Manufacturing Indaba fosters industry ties

REACHING THE RIGHT AUDIENCE The Manufacturing Indaba gives NMISA the opportunity to showcase its offerings to the manufacturing sector

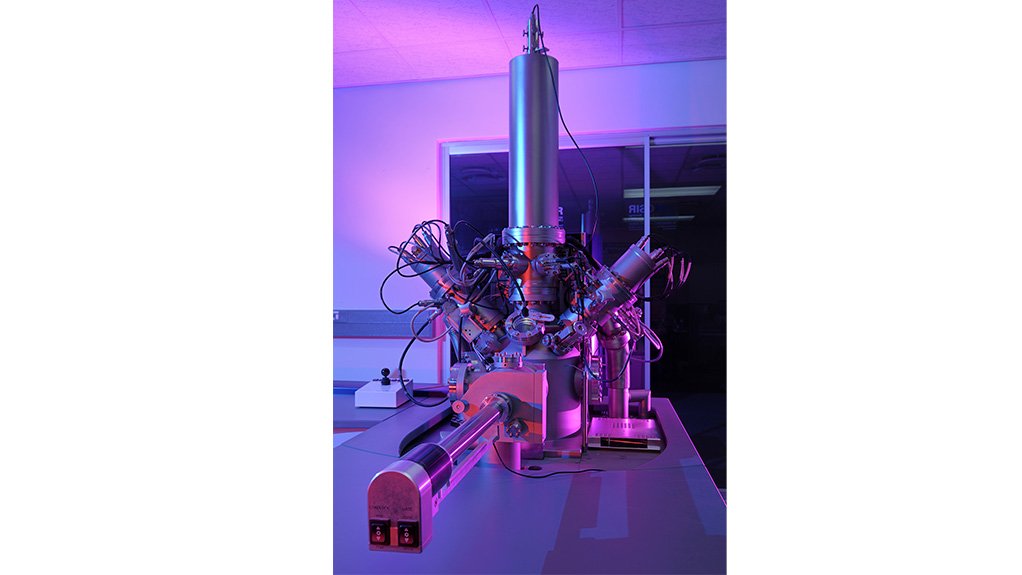

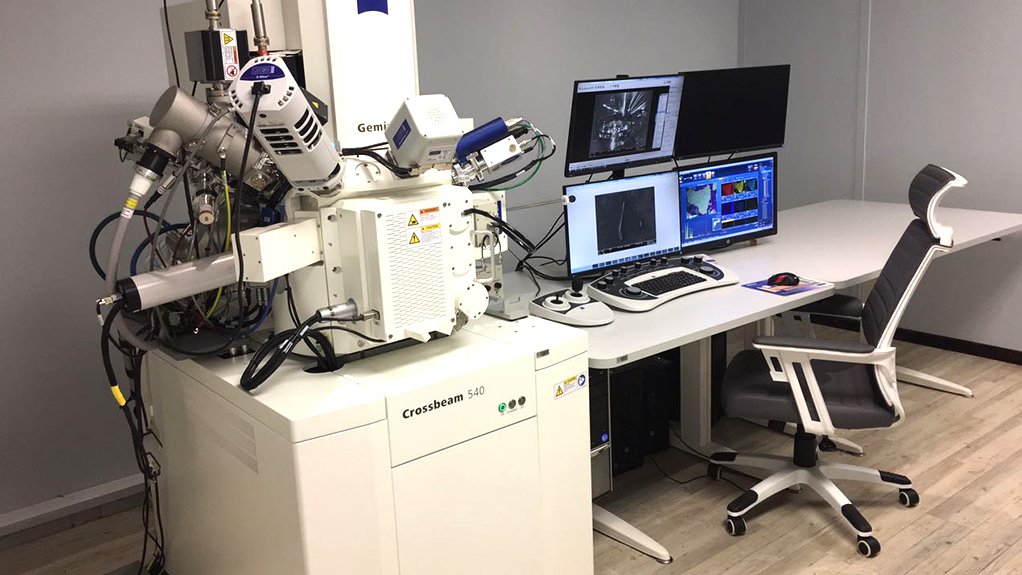

STATE OF ART NMISA’s measuring equipment ensures product quality, safety, and consistency across various sectors

The recent Manufacturing Indaba conference provided State-owned research body National Metrology Institute of South Africa (NMISA) with a platform to highlight the importance of accurate measurements in manufacturing, as well as to showcase its solutions and engage with customers.

As an exhibitor at the conference, which was held at the Sandton Convention Centre from October 24 to 26, NMISA showcased its Kibble Balance as well as the range of services it offers.

“The conference enabled us to promote our company’s offerings – we networked and also got leads of potential clients through the conference,” says NMISA manufacturing competitiveness programme manager Clive Oliphant.

He emphasises that the Manufacturing Indaba gave NMISA the opportunity to showcase the full value that the company offers to the manufacturing sector.

“NMISA plays a vital role within the manufacturing sector such that our measuring equipment is the best in South Africa and, in some cases, the best in the southern hemisphere,” says Oliphant.

He elaborates that the organisation’s measurement techniques provide the “confidence that all measurements made in South Africa are reliable and internationally recognised”, which potential customers were able to learn about directly from NMISA representatives at the Indaba.

Additionally, Oliphant adds that the conference was also an opportunity for NMISA to identify measurement needs within the manufacturing space and meet such needs through innovative measurement solutions.

Pushing Innovation

NMISA is involved in the development and adoption of innovative technologies, such as additive manufacturing, in South Africa. The institute is conducting research, providing technical expertise, and promoting collaboration with industry and government stakeholders.

Additionally, NMISA provides calibration, materials characterisation services and training to ensure the accuracy and quality of three-dimensional printing processes.

“For the last few decades NMISA has been developing and providing measurement solutions for the development of additive manufacturing in South Africa, as one of its focus areas” says Oliphant.

A key component of the institute’s involvement in standard development is to ensure that South African industries align with global best practices in emerging technologies while also fostering quality and precision in manufacturing, Oliphant explains.

Discussing the value of additive manufacturing, he says that from a metrology viewpoint, additive manufacturing provides the advantage of producing precise and accurate measurement tools and calibration equipment, tailored to specific metrology needs.

However, despite the numerous benefits of additive manufacturing, Oliphant explains that widespread adoption faces various challenges. These include the associated high costs, lack of skills and training, regulatory issues and technology access.

NMISA is addressing these barriers through its work in additive industry development, Oliphant explains. He adds that NMISA aims to ensure that additive manufacturing can be embraced by a broader range of manufacturers and industries while meeting quality standards and regulatory requirements.

Meeting International Standards

NMISA’s “state-of-the-art” measuring equipment ensures product quality, safety, and consistency across various sectors, including automotive, food packaging, and metalwork. These precision measurements enhance efficiency and competitiveness, ultimately saving costs for manufacturers by reducing errors, optimising processes and minimising defects and waste.

NMISA maintains the international equivalence of South Africa's National Measurement Standards (NMS) through collaborations with local and international organisations, participating in global comparisons, and implementing quality control measures. By doing so, they ensure that South Africa's NMS remain accurate and up-to-date, supporting precise measurements and alignment with international standards.

Oliphant highlights that, for South African manufacturers aiming to enter international markets, adherence to industry-specific standards and certifications is crucial.

In particular, manufacturers need to comply with International Organisation for Standardisation standards for quality and environmental management, as well as certifications or markings for European Union and North American requirements. Such compliance is essential to ensure product quality, safety, and market access on a global scale, he elaborates.

Additionally, Oliphant notes the importance of implementing traceability for international product supply. He explains that through implementing traceability, manufacturers can benefit from improved product quality, safety, market access, supply chain efficiency, and enhanced consumer trust, which are essential for success in the global market.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation