Our innovations are the key partnership to your future

EIE Group Chief Executive Officer Gary Neubert

National Technical & Training Specialist Gordon Symons

Photo by Christo Greyling

Louis Fourie, National Product Specialist for Warehousing Equipment

Photo by Christo Greyling

Stephen Mostert, National Technical Specialist at Toyota Forklift

Photo by Christo Greyling

Tony Saincic, HAKO Operations Manager

“The EIE Group is known for its innovative state-of-the-art machinery and associated technologies on their automated and semi-automated solutions. Similarly, our reputation for applying solutions that ensure that our customer’s operations are fully optimised and fully supported through our customer relationship management systems makes it a win-win relationship” said EIE Group Chief Executive Officer Gary Neubert.

“The constant evolution of information technology and how it can be successfully and effectively applied across our industry is exciting and often ground breaking. In order to remain competitive, we believe we have to do things differently by using technology that will benefit our customers as well as improve our processes. At EIE we don’t play catch-up, we play at the very forefront. That is why we are the partner of choice

for distribution, rental, sales and value-added services in the industrial equipment market where we offer a total solution, provide best-in-class brands and deliver optimal life-time value for our customers”.

“We believe our differentiator is in our aftersales service. It is this that makes us the preferred supplier. If we can optimise your fleet of 18 forklift trucks, there is no need for you to find additional forklift Capex” he said.

About EIE

The EIE Group has exclusive distribution rights in Southern Africa for Toyota Forklift, BT Warehousing equipment, Flexi Narrow Aisle forklifts, Konecranes (SMV) heavy duty forklifts and container handling equipment, Terberg terminal tractors, Hawker batteries and chargers and Hako industrial cleaning equipment.

EIE offers long and short-term rentals, service and maintenance contracts, sales of new and used equipment and parts, fleet management, operator driver training, load testing and battery bay management.

The group has a presence in the four main regions in South Africa, maintains 10 branches and several dealerships in Southern Africa with representation in Angola, Botswana, Mozambique, Malawi, Madagascar, Mauritius, Namibia, Swaziland, Tanzania, Zambia and Zimbabwe.

The well-known 600SA brand also forms part of the EIE Group and offers lifting and loading, cleansing and waste and lifting at height equipment.

The UK industrial equipment business Impact Handling, is the exclusive distributor for Cat Lift Trucks and Konecranes and has a vast network of depots around the UK and Ireland.

The Future of Automation and Use of Technology in Business

“As leaders in the market we need to be the pioneers and keep with the times by always innovating and implementing new things. They might not initially work out as we thought, but we will continue to innovate and learn from mistakes” said Managing Director of Toyota Industrial Equipment (TIE), Shumani Tshifularo.

“We are an entrepreneurial culture business and encourage our employees to come up with new ideas and to develop new things. We are aware that future applications with respect to industrial equipment is all about using high tech and automation – streamlining processes and keeping downtime to an absolute minimum, so we need to embrace it but knowing we can only do it with the support of the good people that we have in our business” he said.

TIE has embarked upon achieving a 40% market share for Toyota Forklift which they believe is achievable through innovation and a forward-thinking way of conducting business. Tshifularo added “Customers are looking for more than a forklift. They want to rely on us for their materials handling and equipment solutions since we are part of their team”.

“Our biggest differentiator as a business is our openness to technological advancement, which we need to do to be in business. However, our relationships with our customers comes first, and our OEMs is also a very crucial relationship. These factors will never change. It is how we marry the two (technology and people) successfully that makes us the successful organisation we are today – continuously looking to give our customer the best service and support” said Tshifularo.

Our People

“EIE would not be the market leader that it is without our people” Neubert said. “Every branch and division within EIE has a team that is dedicated to providing service excellence through the application of new methodologies and technologies. These innovations enhance our customer’s experience not only of what we offer but how we deliver and conduct our servicing. Our philosophy is to ensure that every employee, no matter the level, has the opportunity to reach their potential and thereby contribute to the success of EIE”.

“The fact that we have a high number of women participating at executive and managerial levels throughout EIE is something to be proud of, some 33.3% of our top, senior and middle management positions are occupied by women” commented Neubert.

The company has three levels of leadership training: personal mastery, emerging leadership and leadership development. The training is customised to the needs of the EIE Group.

EIE invests heavily in training and engages with various Universities of Technology in South Africa to offer opportunities for graduate engineers to complete the practical side of their degree at EIE. “We encourage young engineers to present on how we can improve elements of our offering in the future. For example, would the use of drones be a practical way forward for the delivery of parts to our customers, we

don’t know yet, but we encourage thought and debate around various issues such

as this” said Neubert.

All EIE service technicians undergo Service Technician Education Programme (STEP) training.

Superior Intelligence

Toyota Forklift machinery in particular is a showcase for what can be achieved with new technology. The company has introduced the ‘Mobile Mechanic’ which now eliminates all the time delays previously associated with a service call: from analysing the fault, ordering the parts to invoicing. Four hundred Toyota Forklift field agents now use tablets for all their activities making the process paper free, reducing travel time as information is readily available for assessment, delivering spare parts directly to the technician. Customer sign off is electronically recorded and the job card relayed to the head office for processing.

Savings on labour, fuel and time costs enables Toyota Forklift to perform more efficiently and effectively, which has obvious benefits to its customer base when one looks at, for example, how the fuel price has escalated over the last 10 years.

“Increasing our automation and semi-automation systems is a gradual process that will feature in all of our new projects and developments. It is a big and exciting factor that gives us our competitive edge” commented Neubert.

Economic Upturn

“The economy has been in a downturn, there is no avoiding this fact. We at EIE have, over the last few years, streamlined our operations whilst ensuring that we have maintained our high standard of customer engagement and servicing. Our attention to providing customers with effective solutions is as a result of our own improved processes and best practice use of new technology” said Neubert.

“I believe that with the fresh political horizon that we are witnessing the anticipated economic upturn is not far around the corner. We are optimistic about the future of South Africa’s industries; we are optimistic about future foreign investment and engagement in our country. We are extremely excited about how automation and semi-automated systems can play a role within our processes in a positive way, that not only makes EIE more efficient, but makes our customer’s operations more effective and cost-efficient as well” Neubert said.

MD Tshifularo added “It is a tough economy out there and people do not have the time or money to waste anymore, which is why we factor speed, reliability and accuracy into our solutions by embracing technology and effective systems in order to serve the customer efficiently. There will be an upturn in the economy if we continue along a sound economic and political path – we are already on top of our game, from here we can only increase our market share further” he said.

Advanced Technologies Require Advanced Upskilling

“At Toyota Forklift we are at the cutting edge of technology. That is who we are and what we offer. However, we are not complacent, and our workforce has to be 110% up to speed with all of the latest in product and systems developments” commented Stephen Mostert, National Technical Specialist at Toyota Forklift. “This is why we implement a technical training programme that is rolled out nationally and continually updated. Systems change so rapidly in this era of high-technology and the use of Internet technology in industrial applications in particular has grown so exponentially that the adage ‘you lose if you snooze’ is never more applicable than right now. For our customer’s operations to benefit from new innovations our teams have to be at the forefront of this knowledge transfer” he said.

Long gone are the days of truck operators disembarking clutching wads of paper full of information to be logged in, or perhaps braking too much as the forklift travels through numerous packing aisles. Even the odd bump against a pallet or wall is no longer secret. Toyota Forklift offers a range of trucks which have state-of-the-art data logging, gps, semi-automation and online monitoring apps installed: the Toyota Forklift is no longer just a forklift, it is a lift truck with intelligence.

Mostert said “For example we are utilising over 2,500 I_Site mobile apps in South Africa which are continuously updated with machinery and environmental operational data that can be used for preventative maintenance planning, driver re-training scheduling and fleet optimisation review processes to name but a few scenarios”.

“The ‘Mobile Mechanic’ which is a roadside technician mobility app now utilised by our technicians is a fully integrated point of sale, workshop loading and incident management tool which connects back to Auto Line” said Mostert. The app is accessible via a Tablet or Laptop.

The app offers many practical innovations such as an offline mode where technicians can continue to clock without any internet signal. Once back within connectivity range the information is automatically updated. Google Maps is utilised to order in Incident Management and assist with location identification.

There is nothing that the technician cannot load up to or track via the ‘Mobile Mechanic’ app: access to stock, unknown parts can be added and ordered, labour lines for repair orders, clocking from remote locations, pre-defined service sheets available, records of inspections and defects, photographs of damaged parts with details written back to Work in Progress (WIP) reports, travel status of the technician and signature capture on completion via mobile device by end user and the technician.

“This obviously affords the Service Manager crucial information such as technician visibility and current status and daily activity reviews. The WIP is updated immediately after completion. The benefit of the ‘Mobile Mechanic’ app is that it is a device which operates in real time. It enables jobs to be tracked and improves cash flows for businesses said Mostert.

“All of our improved technological offerings comply with health and safety regulations. Our technicians are fully on board with the constant need to innovate. Obviously with new systems come new design requirements. With our forklift trucks now being programmed in warehouse activity layouts and specific aisle performance and restrictions, comes the need for new warehouse design to accommodate the fleet operations properly and safely” Mostert added. “We at Toyota Forklift have contributed enormously to new warehouse design requirements throughout South Africa in order for automated fleet management to be cost-effectively and efficiently implemented”.

Investing in Training

“Over the years the role of the technician has changed dramatically. Technicians today have their work cut out for them keeping abreast of the latest technologies and being able to successfully implement them” said National Technical & Training Specialist Gordon Symons.

Toyota Forklift invests heavily in training throughout the group. Their current ‘Back 2 Basics’ drive focuses on closing skills gaps identified before technicians attend more advanced skills programmes. Specific objectives of technical training include:

- Apprenticeships / Learnerships and artisan recognition of prior learning (ARPL)

- OEM specific training and product specific training

- Various skills programmes that offers credits towards a registered qualification

Toyota STEP is our OEM specific technician education programme for the Toyota brand which focuses on developing Master Technicians within the group.

“95% of our technicians have completed the STEP 1 (Qualified) qualification, with 25% and 8% having completed STEP 2 (Expert) and 3 (Master) respectively” said Symons.

“There is a greater understanding of the positive role that technology and advanced systems play in our industry by our technicians and related specialists. There has been a major shift in the mindset within our industry and our people are keen to keep abreast, be upskilled and be re-trained where required. It is this positivity that drives our technicians to succeed and to pass their expertise on to our customer, showing how their operations can benefit from innovative and updated processes” Symons said.

“For example, our recently launched Rapid Response app for forklift fault logging eliminates customer downtime. Previously, customers have to call into our controller and wait. Now the customer can easily and quickly log their fault knowing that our technicians will be able to assist more efficiently to the fault logged. The customer can track our progress in this regard. So, the investment in app and software training doesn’t trickle down it flows quickly down and increases efficiencies to the benefit of our customers” said Symons.

Aftersales Services Evaluation and Certification (ASEC)

The EIE Group subscribes to the Kaizen Approach in its Parts and Service operation. This Japanese philosophy strives for continued improvement in all aspects of business. It is known as a methodology for continuous improvement, is a long-term approach to work that systematically seeks to achieve small, incremental changes in processes in order to improve efficiency and quality. The 5S concept associated with Kaizen is simply applied: sort, set in order, shine, standardise and sustain. The implementation of this approach has seen the group improve its levels of productivity, efficiency and quality levels dramatically.

EIE Superior Quality Offerings

HAKO Industrial Cleaners and Sweepers

HAKO industrial cleaning equipment from Germany is known for offering quality products for floor cleaning and ground maintenance since 1946. They have a wide spread of machinery from sweepers, vacuum-sweepers, scrubber-driers and a variety of walk-behind and ride-on machines and associated solutions.

“Since joining the EIE Group some eight years ago, HAKO Cleaning Equipment has increased its market share up to 15% and whereas before we were an ancillary service to Toyota Forklift customers, we have now expanded our footprint to include other sectors that utilise industrial cleaners and road sweepers” said Tony Saincic, HAKO Operations Manager.

“Our machines are suited for municipal applications, warehousing, retail centres, port and harbours, parking lots, petro forecourts, distribution centres, power stations and the hospitality sector. Our City Master Range is a road sweeping machine that has been used by municipalities globally, it is reliable, efficient and easy to maintain and can be powered by battery, diesel, petrol or LPG”.

Full operator training is provided and the machines are supported with maintenance agreements. Unlike other industrial cleaning machines, HAKO machines are simple to operate and offer the customer an optional onboard fleet management system to assess usage settings, battery life, problem solving data and fuel usage all easily accessible via a laptop.

HAKO recently launched the Hi-ONE, a compact scrubber-drier with an ability to carry out standardised cleaning processes independently, which has been made possible through a newly developed drive technology, special sensors and Hako’s in-house-developed navigation software. A strong emphasis was put on safety aspects. The machine is user-friendly in operation and programming of the autonomous cleaning machine, is possible by means of a smartphone app.

“If it needs to be cleaned or swept, then we have the appropriate machine to meet the requirement. It is currently the largest selling industrial cleaning machine in Europe. They embrace environmental needs through innovative energy savings; cutting water and detergent use by 50%; they are future-proofed and emission free due to 99.9% of particles being removed from exhaust emissions; offers less pollution; eliminates dust pollution by 99%; from conceptualisation to disposal they last longer and are disposed of in an eco-friendly manner”.

The HAKO range has the EIE Group technical and service support and we offer a one-year warranty. Feedback from customers has been extremely positive due to the machine’s longer lifespan and good performance. “The global demand for HAKO industrial cleaners is huge: as they are manufactured they are shipped out to meet orders – that speaks volumes” said Saincic.

Advanced Battery Power from Enersys

The changing face of the battery industry over the years has managed to eliminate previously problematic issues. One of the companies who have invested heavily into research and development of battery power is Enersys whose stringent testing has resulted in a range of safer, more effective batteries that enhance a customer’s fleet operation.

The Enersys range of batteries (aka as Hawker) can be used in every industrial truck solution from simple applications with a low capacity up to heavy duty multi-shift work.

The Perfect Plus standard battery is a low maintenance lead acid battery which offers a long life due to higher amp hours. Aside from forklift activities it is also suited to back-up power operations, solar systems and power for cell phone towers.

The introduction of lithium ion batteries into the Enersys range has meant that operators can expect a faster charging time thereby reducing battery change requirements coupled with reduced power costs and a greater lifespan.

The Enersys NexSys battery utilises the highly trusted Thin Plate Pure Lead (TPPL) technology and is offered in a standard and a fast charging configuration for us in a wider range of applications. Advanced system matching with NexSys and NexSys+ modular chargers offer a high performance with energy cost savings. NexSys batteries can be used across a range of vehicles that includes lift trucks, order pickers, pallet trucks, AGV/LGVs and cleaning machines.

The NexSys offers optimised charging compared to normal lead acid batteries giving the customer serious energy cost savings. They have a 160% utilisation cycle, and the battery can be charged in any location with no water required for the battery. Eliminating the need for expensive industrial battery bays to be built, the NexSys is a sealed unit suitable for areas where emissions have to be strictly monitored such as pharmaceutical, food and retail environments.

Demonstrations of the advanced NexSys battery will be rolled out initially in Gauteng and then nationally across South Africa during the second half of 2018.

The Enersys range of batteries has full technical support as well as service and maintenance agreements offered.

Lean thinking in the material handling environment

“Toyota Forklift's lean thinking approach is focussed on the optimisation of the material handling process through the application of Toyota Production System principles. Successful implementation of lean manufacturing principles such as Just in Time (JIT) and Autonomation (Jidoka) results in a smoother workflow, reduced costs and increased productivity within our organisation and within our customers operations.” says Louis Fourie, National Product Specialist for Warehousing Equipment.

Toyota Forklift's approach to new product development is rooted in lean thinking and focused on the trends and technologies that will contribute to making industry 4.0 a reality.

During the CeMAT convention in Hannover, it was announced that all electric warehousing trucks will be supplied with integrated telematics based on our market-leading I_Site technology. Data collected from the Toyota I_Site system shows that the adoption of best-practice, combined with the ability to monitor the way that equipment is operated, can substantially increase driver safety and utilisation while reducing repair and damage costs.

The integration of machine vision enables our OSE250 T-Mote order picking truck to stop or avoid obstacles while being remotely driven by the operator. The T-Mote seamlessly switches between manual and remote modes of operation depending on operator presence in the truck. This functionality reduces unnecessary activity by allowing the driver to remotely drive the truck forward when in dense picking areas, resulting in an increase in productivity of up to 20%. Controlled acceleration and braking results in reduced wear and tear and lower energy consumption.

Toyota Forklift has partnered with Microsoft to develop our T-One software platform to support our ever-growing fleet of automated guided vehicles (AGV’s). T-ONE is installed as an integration layer communicating with our AGVs and existing infrastructure such as warehouse management systems, goods identification and other material handling equipment. The intelligent software offers operational robustness and flexibility for easy scaling of operations and quick commissioning. T-ONE is at the heart of Toyota’s automated solutions integrating customer processes and providing a full overview and control of the material flow.

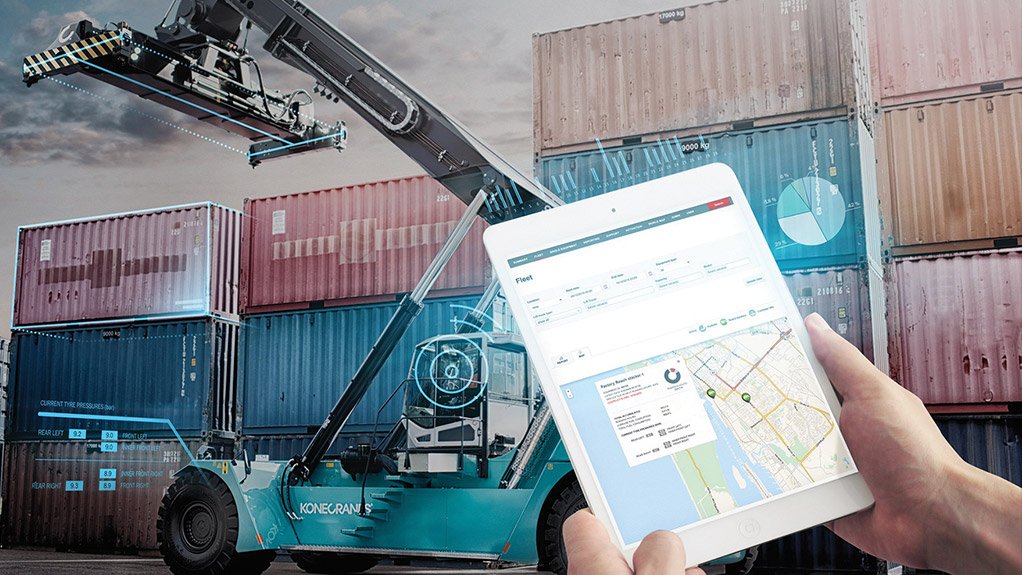

State-of-Art Technology Enhances the Konecranes Experience

Konecranes has introduced TRUCONNECT a remote monitoring and reporting service for lift trucks operating at ports and container depots. The device, an added option that can be retrofitted, provides an online view and periodic PDF reports that illustrate the actual use of the lift truck. It can be used as a tool for scheduling a lift trucks fleet maintenance actions and increasing the fleets uptime.

Drew McLean, National Technical Manager for Konecranes and Terberg, commented “There is always resistance to new technology and the change it brings initially, but once the customer can see the benefit of applying the technology to their operations the mindset is happily adjusted”.

“The TRUCONNECT monitoring is a system that will reap benefits for lift truck operations. The ability, via a laptop, to monitor one’s fleet efficiency, operational safety and plan maintenance management with more precision will optimise the machine and the operators performance”.

Benefits from the utilisation of the TRUCONNECT tracking device include:

- Safety alerts

- Machine status

- Average fuel consumption

- Average fuel consumption per lifted load

- Total fuel consumption

- Travelling distance

- Average travelling speed

- Load spectrum

- Total load lifted

- Engine coolant temperature

- Drop in engine oil pressure

- Transmission overheating

- Container lifting alarm

- Driving hours

- Next maintenance counter

“The ability to know exactly what your machine is doing and how it is doing it is important information for container operations. The cost of lift trucks is not cheap, and for example, to have a lift truck purchased to lift full container loads, performing on empty containers is not cost effective. The biggest financial outlay on lift trucks is fuel and tyres, savings of up to 10-15% can be achieved by data analysis from the device’s reports. All of this important data can be monitored with the TRUCONNECT device, optimising your operations and making them more cost-effective is a win as it will also eliminate inappropriate handling use and highlight where driver re-training could be required” said McLean.

Konecranes recently introduced the first hybrid reach stacker which offers innovative eco-efficient features that enhances performance, cuts fuel consumption, and reduces emissions.

The improved performance of the hybrid reach stacker has been made possible by electrifying all flows of energy in the lift truck. The reach stacker recovers the energy created from braking and lowering loads and stores it in the super capacitor for later use. A fuel-efficient diesel engine propels a generator, and basically provides needed electric energy to the energy storage. The energy storage in turn provides electric power to the electric drive motor as well as to the electrical motors that drive the hydraulic pumps. The electric motors can operate in generation mode, returning brake energy as well as load lowering energy through the hydraulic return flow back to the energy storage.

McLean said “The Hybrid reach stacker is a relatively new concept and has excellent maintenance, energy and environmental properties, It is a natural progression from our ‘traditional’ reach stackers which offer cost savings, a quality renowned and trusted globally, fuel savings, less noise, stability with a heavy duty box type chassis and strong four plate boxed lifting boom. The Konecranes range offers a suitable solution for every application they were designed to support, there is no doubt about their durability and longevity”.

The group also supplies a wide range of Terberg Terminal Tractors. Three principles are applied throughout the range: standardisation; KISS (keep it safe and simple) and reliability. All of the Terberg machines are engineered to meet the following important features: safety, visibility, performance, driver comfort and ease of maintenance.

A Proud Company

“I do firmly believe that the EIE Group and all its divisions make us a proud company. Our innovative technologies and how our people adapt and upskill constantly to provide excellent service to our customers is something to be proud of. That we constantly challenge the boundaries of technology is one of our key differentiators”.

“There is no challenge we cannot offer a solution for and there is no customer that is too big or too small for us to build a relationship with. We are not only in the industrial machinery business, we are in the people business” Neubert said.

“We have absolute belief in the effectiveness and reliability of what we offer. We are the market leaders in our fields of expertise. We are ahead of the game. We offer a superior quality product, we offer a personalised service. We stand by and live the ethics and values of the EIE Group, and we are proud of our service to the industry” concluded Neubert.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation