Welding Alloys South Africa & KRAM Engineering

As a market leader in engineered wear-protection solutions and flux-cored welding wire technology, Welding Alloys South Africa (WASA) has been servicing the sub-Saharan Africa market since 1976. WASA is part of the Welding Alloys group, which covers more than 150 countries through a network of 30 subsidiaries worldwide.

Since 2016, the company has, together with its new subsidiary, KRAM Engineering, supplied the mining, cement, power, petrochemicals and steel industries with abrasion-, impact- and corrosion-protection services to reduce cost of ownership through extended life, and decrease downtime and maintenance costs.

KRAM Engineering offers refurbishment and wear linings in basalt and alumina ceramics; silicon, tungsten carbide, rubber and epoxy wearing compounds; idlers; ultrahigh-molecular-weight polyethylene and hydro cyclones.

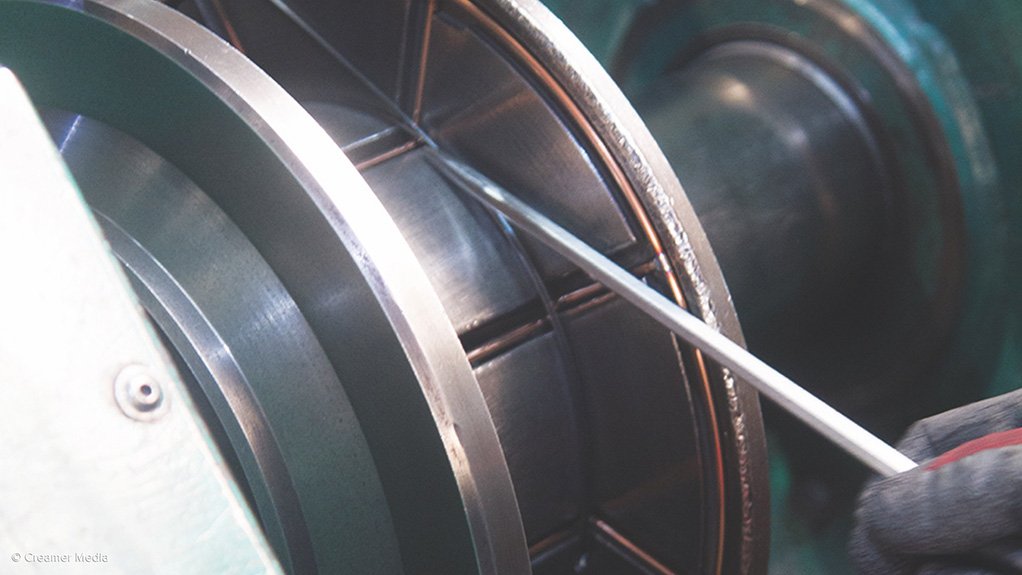

Operating from its facilities in Benoni and Roodepoort, Gauteng, WASA has 147 employees and is equipped with wire manufacturing, automated plate-, pipe-, roller-press- and table-welding equipment. The company also offers a range of flux-cored welding wire and turnkey fabrication in chromium-carbide overlay.

Applications of its product offering include coal transport, mining and quarrying equipment, excavator buckets, cyclones, feeders, chutes, hopper bins, pulley lagging, launders, pulverised coal systems, thickeners, screw conveyors, crushers, steel mill rolls, sugar cane milling, caterpillar rollers and tracks, valves and forge hammers.

WASA is ISO 9001- and ISO 3834-3-accredited.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation