Thos Begbie & Co

Thos Begbie & Co was established in 1887 by Scottish marine engineer and pioneer Thomas Begbie, in the newly proclaimed gold-rush town of Johannesburg.

A management buyout in 1989 further boosted Thos Begbie’s growth into becoming a world-class manufacturing, foundry and heavy engineering company that is the preferred vendor to smelters in 23 countries across the globe.

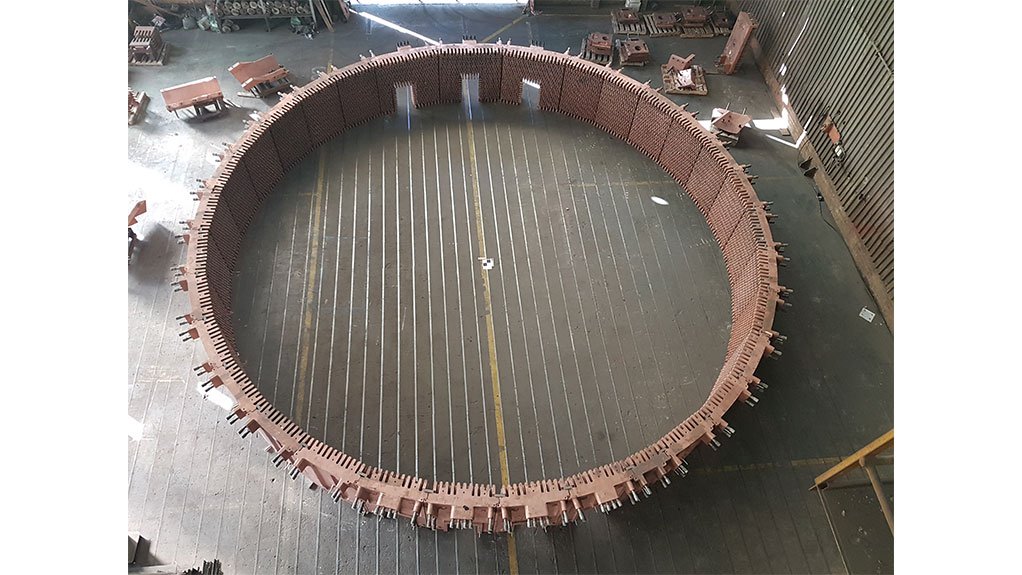

Thos Begbie specialises in providing water-cooled pure copper elements to the pyrometallurgical industry for wall and roof components of furnaces. Every item is produced according to exacting standards and specifications at the company’s ISO 9001: 2015 certified manufacturing facilities in Middelburg.

The fully equipped 7 000 m2 foundry features six overhead cranes and seven furnaces, four of which are gas-fired and three induction, allowing single castings up to 17 t in non-ferrous metals and 2.5 t in ferrous.

Thos Begbie boasts state-of-the-art non-destructive testing (NDT) testing facilities unique among its competitors worldwide and provides a wide range of in-house capabilities and services, including:

- Computer-aided design and drawing office

- Pattern shop and tooling manufacturing

- Solidification and methoding expertise

- Pipe and tube manipulation and coil fabrication

- General fabrication and speciality welding

- Laboratory with Wet-Chem and metallurgical chemical analysis

- Modern fettling and sand-blasting plant

- Flaw-detection analysis using X-ray, ultrasound, infrared thermal imaging

- Mechanical properties pressure and flow-rate testing

Graphite Freezeline Solutions (GFS) is the latest addition to the Thos Begbie Holdings Group, offering products and solutions for efficient and heat-resistant refractory materials in carbon, micropore carbon and various grades of synthetic graphite – machined to tight tolerances to suit customers’ specific requirements.

Situated on the Thos Begbie site in Middelburg, the GFS facility is equipped with various computerised numerical control, milling and routing equipment to ensure accuracy and quality repeatability.

Over the past two decades Thos Begbie has been the preferred supplier of water-cooled copper coolers, with the graphite and carbon bricks applied to copper coolers on the Thos Begbie site before being shipped to a furnace site. Now, with GFS on site, Thos Begbie is able to provide a one-stop shop to the international industry.

The graphite application facilitates a freezeline or accretion of frozen slag layer that protects the furnace shell and copper coolers from corrosion and abrasion, thereby extending the life of a furnace. Together with the cooling effect of the copper coolers, the graphite lining and the accretion layer helps to prevent excessive heat loss and unnecessary energy wastage. The freezeline or accretion layer increases or decreases in thickness until furnace conditions stabilise. Newly applied graphite does not require extensive curing, ensuring immediate savings and return to full production capacity. In addition, very little maintenance is required on graphite linings during operation.

GFS offers a range of benefits, including:

• Unlimited types and grades of graphite and carbon

• Raw material can be accurately machined to any requirement

• Over 20 years’ experience in applying graphite to copper coolers

• Over 27 years’ experience in providing on-site application advice

• Site is ISO-certified, with built-in inspection and NDT facilities

• A global footprint, supplying to 23 countries

• Sourcing the best material for specific applications, ensuring continuous improvement and reducing waste, ensures exceptionally competitive prices

Thos Begbie & Co’s long history, outstanding reputation, and substantial experience in the fields of manufacturing of pyrometallurgical components, general engineering and machining and tube manipulation have made it the industry leader in the supply of a vast range of cast and machined engineering products for the exacting requirements of the mining and smelting industry.

Operating 24/7, furnace operators worldwide rely on Thos Begbie & Co to provide products and services of the highest standards, anywhere and anytime.

T: (013) 246 9100

E : jurgen.dercksen@thosbegbie.com

E: herculesv@thosbegbie.com

E: Esli.Bantjes@thosbegbie.com

W: www.thosbegbie.com

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation