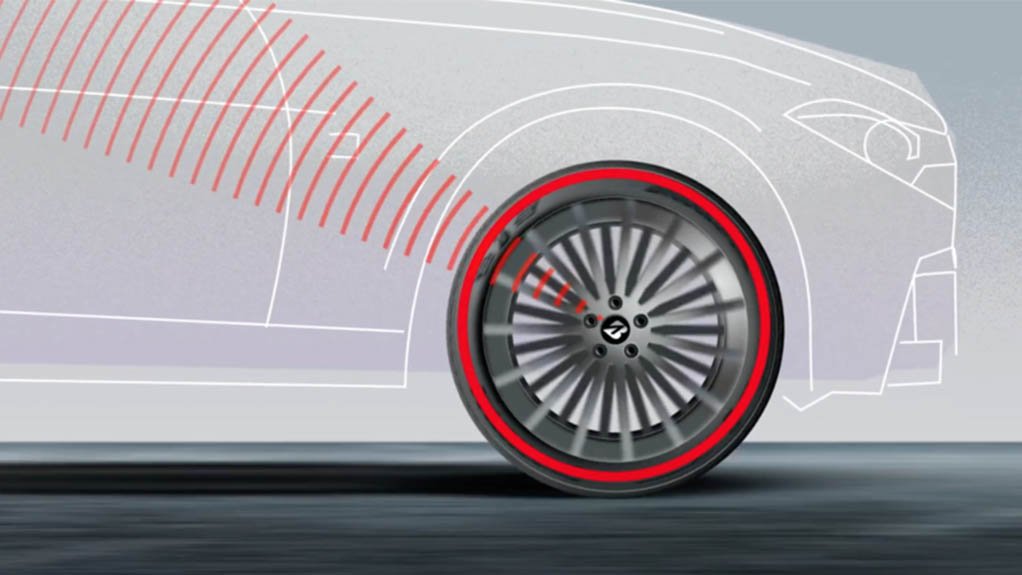

New real-time monitoring system enhances safety

DAMAGE CONTROL The Tyre Damage Monitoring System uses algorithms to detect and predict failures before they become catastrophic

Automotive and truck parts manufacturer Bridgestone in collaboration with technology company Microsoft has developed a unique and innovative monitoring system to detect tyre damage issues in real-time.

Bridgestone Europe, Russia, Middle East, India and Africa (EMIA) CEO and president Laurent Dartoux says damaged tyres can either directly lead to accidents or adversely affect other components of a vehicle which could result in an accident.

According to the Global Auto Tyre Market 2018 report published by market research firm Global Marketers, in September 2018, 30% of all accidents are caused by technical failure.

Dartoux adds that most common tyre problems such as incorrect inflation and wear and tear can be avoided with regular checks and maintenance.

However, when it comes to the more serious issue where a tyre has been damaged to the extent that it can lead to a car accident, this can only be detected by close manual inspection.

The Tyre Damage Monitoring System uses algorithms to detect events affecting a tyre’s surface and carcass with the use of Microsoft’s Connected Vehicle Platform (MCVP) cloud framework technology.

The driver is immediately alerted of the hazard and is then able to react to avoid potential danger. The MCVP uses existing sensor data without the need to install extra hardware.

With a system that not only understands when damage occurred, but also where, Bridgestone’s Tyre Damage Monitoring System provides broader insight into road conditions and infrastructure.

The information can be used to alert road agencies, specifically those dealing with road damage related issues, about the whereabouts of potholes and other road hazards.

Microsoft’s platform will also provide a digital infrastructure that delivers connected mobility solutions with access to Microsoft Azure cloud, artificial intelligence, and Internet of Things capabilities.

The new Tyre Damage Monitoring System is currently available to all vehicle fleets and original-equipment manufacturers (OEMs) that use MCVP. This partnership with Microsoft means that Bridgestone can also further develop solutions for fleets and key OEM partners globally.

The system aims to increase road safety and reduce accidents caused by technical failure.

This collaboration is the next step on Bridgestone’s journey to become a global leader in sustainable and advanced mobility solutions. In turn, working with Bridgestone helps Microsoft grow its ecosystem of supporting partners, and enables MCVP’s customers to integrate these partner solutions into their own offerings.

Dartoux adds that digital is such a huge part of what the company does today at Bridgestone, and it is imperative that it works with industry-leading partners who can support its needs today and in the future.

“By teaming up with Microsoft we have the opportunity to bring our Tyre Damage Monitoring System to millions of drivers.

”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation