Precision in every drop - Powered by ICP Technology

This article has been supplied.

By: Sharista Raghunath – chemist, WearCheck

(Virtual Showroom) Accurate and reliable analytical data is essential for effective decision making in today’s competitive industrial landscape, especially in the condition monitoring arena, which focuses on predictive maintenance.

Elemental profiling using ICP-OES (Inductively Coupled Plasma – Optical Emission Spectroscopy) provides useful information on the chemical composition of lubricants. It can help track changes in specific additive profiles and contaminants that accumulate over time. Based on this data, it can be determined whether the oil remains suitable for use or if maintenance intervention is necessary. This Technical Bulletin highlights the principle, concept and methodology of WearCheck’s elemental analysis and how it is used to provide consistently reliable and accurate results.

ICP-OES: BASIC PRINCIPLES AND OPERATION

ICP-OES is a quantitative technique which involves measuring the light emitted by the elements present in lubricants (metals and non-metals) to determine their concentrations.

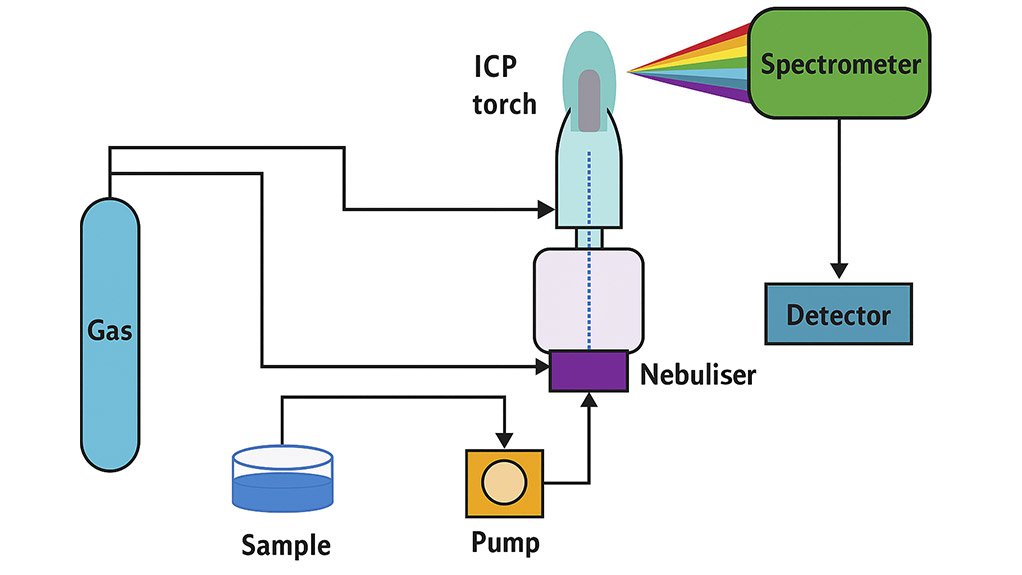

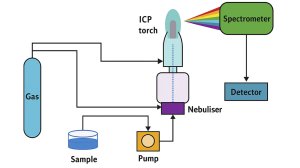

The process of operation involves sample introduction, atomisation, ionisation, excitation, emission, detection and quantification. The schematic of this process is outlined in Figure 1.

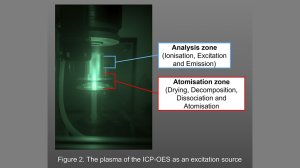

In the sample introduction stage, the diluted sample is pumped into a nebuliser to reduce the sample liquid into a fine mist (aerosol). The aerosol is introduced into a high-energy plasma excitation source – the ICP torch to decompose, dry and atomise the oil sample. Spontaneous emission of characteristic wavelengths of light occurs, which are then detected for quantification. A typical plasma is shown in Figure 2.

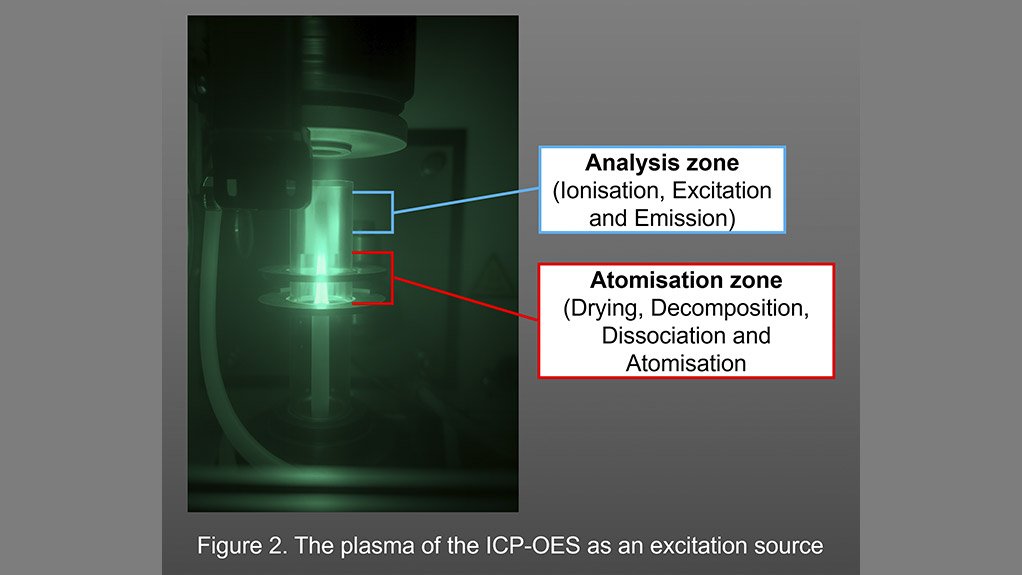

The plasma, a hot mixture of ionised argon gas, is fed and sustained by a constant flow of argon in an electromagnetic field. Although the plasma in Figure 2 appears green, it is actually brilliant white with bluish-violet overtones. A UV-protective screen, giving it its green colour, shields the operators from exposure to harmful rays from the plasma, similar to a welder’s mask.

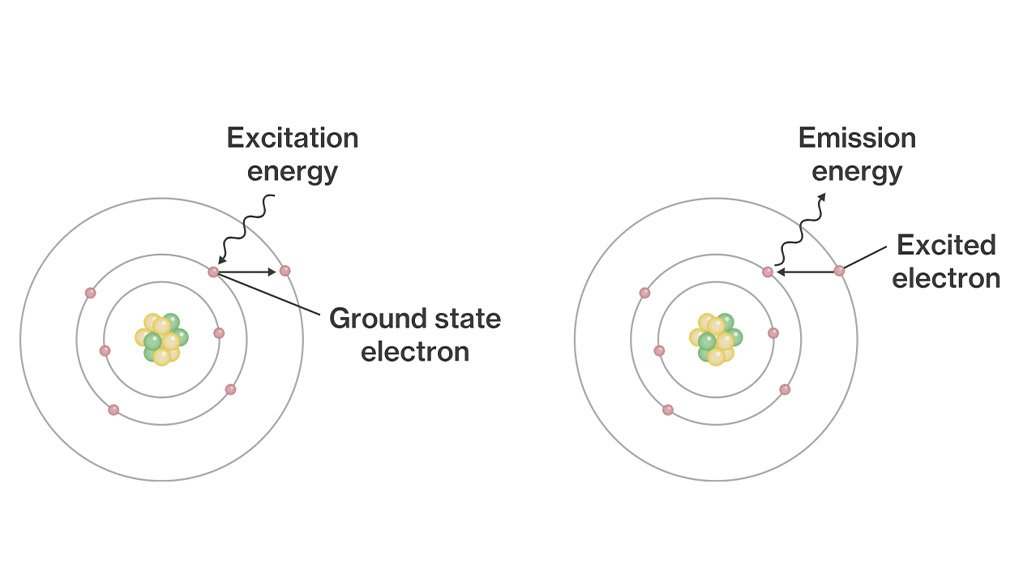

The sample aerosol flows into the atomisation zone where drying, decomposition and atomisation occur. These atoms then flow into the analytical zone where they are ionised (Figure 2) and excited as the electrons in the atoms absorb energy and reach a higher energy state.

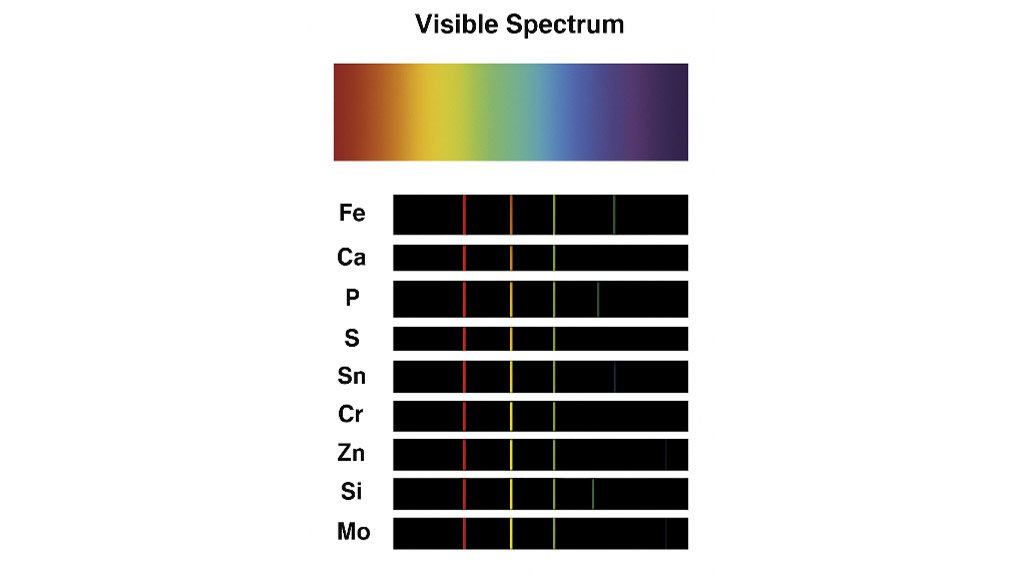

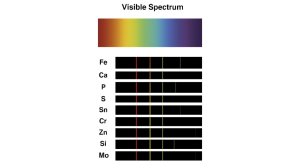

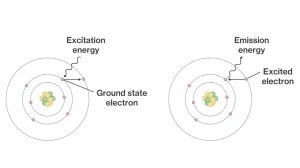

Naturally, this high-energy state cannot be sustained for long and the electron falls to its ground state, simultaneously releasing light (Figure 3). Each element will emit light of characteristic wavelengths in the ultraviolet and visible region of the electromagnetic spectrum. This phenomenon is analogous to the yellow glow produced when salt is sprinkled onto a braai or observed in sodium streetlights, as well as the blue-green emission observed when copper is introduced into a flame.

In this way, the amount of light detected for each wavelength can be traced back to its characteristic element and can be quantified. The higher the concentration of elements in the sample, the stronger the intensity of light that is emitted and the larger the ICP reading will be. The signal from the detector is processed into a result using calibration curves.

THE PRINCIPLE OF ICP DETECTION FOR QUANTIFICATION

Light emitted by the elements in the sample falls within the ultraviolet (UV) and visible parts of the electromagnetic spectrum. Figure 4 shows examples of elements measured at WearCheck, with their emission spectra in the visible range, where the coloured lines mark the characteristic wavelengths produced after excitation. For each element, we select one of these lines (a specific colour) for detection and quantification, choosing the wavelength that provides the best sensitivity and selectivity on the ICP-OES.

This emitted light is dispersive (spread-out), and a restrictor device - the polychromator - is used to allow a narrow band of the selected light to reach the detector. This device contains multiple slits to narrow the light into bands, and it has multiple detectors which allow for simultaneous detection and quantification.

WearCheck’s latest ICP models have the Echelle-based polychromator, which works on the same principle, and which enhances analytical stability and sensitivity, reduces sample consumption, and shortens analysis times per sample.

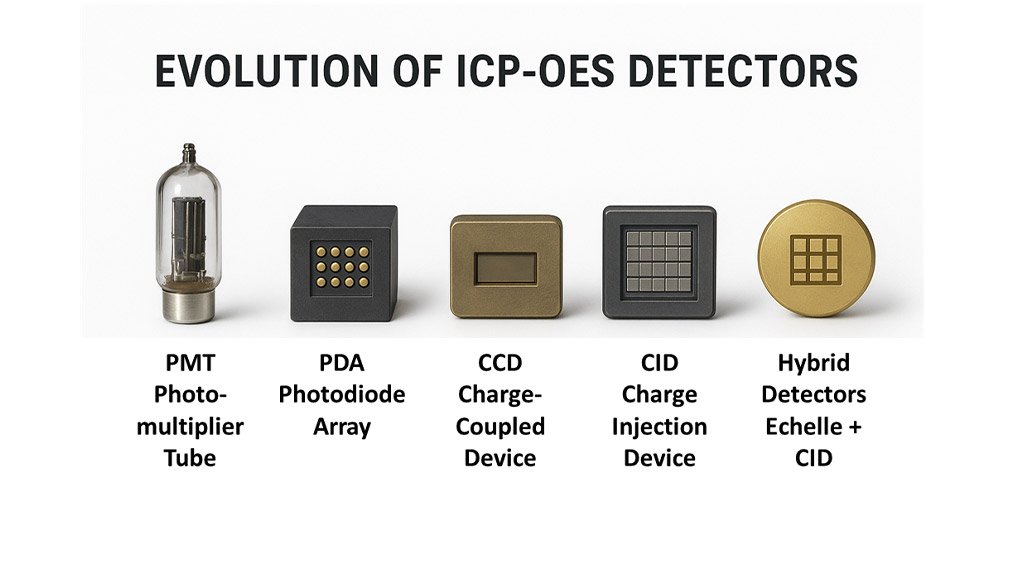

EVOLUTION OF DETECTION SYSTEMS IN ICP – A JOURNEY THROUGH THE HISTORY OF ADVANCING TECHNOLOGY

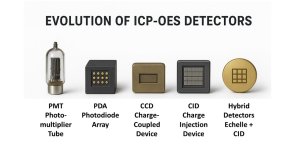

The detection system within the ICP plays a crucial role in the process of quantifying the elements. As the “eye” of the instrument, it needs to be reliable, sensitive, consistent and stable. The detection systems for ICP have evolved over the years (Figure 5).

Earlier systems, prevalent in the 1980s, used photomultiplier tubes (PMT), which applied the concept of converting emitted light from elements in the sample into a measurable signal by electron amplification using dynodes. As the photons of light hit the first dynode, electrons are released, which in turn hit the subsequent dynodes in the same manner. This eventually creates an amplified, measurable current, which is proportional to the quantity of element. This system exhibited excellent sensitivity and accuracy. The shortfalls were that it could only do one element at a time, and it incurred wear on internal moving parts, thereby shortening the lifespan of the detector and limiting its adequacy in handling complex samples.

In the 1990s, the photodiode array detectors (PDA) were introduced. This worked on the principle of a linear array of diodes that measured the emitted light of various wavelengths simultaneously. This step-up in technology led to higher sample throughput, faster analysis and greater detector stability.

Then came the charge-coupled devices (CCD) in the 2000s. These were 2D pixel arrays that stored electric charge proportional to light intensity, similar to digital camera sensors. They could detect a wide range of wavelengths simultaneously. Equipped with excellent accuracy, resolution and sensitivity, this solid-state detector meant longevity and reliable results.

The next generation of detectors was introduced in the 2010s. These were called the charge injection (CID) device detectors. These represented an advancement of the CCD, with random pixel access that allowed for re-use of pixels, which produced improved sensitivity and accuracy, robustness and stability at fluctuating temperatures. They could even tackle the most unfavourable oil sample. However, the downfall of these instruments was their slower data acquisition and the requirement of advanced software utilities.

The latest generation of detectors features the hybrid detector (Echelle + CCD/CID Arrays), which WearCheck currently employs. Hybrid detectors capture the entire spectrum of light emitted from the elements in the sample. They are equipped with highly integrated software capabilities and mathematical models to map all emission lines, and they correct and compensate for interferences with simultaneous quantification. With outstanding capabilities in accuracy, precision and linearity, these instruments help WearCheck to provide a top-notch ICP service.

CALIBRATION CURVE FOR QUANTIFICATION

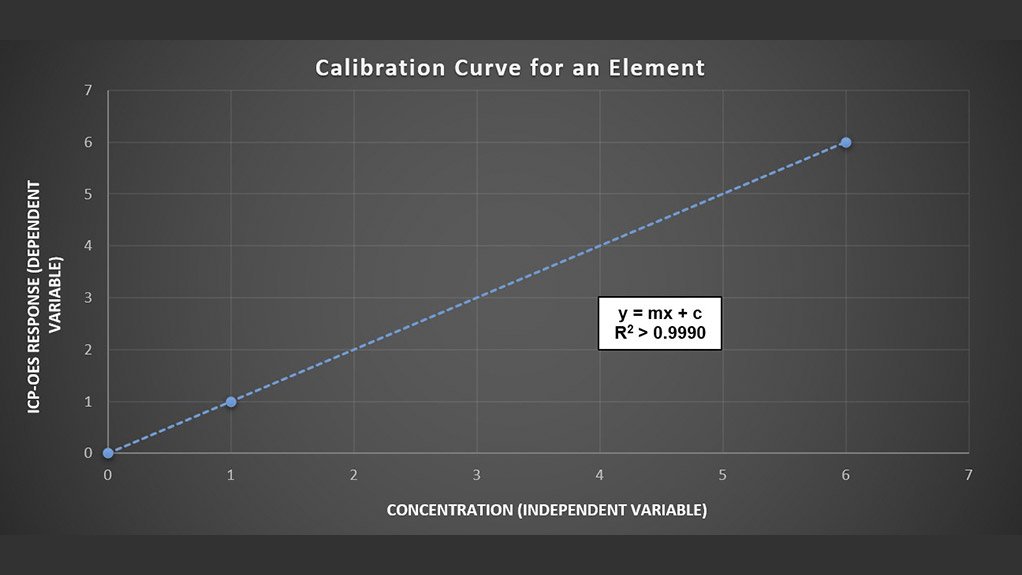

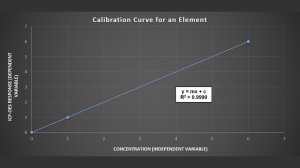

A calibration curve is a graphical representation of the linear relationship between the amount of element in the oil sample (independent variable) and the response from the ICP detector (dependent variable)3. This relationship is directly proportional, meaning that as the concentration of an element in the sample increases, the response from the detector also increases. A typical calibration curve is shown in Figure 6. A calibration curve is generated for each element after the calibration process.

The concentration of the elements in the oil sample can be obtained from the response of the ICP for an unknown sample. From the calibration curve, the gradient (m) and intercept (c) are used to calculate the concentration of the element. The quality of the calibration curve is determined by the regression (R2) value, which should be above 0.9990. A high R2 value means that the independent and dependent variables are directly proportional to each other with minimal error. The R2 value for WearCheck’s calibrations used is greater than 0.9999.

OUR PATH TO MASTERY OF SPECTROSCOPY

WearCheck’s elemental analysis began modestly with rotating filter spectroscopy (RFS). Back then, most laboratories used analytical ferrography to identify wear metals in lubricants, but it was slow, manual, and heavily dependent on the analyst’s expertise. By adopting RFS, WearCheck could deliver results much faster, run simultaneous multielement analysis, and work with very small sample volumes - giving us a clear competitive advantage.

As time and technology progressed, the Fast Oils Analyser ICP and the Accuris ICP were used. These computerised systems placed WearCheck at the forefront of oil analysis, as we were the only oil testing company in South Africa – and probably in the whole of Africa - to use advanced ICPs. They allowed for greater accuracy and sensitivity on all types of samples, with abilities to reach lower detection and quantification levels.

After the Accuris, the Varian ICPs were employed. These ICPs used automated dilutors to add the sample and dilute it before analysis. The automated dilutors unfortunately did not perform to our expectations for our high sample throughput, however the ICP still maintained WearCheck’s high standard of laboratory results.

In 2008, WearCheck moved over to the high-end models of ICP-OES Optima 7600 series - the latest technology in simultaneous multi-elemental analysis at the time, a technique which is still used today.

Through automated quality control, the instrument identified out-of-specification results, provided alerts, and halted analysis until the problems were rectified. It also used next-generation electronics with enhanced lifespan, performance, and improved signal-to-noise ratios and robustness, allowing WearCheck to analyse the most challenging lubricants with higher accuracy and precision, timeously. These ICPs demonstrate great potential for high throughput, while maintaining the high standard of accuracy and precision for our customers.

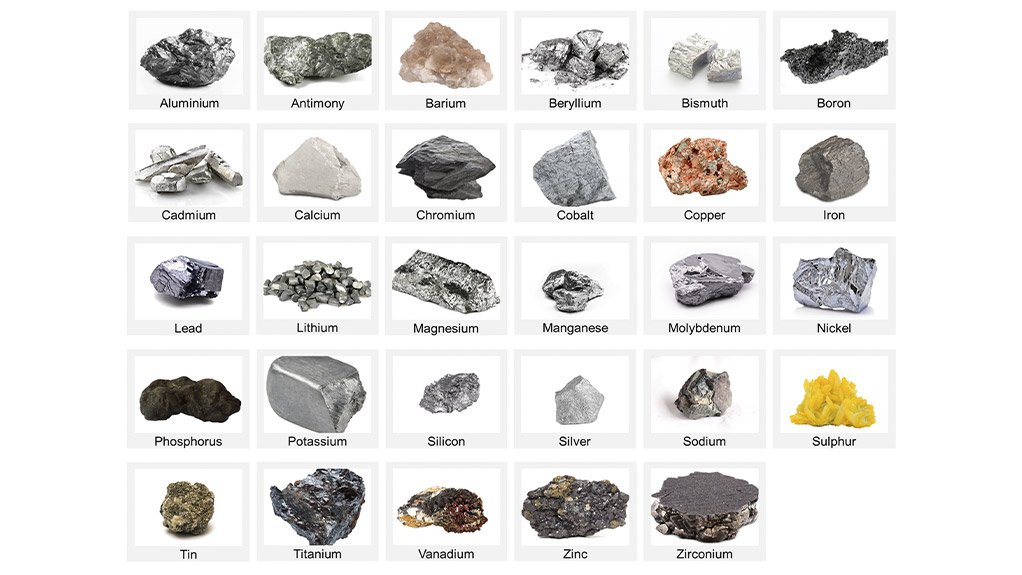

Today, WearCheck’s method is based on the industry standard ASTM D5185-184, and the ICPs are set up to process 120 samples per hour using an auto sampler. Each sample is read for 29 elements (Figure 7), eight times within a few milliseconds, before a final reading is taken. This allows for the proactive identification and correction of analytical challenges without affecting sample accuracy or reliability.

All our ICPs are calibrated daily, serviced annually, and biennially validated to ensure smooth operations all year around. The calibration process is a procedure used to tune the ICP to known elemental standards of known concentrations. These standards are based on certified reference materials (CRMs) containing a mixture of all possible elements that can be found in lubricants ranging from the additive packages to wear metals, including foreign contaminants. They are stable, homogenous oil samples that have been traceably certified for the element’s concentration, with its associated variations. To ensure that our calibrations are accurate, a range of quality-control standards is analysed. These are based on CRMs and real-world, certified quality-control samples. This ensures that the ICP is performing optimally for a wide variety of lubricants – from clean to degraded.

Although the Optimas are still used in some of WearCheck’s labs today, WearCheck is in the process of migrating to the latest model of ICPs in the industry. These new ICPs, armed with improved sensitivity, quick start-up and new advanced software models to reduce inter-elemental interferences, will ensure that our customers receive a consistent standard of reliable, accurate results.

The journey from initial to current techniques has been a rewarding experience for WearCheck, and is marked by growth, innovation, and continuous improvement. At WearCheck, our priority is not only to deliver fast, accurate results, but also to ensure that our clients fully understand and recognise the level of quality that supports them via our advanced instrumentation, methodology, processes and standards.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation