Next-gen planetary gearboxes

Planetary gearboxes have advanced in size, weight and application versatility and SEW-EURODRIVE notes that its locally engineered high performance solutions are extending its reach across a growing range of industries, while also ensuring faster lead times.

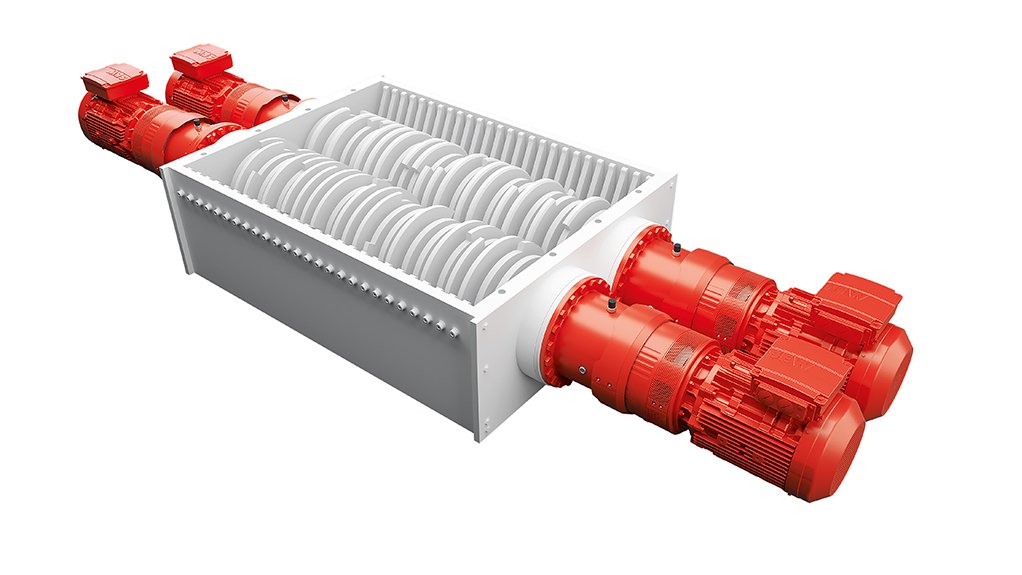

SEW-EURODRIVE business development representative Nick McKey explains that planetary gear units are suited to applications demanding low speeds and high torque, and that the company has tailored its solutions to meet the needs of heavy-duty sectors such as sugar and mining as well as industries including automotive and food processing.

“Our SEW P2.e planetary units, for example, are the first in their class to feature a planetary head directly coupled to an electric motor,” McKey says. “This design maximises one of their key advantages - a compact footprint and reduced weight - making them easy to integrate into a wide range of applications.”

Their smaller size and lighter weight allow these planetary gear units to be installed in tight spaces and overhung applications, while also simplifying installation and lowering costs.

“Planetary gears already achieve an impressive 96% to 98% efficiency and by pairing them with our IE3 motors we help customers further reduce power consumption and operating costs,” explains McKey.

The company describes how it has boosted the efficiency and longevity of its geared motors and industrial gearboxes through the use of its specialised gear oil, which is used across all its gearboxes, enabling them to run at cooler temperatures, which helps to improve efficiency and extend service life.

McKey notes that SEW-EURODRIVE’s planetary gear units are designed for easy installation, offering multiple interface options such as torque arms or flange mounting whether vertically, horizontally, or at various pivoting angles.

McKey underscores the company’s focus on project planning and engineering to ensure each planetary gearbox is precisely matched to the customer’s application in terms of size and torque.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation