Local product ensures efficiency

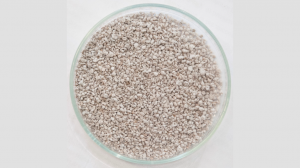

LOCALLY SOURCED The perlite-based mineral aggregate is sourced from a South African mine

CONSTRUCTION FRIENDLY Its thermal insulation properties mean that Pratliperl is capable of doubling the insulation of a double-brick wall (220 mm thick) with just 16 mm of application

ELDON KRUGER This incredible insulation value translates into significant energy and cost savings in support of sustainability

Addressing global challenges such as climate change and the growing focus on sustainable development was front of mind in the development of Pratliperl by local manufacturer Pratley, says Pratley marketing director Eldon Kruger.

“The perlite-based mineral aggregate is sourced and processed in South Africa,” says Kruger, noting that this was a key part of the company’s commitment to local sourcing, local manufacturing and sustainability, especially in terms of local production.

“By sourcing and processing Pratliperl locally, we not only enhance our product’s sustainability credentials, but we also support our community by creating jobs and developing skills,” Kruger comments, adding that the employees of the Pratliperl production facilities reside in the surrounding areas, and are the beneficiaries of Pratley’s focus on skills development and training.

Pratley consistently enhances its employees’ skills and provides them with training, either in the company’s in-house training centre or by sending them on training courses to further improve their skills.

The Pratliperl product offers a sustainable alternative for plaster and screeds, meeting stringent energy efficiency standards such as SANS 204.

Kruger explains that unlike conventional perlite aggregates, Pratliperl has a robust structure that allows it to integrate seamlessly with cement, yielding an ecofriendly, lightweight, fireproof and thermally insulating building material.

The versatility of Pratliperl, meanwhile, extends across a spectrum of applications, from plaster and lightweight floors to fireproofing and insulation solutions.

A mere 16 mm of Pratliperl plaster on each side of a wall provides the same thermal insulation as a double brick wall, meaning that the wall’s thermal insulation is increased twofold, resulting in substantial energy and cost savings.

“This incredible insulation value translates into significant energy and cost savings in support of sustainability,” Kruger remarks, underscoring the practical benefits of Pratliperl in promoting energy efficiency.

In a context where businesses face rising operational costs and challenges such as energy reliability, Pratley’s efforts to improve production methods and integrate renewable-energy sources into its operations exemplify a proactive and holistic approach to sustainability, Kruger notes.

He adds that the installation of solar power systems to reduce the company’s environmental footprint and the use of company transport for product delivery to support local production are testament to Pratley’s commitment.

“We at Pratley encourage energy efficiency and sustainability to protect our one and only home. The use of a product such as Pratliperl is the ideal simple step to reduce costs, save energy and ultimately unify our collective commitment to help protect the planet,” Kruger says.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation