How generative design AI could flip the economics of industrial design

This article has been supplied and will be available for a limited time only on this website.

By: Jim Chappell - Global Head of AI and Advanced Analytics, AVEVA

Project design is notoriously plagued by delays and cost overruns. After all, it’s an iterative system: designing, testing, prototyping, and reworking designs based on feedback and observations. As project complexity has increased, so have inefficiencies.

Generative design artificial intelligence (GenDAI) is rewriting this narrative, as the Andritz Group is discovering. The Austrian supplier of plants, equipment and industrial systems projects it can reduce time to market and cut costs after conducting an in-depth pilot exercise to estimate pipeline routing for a plant. As part of its new cross-project database, engineers can quickly find and tap into data on piping dimensions and quantities from previous projects. The exercise showed how manhours could be slashed by close to a third (35%), revisions and rework reduced by up to a quarter (23%) and projects delivered up to 12% faster.

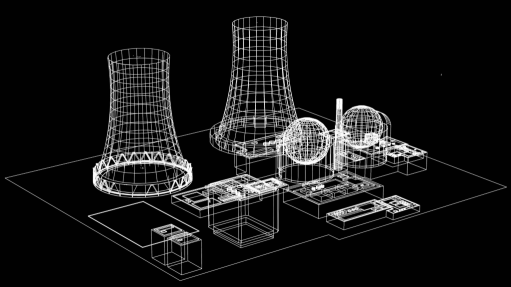

In a typical use case, GenDAI can automatically create optimized 3D pipe layouts for a new or existing factory, with preset objectives to minimize overall tube length, reduce sharp bends for higher flow, and factor in space constraints.

How GenDAI extends human ability

This cutting-edge technology augments human creativity. It uses AI’s exceptional ability to crunch massive datasets and use existing patterns to generate new designs in response to input from design experts. The application parallels current developments around producing text, images and video from simple conversational prompts.

Rather, instead of the large language models that power most consumer-facing generative AI applications, GenDAI leverages genetic algorithms, a kind of AI that mimics natural evolution, to optimize complex systems and create solutions that are out of reach of traditional design methods.

When fed specific parameters, GenDAI can quickly suggest design possibilities and create optimized solutions to meet desired outcomes. Future applications could even suggest layouts for architectural structures or for the placement of 3D heating, ventilation and air-conditioning systems. With AI doing the heavy lifting, humans can focus on selecting the best options and making strategic decisions, so the final design achieves its objectives.

How GenDAI redefines engineering outcomes

Industries today operate in a fast-paced, resource-constrained environment. GenDAI can help plug efficiency and resource gaps, while meeting sustainability targets. It also addresses workforce shortages and the loss of knowledge as experienced design engineers retire. By automating routine tasks, it enables workers to dedicate more time to innovation and higher-value activities such as problem-solving. This leads to increased productivity and a larger volume of tasks being processed efficiently.

In the piping example above, GenDAI streamlines a routine design process by factoring in key inputs, such as start and end points, spatial constraints, and pipe preferences (such as to minimizing total pipe length or the number of elbows). The tool then produces optimized routing solutions for the project at hand within a few minutes—dramatically speeding up design output by up to 20x as compared to manual design.

In industry, GenDAI has the potential to deliver outcomes across the value chain:

- Reduced waste, enhanced efficiency: Generative AI uses topology optimization—where algorithms optimize how material is distributed within a 3D space for maximum efficiency and minimum use of materials. As a result, companies can count on a faster return on investment by way of fewer project risks and lower total installed costs.

- Faster time-to-market: AI-generated simulations can replace expensive physical iterations and compress development timelines thanks to 100% clash-free designs. Down the line, industrial companies using generative AI could expedite brainstorming and development in product design, the Industry IoT Consortium says.

- Out-of-the-box innovation: GenDAI can shortcut pathways to innovation by responding to simple text prompts with a variety of design concepts and variations within a short span of time. Many of these options may not otherwise have been considered. The engineering services leader Saipem has announced its use of AI-enhanced tools to automate design iterations and reduce the time needed to create plant layouts.

- Autonomous design: We are now at the stage where different types of AI are beginning to be paired together. GenDAI and agentic AI, which can execute tasks independently, will together lead to the creation of iterative feedback systems that use real-world data to refine products continuously. Such autonomous design loops will further elevate design outcomes.

With such a broad array of applications, GenDAI could potentially even redefine the economics of industrial design. Accenture estimates that 95% of all billion-dollar projects delivered late or over budget. By accelerating efficiency and innovation across industries, GenDAI meets urgent demands for sustainability, speed and talent optimization.

As with all AI tools, human guidance will remain essential – not just to selecting parameters and guiding design strategy, but to keeping ethics and fairness at the forefront in response to real-world challenges.

As industrial companies are discovering, AI-infused engineering tools such as GenDAI are no longer just ‘nice to have’. Their ability to deliver competitive advantages offer enormous potential—but only for those companies willing to rethink how design is done, and to leverage AI’s enormous power.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation