Opportunities, challenges in local value chain for solar, wind energy

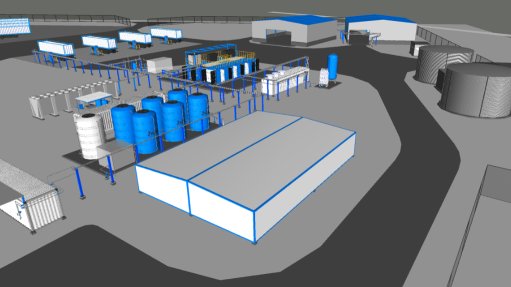

Two new reports published by Trade and Industrial Policies Strategies (TIPS), relating to solar and wind energy respectively, point out that electricity market reform is likely to drive an increase in solar and wind energy projects across the country, which will, in turn, increase demand for components and services in these industries.

For solar, the report – ‘Insights into the solar photovoltaic (PV) manufacturing value chain in South Africa’ – indicates the critical need for reliable and sustained demand, as well as policy certainty, in the solar PV space.

Currently, there are relatively few local firms involved in manufacturing solar PV components and these firms require further industrial development support to grow and expand employment, the report emphasises.

It highlights that, in particular, for inverters, the feasibility of an investment into a laboratory that can provide European Union (EU) standards certification should be assessed. Imported smaller inverters for the local small-scale embedded generation (SSEG) market should also be tested against South African electricity quality.

This would support manufacturers of both large and small inverters to compete with imported products, the report avers.

The report notes that developing improved professionalisation of installers is an important focus area. It points out that PV GreenCard is doing work to professionalise installers, but that more can be done.

For small rooftop solar PV consumers, the landscape is difficult to understand and price differentials between suppliers are significant. More can be done to upskill, professionalise and support this rapidly growing part of the solar PV SSEG market, the reports show.

It also says that access to concessional finance should be provided to support the growth of local small engineering businesses that manufacture inverters and are already well established, as well as the export of those products to the rest of the continent and globally.

Training programmes are required to create skills to take advantage of employment opportunities for technicians, electricians, and similar for inverter manufacturing, assembly, installation, servicing and repair, the report outlines.

It adds that, for utility-scale installations, with capital-intensive technology, the correct skills levels are essential to responsibly and safely operate the specialised equipment.

The report posits that the dominance in the market of imported goods challenges local firms, and that measures to manage imports and support local suppliers should be carefully considered.

The report states that the locally manufactured steel and aluminium inputs for customised mounting structures are not cheaper in South Africa than imports, as the import parity pricing works against the use of local billets in mounting structures and frames.

Therefore, for manufacturing to use local billets, the lack of price competitiveness and limited capabilities needs to be addressed.

The report also notes that an initiative to deal with solar PV componentry waste is required.

With regard to import replacement potential, there is an opportunity to grow local manufacturing capabilities in “photosensitive semiconductor devices” (PV modules) and “static converters” (inverters) as these are the two largest categories in value of imported solar PV characteristic goods, the report outlines.

It emphasises that local demand from existing and prospective manufacturers should be supported adequately.

For manufacturers supplying private solar PV projects that are outside of the Renewable Energy Independent Power Producer Procurement Programme (REIPPPP), there appears to be considerable opportunity for expansion, not just in South Africa but also into the rest of the continent, the report says.

However, concurrently, the International Energy Agency has noted the difficulty in forecasting beyond 2023 – solar PV is facing higher investment costs as a result of elevated commodity prices resulting from Russia’s Ukraine invasion; complications and delays with power purchase agreements especially in the EU; and rising interest rates are raising costs of capital for renewable developers.

Therefore, plans for future solar energy manufacturing in South Africa will need to consider global shifts and future volatility in global renewable energy markets in addition to local conditions and industry potential.

WIND

Another report from TIPS – ‘Insights into the Wind Energy value chain in South Africa’ – indicates that wind energy does not have a small-scale embedded market, so the potential for rapid offtake relates to the REIPPPP and large private projects.

However, despite this possible rapid growth in demand for components, there are currently relatively few local firms involved in manufacturing for wind energy, it notes.

Therefore, the local firms participating in manufacturing componentry require further industrial development support to grow and expand employment.

In particular, fixing the impediments to local manufacturing for utility-scale (and highly competitive and technology-dependent) projects will require measures to address barriers, including the lack of local competitively priced input materials.

Further considerations to improve the opportunities for growth in local manufacturing of components for wind energy include that participation in the REIPPPP for local manufacturers is challenged by the conditionality, financial guarantees, original-equipment manufacturer (OEM) requirements and relationships, and long lead times in the delivery of projects, among other factors.

This make supplying to the REIPPPP difficult for small firms despite local designation regulations. There accordingly exists an opportunity to configure industrial support and address the REIPPPP design to better support local manufacturers. This may include improved access to carefully structured concessional finance, the report outlines.

In terms of tower manufacturing, local precast concrete is noted to be at a distinct advantage over steel towers. The development of toll manufacturing facilities that could produce for several OEMs is an opportunity that could be further explored, the report proffers.

For the local manufacturing of tower internals, like ladders, the correct specifications of aluminium and steel need to be extruded locally. Opportunities need to be explored to produce both the correct steel and aluminium products in South Africa.

While there may be an opportunity to assemble nacelles locally, moving beyond assembly into the manufacture of nacelle parts and blades will take an investment in skills, capabilities and partnerships with leading OEMs, the report indicates.

Other manufactured products which are not unique to renewables industries, like fasteners, for example, should also be locally sourced, the report says.

The report also notes a need to upskill and professionalise local staff to fulfil technical roles in the value chain. This may require special training and accreditation, and the pairing of foreign skills with local graduates or staff for on-the-job training.

An initiative to deal with wind energy componentry waste should be investigated, the report suggests.

It says that this could address opportunities for the reuse and recycling of the blades and other parts as well as the extraction of critical materials.

All measures considered to support local industry participation must be appropriately aligned to industry conditions and potential and, with that, decent work creation, the report emphasises.

As with solar, South African players must also consider international and local factors.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation