New labyrinth seals avoid galling and failures

This article has been supplied.

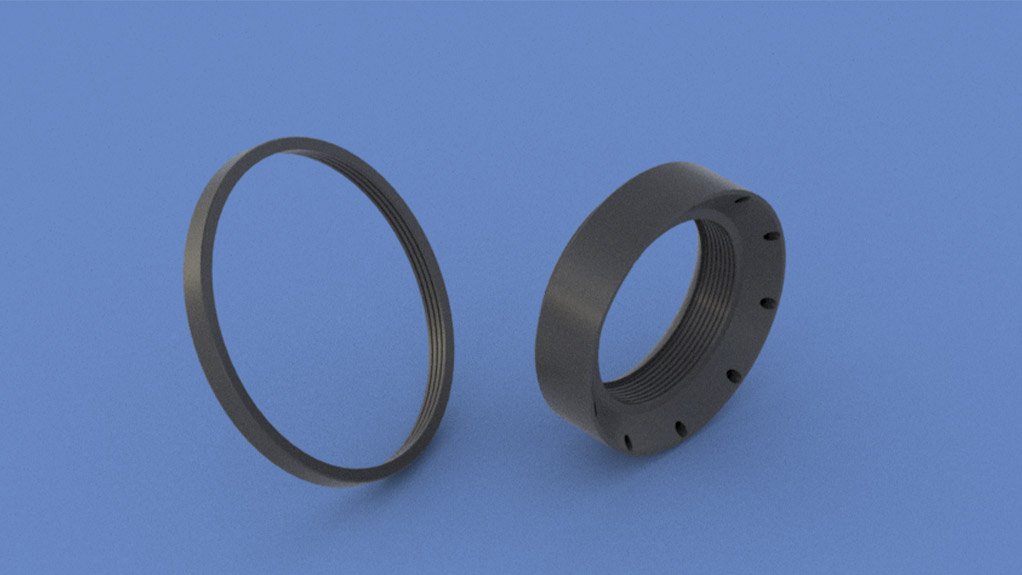

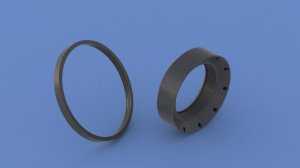

Labyrinth seals can now be ordered from Vesconite Bearings using client specifications.

This follows the supply and successful use of Vesconite labyrinth seals by several large pump original equipment manufacturers in multiple labyrinth seal designs over the past 10 years.

Labyrinth seals are mechanical seals that provide a long path for water to flow through to prevent leakage. As the name suggests, these seals may be composed of a large number of grooves acting as labyrinth chambers. The labyrinths help reduce the leakage flow through the seals.

Vesconite bearing materials have proved valuable in these seals as they are self lubricating. As a result, during shaft rotation, when parts of the seal come in contact with the shaft, high temperatures and even galling are avoided. This is unlike traditional stainless steel and bronze labyrinth seals, where contact leads to high frictional forces, rapid increases in contact temperatures, galling and even catastrophic pump failures.

Vesconite labyrinth seals can also be designed to optimise their performance. Since there is no threat of galling, close clearances can be applied. This is important since the smaller the clearance, the lower the flow of water past the seal and the higher the efficiency of the pump.

Vesconite bearing materials offer the advantage of being more economical than their stainless steel counterparts, and much quicker to machine.

Vesconite can be machined easily to produce complicated grooves for water limiting flow and for securing the seal, and have completely replaced stainless steel parts in many pump applications.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation