Company reaps benefits of manufacturing locally

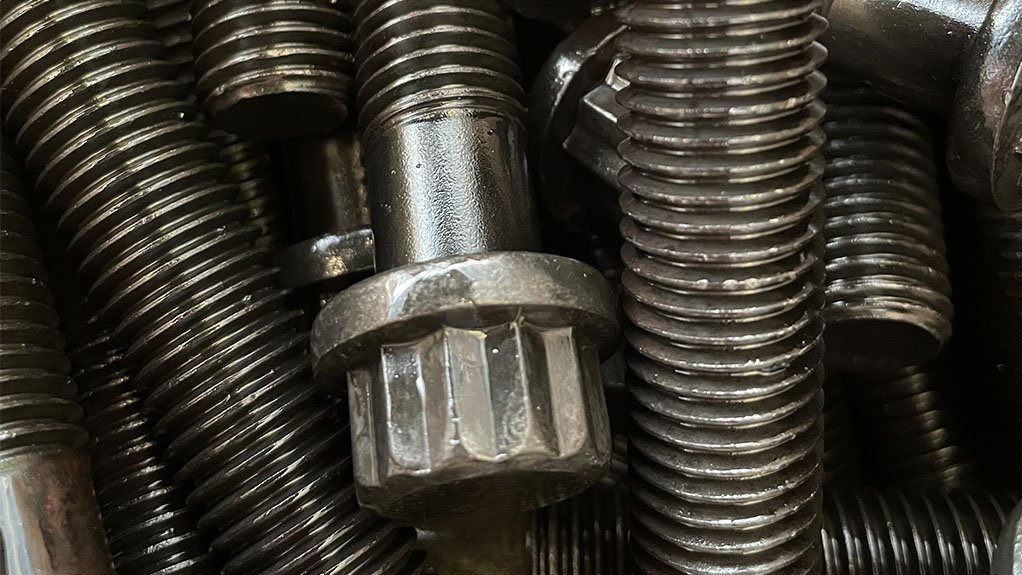

LOCAL IS LEKKER Local manufacturing enables Impala Bolt and Nut to achieve quicker manufacturing turnaround times and lower stocks of finished goods, in addition to meeting customers’ local-content requirements

Sourcing fasteners locally rather than importing them enables customers to avoid potential pitfalls, including logistical delays, erratic steel prices and shipping costs, says fasteners manufacturer Impala Bolt & Nut MD Derek Cohen.

South Africa requires investment in the renewable-energy, mining and automotive sectors and the fasteners industry can, subsequently, benefit from infrastructure growth, as building projects require fasteners.

However, Cohen adds that potential investors in local industries require manageable risk, certainty and long-term consistency, which can be achieved with stable government policy and protection from cheap imports.

“The only way South Africa can succeed is if we educate and employ people locally which can be done only with government support and investment. At Impala Bolt & Nut, we are committed to using locally produced raw materials and contributing to the future success of the country.”

The company manufactures its fasteners locally through investing in new plant equipment and systems, and trains staff in-house across various disciplines to expand its manufacturing capabilities and capacity.

Manufacturing products locally enables the company to achieve quicker manufacturing turnaround times and lower stocks of finished goods, in addition to meeting customers’ local-content requirements.

Impala Bolt & Nut is the only fastener manufacturer in South Africa that is certified to International Automotive Task Force 16949 standards, which enables players in industries such as the automotive sector to source products locally – therefore supporting government incentives for local procurement.

Further, the company has released new product ranges this year for the automotive sector, including special bolts with nonstandard head shapes and sizes.

“Moving forward, we aim to continue investing in plant equipment, the training of staff and manufacturing products locally as import substitutes,” concludes Cohen.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation