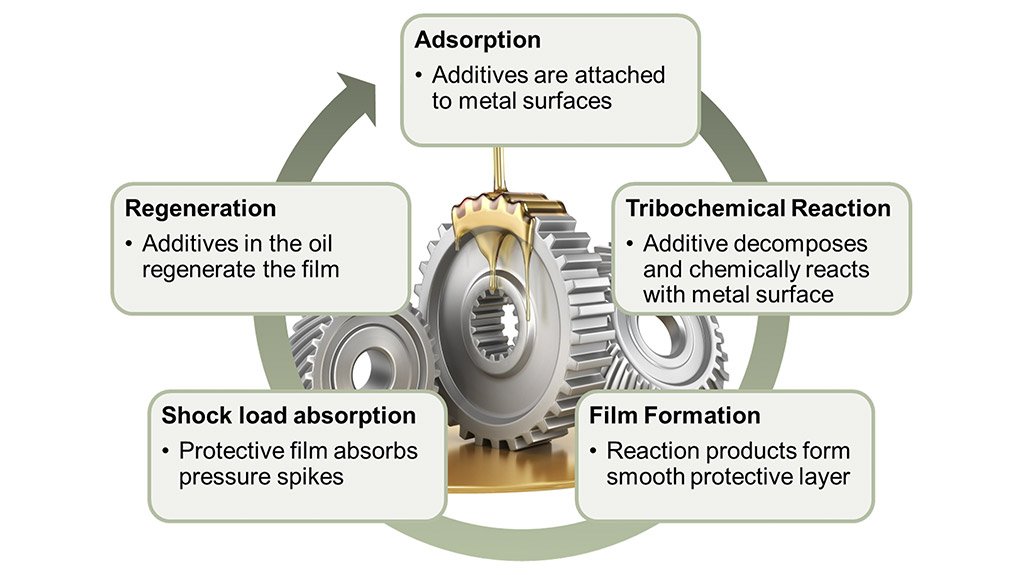

EP additives protect load-bearing surfaces through a series of reactions over the oil's lifecycle. The process generally involves the following key steps:

Adsorption – additive molecules are attracted to metal surfaces through polar interactions.

Tribochemical Reaction – under extreme pressure, the additive molecules decompose and chemically react with the metal surface, forming a protective, inorganic compound.

Film Formation – depending on the type of EP additive, the reaction products form a smooth protective layer, which may be crystalline or amorphous in structure. This film reduces friction and metal-to-metal contact, providing a smooth, lubricating film to protect surfaces under high pressure.

Shock Load Absorption – the protective film, whether crystalline or amorphous, absorbs pressure spikes and helps reduce mechanical stress on the base-oil film, preventing metal-to-metal contact.

Regeneration – as the protective films wear off, the additives in the oil regenerate the film, maintaining ongoing protection.

The exact chemical reactions between the additive and metal depend on both the type of EP additive and the composition of the base metal but in essence EP additives sacrifice themselves to form inorganic solid films on the metal surface, that delivers wear protection under boundary-lubrication conditions. They’re the true specialists in boundary conditions—chemically reactive, mechanically effective, and always ready to shine when the pressure’s on.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation