TIMining brings situational awareness to mining operations from any smart device, anytime, anywhere

While digital transformation has rocked the mining industry, the pandemic accelerated the shift to remote working, amplifying the demand for state-of-the-art technology to keep teams virtually connected to on-the-ground operations.

TIMining, a global technology company dedicated to the mining industry with offices in Santiago and Perth, has multiple software platforms for different processes being used at some of the world’s largest open pit mines operated by BHP, Anglo American, Codelco, Arcelor Mittal, Teck, and others.

Transforming data into insights

TIMining has just released its latest technology and innovation, TIMA (TIMining Aware), a system that equips decision makers with hand-held technology to determine the status of operations through 3D visualisations.

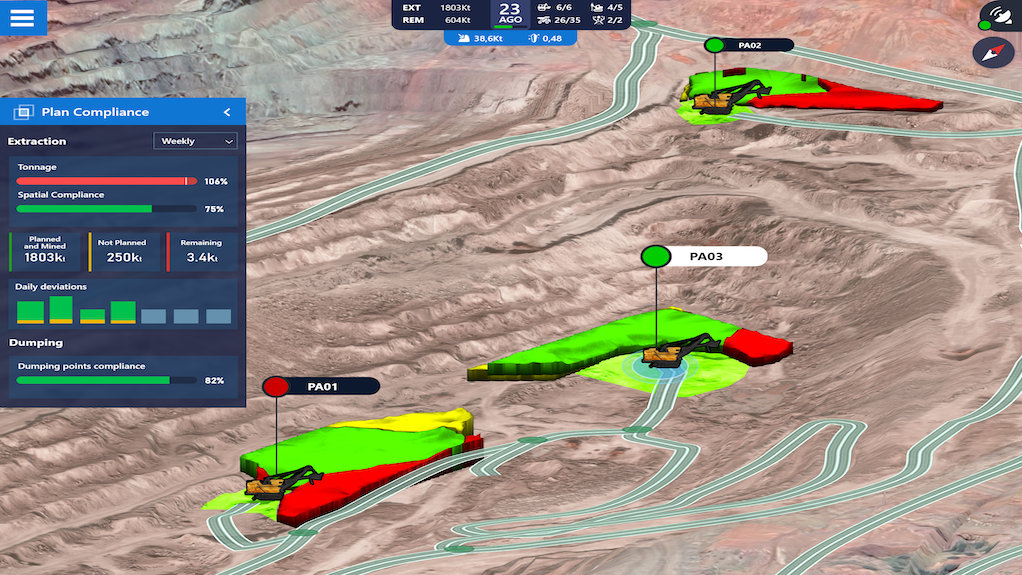

TIMA is software that transforms data into insights to support mining experts making crucial daily decisions. The platform uses data from operational systems, state-of the-art analytics and algorithms to create real-time visualisation of operations.

Increased awareness, reduced expenses

The pandemic propelled a removal of non-essential staff from mine operations; with management and supervisor level staff working remotely companies have experienced increases in productivity and massive reductions in travel time and costs.

“Now executives need to help their companies be as productive as before, provide their professionals with cutting edge technology and tools for remote collaboration – and that’s what this solution is about,” says Nicolas Jubera, CEO, TIMining.

TIMA provides access to real-time information; updated mine surfaces, online monitoring of mine plan compliance, equipment and hauling fleet visualisation, location, speed and status performance maps, and is accessible from any smart device, anywhere in the world.

User - focused design

“It’s like a distributed remote control centre in your pocket. And it’s designed around the user – it presents the user with the precise information needed for situational awareness and insights, in a seamless, intuitive way. Technology focused design overwhelms people: too many systems, too many screens, too many logins.”

With a 3D digital twin representation of reality, users can navigate through time and explore current and past events to see exactly what happened at the mine – and when. And with simulation and AI, predict the future and present options to decision makers.

“You can see what is happening at the mine – you can see the paths, where your equipment is, if the equipment is in the right place, and how you are doing according to planning in real time” Jubera explains.

“Used on a mine site, TIMA can be used to gain situational awareness in a kind of augmented reality, as you can pull out your smartphone and see where you are and data around you. That’s the concept of situational awareness – having a clear idea about what is happening at the mine so they can make timely decisions.”

The software can be tailored for executives, engineers and integrated remote control centres and can adapt to unique technology policies in a cloud, hybrid, or on premises implementation.

Synching teams

The software can synch with teams working remotely in all corners of the world.

Fewer site visits are required with TIMA as users can gain access to a pool of worldwide talent and expertise that is hard to find on the ground.

“Now with remote working, it’s easier – you can have an expert in Brisbane helping your mine in Africa, for example. These experts used to travel the world – now it’s not so easy. This is a great opportunity to deploy talent across sites,” Jubera says.

TIMA software is about optimising human capital and organisational effectiveness and which also ticks the productivity and safety boxes while providing tools for people to connect and communicate remotely in real-time.”

“We’re not talking about the future anymore,” says Jubera, “it’s here.”

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation