Flsmidth’s Rotor/Stator Combination Takes Forced Air Flotation To The Next Step

This article has been supplied.

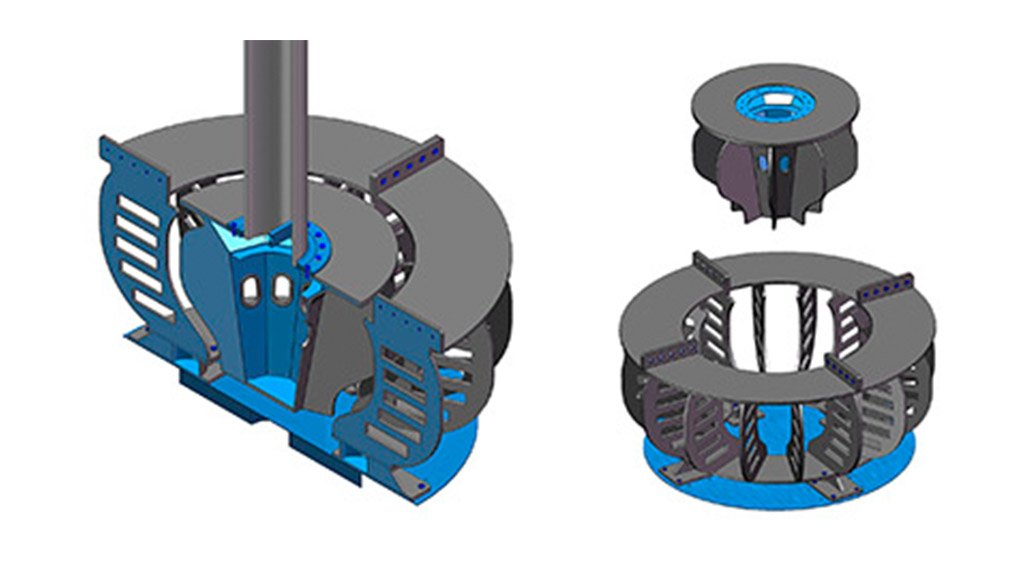

Company Announcement - The FLSmidth® nextSTEP™ rotor/stator combination represents the newest design in forced-air flotation technology and offers major advantages to the market. The latest solution demonstrates significant improvement in both metallurgical performance and energy efficiency over traditional forced-air designs. The design of the stator was reinvented in the development of the nextSTEP™. Slots were added to the stator, making energy dissipation more uniform which results in a higher probability of bubble particle contact during the flotation process.

Dariusz Lelinski, flotation development manager at FLSmidth, says that the FLSmidth® nextSTEP™ rotor/stator offers the lowest operating power of any forced-air flotation mechanism on the market and provides significantly better metallurgical performance. This is mainly due to the slots in the stator as well as the shape of the rotor, which produces a wider stream of slurry with bubbles leaving the rotor blades. Adding slots to the stator increases recovery and boosts overall flotation efficiency, in part due to the higher energy dissipation that occurs. Matching the shape of the rotor with the shape of the stator has facilitated better pumping performance and ensured more efficient use of energy within the cell itself. The perfect matching of the rotor and stator ensures that the widest possible flow is delivered and the highest area of stator is utilised. In addition, a power consumption saving of at least 15% can be readily achieved.

The superior metallurgical performance of the nextSTEP™ machine produces an increase of up to 5% in recovery rates, a result of the dramatic improvements in the mineral-bubble attachment rates. Furthermore, it provides stronger air dispersion near the rotor/stator region as well as increased pumping below the rotor.

“In addition to the increased performance and lower energy consumption, it is also relevant to note that the mechanism provides better wear distribution for increased rotor/stator life. This will have a positive impact on the long term operating costs and can benefit both new and existing installations. In summary, the FLSmidth® nextSTEP™ rotor/stator has the ability to revolutionise performance in forced air flotation cells,” says Lelinski.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation