Environment-friendly drive design

Coating-free drives manufactured with the use of responsibly-sourced raw materials have been designed with a focus on the environment.

SEW-EURODRIVE has developed its ECO2 design to offer drives with no coatings or solvents used on the outer surfaces of the units, making them more environment-friendly and reducing the cost of manufacture and assembly.

“Our markets are increasingly demanding eco-friendly products, and we responded with our sustainable coating-free drives and a responsible use of raw materials,” says SEW-EURODRIVE national sales and marketing manager Jonathan McKey. “Our ECO2 design allows customers to select the specifications they need, while meeting their goals in terms of both ecology and economy.”

McKey notes that the drive components can also be recycled more efficiently and sustainably at the end of their lifecycle. He points out that the ECO2 option is suitable for applications where drives are operated in closed rooms, and where they are well protected from cold, heat and moisture.

“The metallic surfaces of ECO2 products are predominantly aluminium and are not prone to corrosion under normal ambient conditions, which makes them especially durable,” he explains. “In fact, aluminium reacts with oxygen to form a particle, creating a thin protective layer in a dry neutral environment – protecting the outer surface from corrosion.”

The drives are suited to indoor spaces with a maximum humidity of 60%, where ambient temperatures range between minus 20°C to 60°C. The product meets the requirements of ISO 12944 corrosivity category C1.

“Our manufacturing process for ECO2 drives is more energy-efficient as there is no need for the drying stages, and also no need for recoating after repairs,” says McKey. “With lower CO2 emissions in production, there are fewer harmful greenhouse gases released thanks to having no coatings on these units.”

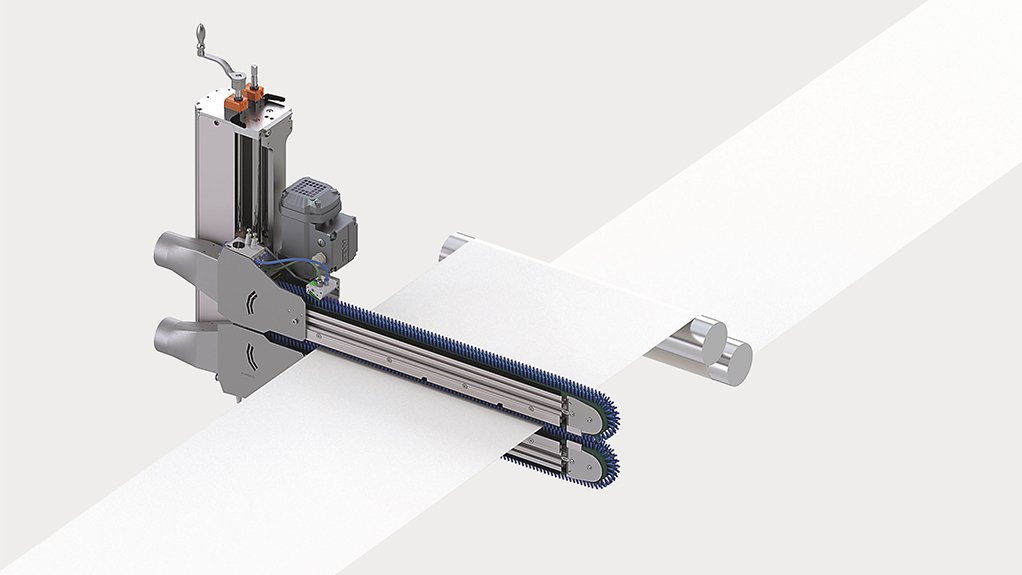

The drives are available in multiple designs and configurations and applications include cleaning systems, conveyor belts and dispensing systems for powders and granules.

Gear unit sizes include 07, 17 and 27 in helical gear units, 27 in parallel-shaft helical gear units, 19 and 29 in helical-bevel gear units, and a variety of SPIROPLAN right angle gear unit sizes.

“ECO2 drives are available with all additional electrical features, number of poles, power ratings, voltages and frequencies; the gear motors also hold all the relevant approvals and certifications,” concludes McKey.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation