Effective lubrication key to smooth operation of electric motors

SPONSORED POST (Virtual Showroom): Lubrication improvements are said to significantly increase the reliability of electric motors and premature motor failure can most often be attributed to bearing failure because of inefficient lubrication.

Lubricants have a finite lifespan and re-lubrication is essential for long-term motor reliability, however, manual re-lubrication can be ineffective. Human error can lead to problems such as the application of the wrong grease, applying too much grease, or not lubricating all areas consistently. Manual greasing is also usually undertaken while equipment is stopped, so the motor is cold. Under these conditions older and colder grease may block the entry of new grease into the bearing and the grease may instead move into the motor internals.

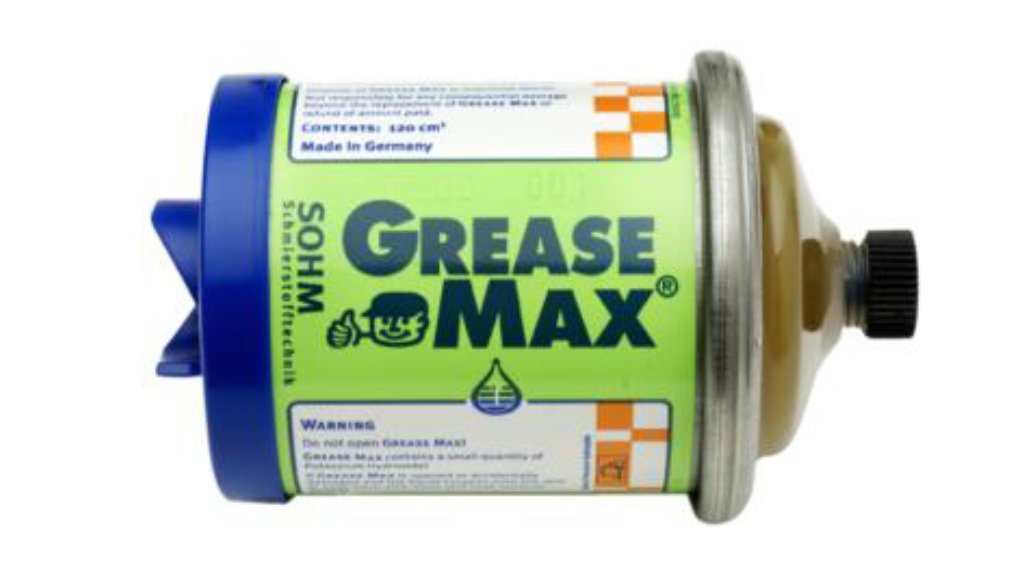

GreaseMax continuous lubrication prevents the problems that arise because of manual re-lubrication. The solution offers the best lubrication results for improved bearing life. In addition, allowing for the re-greasing of a motor while it is running leads to a more effective and controlled result.

GreaseMax improves bearing life and reduces the possible application of excess grease and contamination of the motor internals. Using GreaseMax also ensures that the correct grease is used and reduces the potential of foreign matter contamination from dirty grease nipples or inconsistent lubricant application.

For more information, visit Creamer Media’s Virtual Showroom

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation