Newly designed large-sealed bearings reduce grease consumption

Newly designed large bearings from SKF have been shown to reduce grease consumption in the bearing by up to 99% and last up to twice as long as conventional open bearings, helping to extend service life and cut costs.

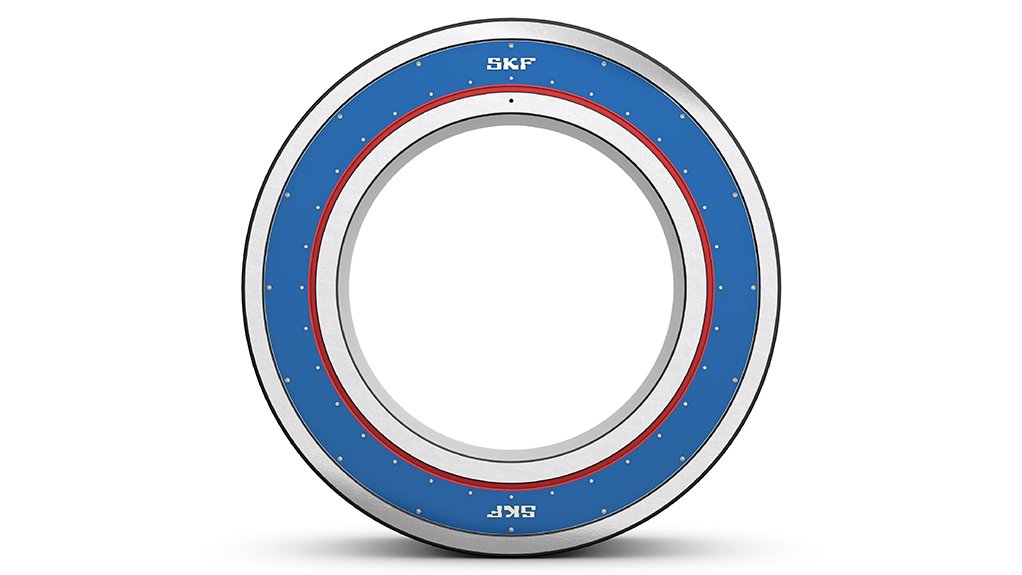

The company has extended its range of large bearings for roller presses to include a new version that is sealed on both sides. Its Explorer spherical roller bearings (SRBs) in the 241 series are now available up to 1250 mm bore. The series and sizes are commonly used in high-pressure grinding rolls (HPGRs) in cement and mining industries.

“Using sealed bearings is the best way to increase mean time between failures,” says SKF product line manager for sealed SRBs Daniel Ortega. “It is a long-term investment that increases machine availability and reliability.

The sealed SRBs require only 7 kg of grease, compared to 540 kg of grease normally required over the same time interval for a high-pressure grinding roll in which four large spherical roller bearings are used. This helps to reduce both costs and environmental impact.

In addition, the sealed SRB can be remanufactured twice, further extending service life, raising productivity and machine availability, while also lowering total cost of ownership.

The new bearing has been redesigned to have a higher load-carrying capacity. Bearings with a bore-diameter below 1 000 mm have a hydrogenating acrylonitrile butadiene rubber, or HNBR, seal that is retained by a snap ring. Larger bearings use a G-ECOPUR seal that is bolted to the bearing’s outer ring.

The sealed bearing can be used on its own, or as part of an SKF three-barrier solution. Typical end-use applications include the mining, mineral processing and cement industries.

Roller press bearings often wear out because ineffective sealing leads to lubricant contamination. The sealed bearings overcome this problem and production does not need to be stopped for preventive maintenance of the bearing, as the wear of the roller press roller determines when a service is needed.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation