Company provides energy efficient solutions for customers

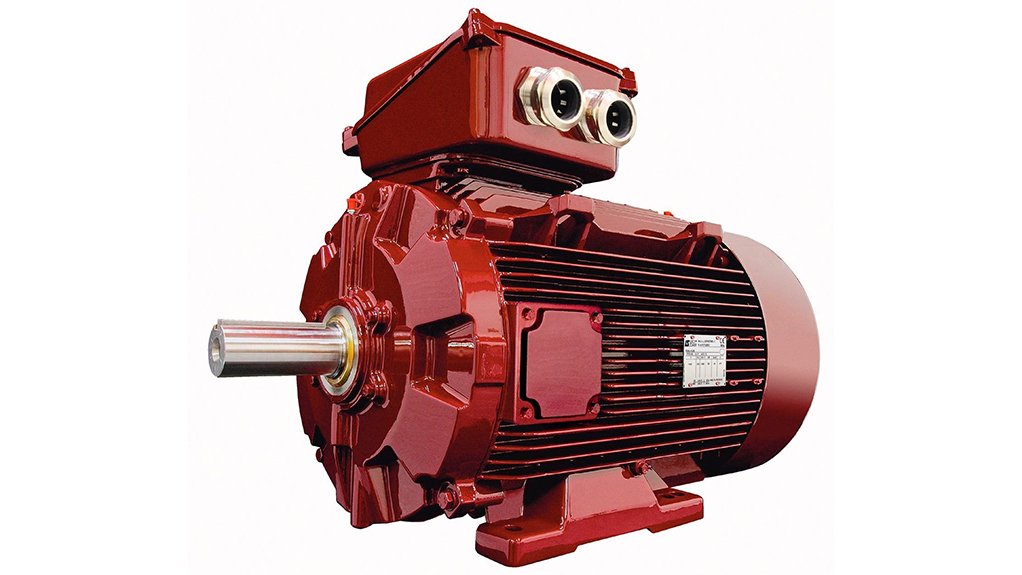

HIGH EFFICIENCY The Dyneo motor-drive unit ensures high efficiency levels over the whole operating speed range, especially at speeds below the synchronous speed

Electric motors company Vert Energy – exclusive distributors in Southern Africa of electric motor manufacturer Leroy Somer – is committed to providing energy-saving solutions for its diverse customer base.

Critical challenges facing industry include finding the most efficient ways to minimise energy consumption and reduce carbon emissions, with no compromise on productivity and safety, says Vert Energy MD Grant Robertson.

With the implementation of variable speed and the optimisation of mechanical speed reduction efficiencies, the maximum saving of electricity consumption is obtained in any power transmission system.

“Feedback from our customers indicates that combining Leroy Somer and Dyneo permanent magnet technology with variable-speed technologies, has not only significantly reduced energy consumption, but has also led to a good return on investment and lower overall cost of ownership.”

Through Dyneo permanent magnet solutions – with sensorless control and interchangeability with standard international electrotechnical commission mechanisms – the company is able to offer its customers the benefits of high performance of permanent magnet motors, with the simplicity of mounting and installation equivalent to traditional asynchronous motors.

The Dyneo range, which is manufactured in France, includes the option of an aluminium frame size up to 500 kW.

Robertson notes that benefits include European quality standards, with certified ratings and efficiencies from approved regulatory bodies, and an improved aesthetic finish as opposed to a rugged cast-iron body. Another benefit includes removable feet for multi-mounted applications in certain frame sizes, better heat dissipation than with traditional cast-iron frames and fewer losses owing to improved thermal characteristics.

Meanwhile, Leroy Somer’s Dyneo permanent magnet solutions enable the construction of lighter units with a reduced footprint, which is particularly beneficial to original-equipment manufacturers (OEMs).

He adds that the compact design and fewer mechanical components mean a reduced size of the chassis supporting the motor. This design also facilitates easy installation of the motor on-site, the simplification of lifting equipment required and reduced transport costs.

The Dyneo motor-drive unit ensures high efficiency levels over the whole operating speed range, especially at speeds below the synchronous speed, where efficiency is higher than with asynchronous motors.

Dyneo technology, which also guarantees optimum torque over wide speed ranges without de-rating or forced ventilation, significantly improves the drive’s efficiency and enhances specific output power, offering better performance than conventional technologies.

Additionally, Robertson notes that other important features include adaptation of the motor speed to the speed of the driven machine, improved performance of the driven machine by increasing its speed, potential elimination of gearing, a low rotor temperature-rise and better bearing performance.

LSRPM (IP55) /PLSRPM (IP23) permanent magnet motors are built using the same high quality European mechanical components as Leroy Somer asynchronous motors, to offer reliability and flexibility. This interchangeable range, with standard dimensions in terms of frame size, flange and shaft extension, provides an immediate energy-efficient solution, without the need for modification of the existing system.

Advantages of the sensorless control design include less wiring and fewer connections for simplicity of installation. Encoders or long cable lengths are not required and there is no need for concern about environmental constraints, like vibration, temperature and abrasive dust, affecting the machine.

These high-performance, energy-efficient variable speed solutions – designed for applications requiring high torque at high speed – enhance power transmission performance in pumping, ventilation, compression, conveying, extrusion, process control and generators.

Further, in a recent project, a variable-speed screw compressor equipped with a Dyneo permanent magnet solution was added to the existing four fixed-speed screw compressors used in refrigeration, during the production of beer.

“This upgrade has achieved energy savings of 600 000 kWh/y, an increase in the maximum speed and improved performance of the system.”

In a drinking water plant, the replacement of two asynchronous motors with a single 350 kW Dineo motor-drive unit, has reduced energy consumption by 10% for every cubic metre transferred. The pump has also increased water flow by 15%. The payback period for this system was 14 months.

Another successful installation formed part of a modernisation programme at a rubber extrusion facility, where Vert Energy’s Dyneo solution has eliminated the machine off-centre pulley and belt system, explains Robertson. The motor can withstand operation in 50 °C above ambient temperature and because of its compact design, it has been installed under the screw.

The LSRPM Dyneo solution was selected for a ventilation axial fan upgrade for air treatment towers, owing to its high specific output power and direct coupling to the impeller. This system has an optimised motor-drive assembly, with sensorless control, ensuring high efficiency over the entire speed range.

Meanwhile, as part of its commitment to ongoing technological advancement, Leroy Somer has developed the ‘Energy Savings Advisor’ to help customers identify improved energy savings in their respective application.

Vert Energy’s service to the electro-mechanical power transmission sector, encompasses the supply of dependable products that combine high performance, energy efficiency, reduced downtime and extended service life, to meet stringent quality, safety and environmental standards.

Field services include re-assembly, installation and commissioning, inspections and diagnostics, as well as on-site maintenance and repair work. Vert Energy’s factory and OEM-trained technicians travel throughout Africa to assist customers with any electro-mechanical breakdown situation or routine preventative maintenance procedures.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation