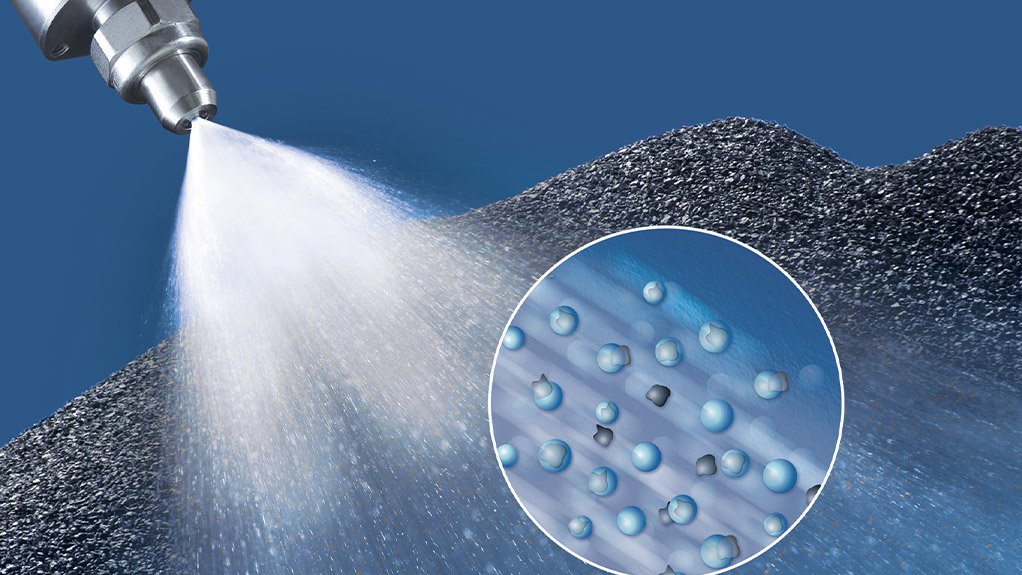

Details of a dust suppression system

What is dust suppression?

Dust suppression is a process used to reduce airborne dust particles. Dust suppression systems spray a fine mist of water either using hydraulic misting nozzles, or air atomizing nozzles in different environments such as mines, steel plants, paper plants and quarries. Monitor Engineering, sole agents for Spraying Systems Co USA, have been importing spray nozzles and spray systems for over 50 years, supplying dust suppression systems and dust suppression nozzles for a wide range of dust suppression applications to various mines and industries in Southern Africa.

Dust suppression fundamentals

Dust can be challenging to manage once it is airborne. Therefore, any dust suppression solution should consist of dust control (wetting the product before dust becomes airborne) and dust suppression (capturing airborne dust).

Dust suppression uses water to reduce the number of dust particles becoming airborne in many different areas on the plant, starting at the tip, through the crusher onto conveyor transfer points, screening and stockpiles. Spraying dust with water increases the weight of each dust particle, making it harder for it to become airborne. Dust suppression nozzles come in various shapes and sizes from full cone, hollow cone, flat spray nozzles, misting nozzles and air atomizing nozzles. It is extremely important that the correct nozzle and quantity is selected for each application. It is not as simple as one size fits all.

What are the benefits of using dust suppression?

There are many advantages to using dust suppression in environments prone to high volumes of dust. In places like mines and quarries, dust can pose health and safety risks for workers, and suppressing dust levels on-site helps to protect both people and equipment. Reducing dust levels, in turn, reduces the risk of respiratory factors, alongside improving visibility on-site, as well as forced mine closures due to non compliance. Investing in dust suppression systems can be financially beneficial, potentially saving on maintenance and clean-up costs in the future.

Which dust suppression system and nozzle is right for me?

At Monitor Engineering, we offer a number of dust suppression system solutions, from either just supplying spray nozzles, or spray bars with nozzles and strainers, to supplying complete plug and play dust suppression kits, including Hydra-cell high pressure pumps, tanks, strainers and spray bars, and hydraulic hose. We also offer dust suppression system installation.

Our onsite audits by our experienced sales engineers will assist you in determining which solution is best for your dust suppression needs. In these audits we determine which kind of dust suppression nozzles will work best, be it a full cone, hollow cone or misting nozzle, as well as whether we need to use low or high pressure. This will be determined by the product being mined, and the prevailing site conditions.

When it comes to choosing a suitable dust suppression system for your needs, make sure you contact a company that has a good knowledge of the various spray nozzles that can and should be used, and has a proven track record in the dust suppression systems industry.

Monitor Engineering Pty Ltd

011 618 3860

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation