Pumps crucial to sugar processing – supplier

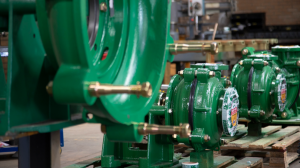

PUMPING INVESTMENT The investment in modern, efficient pump solutions can optimise sugar operations

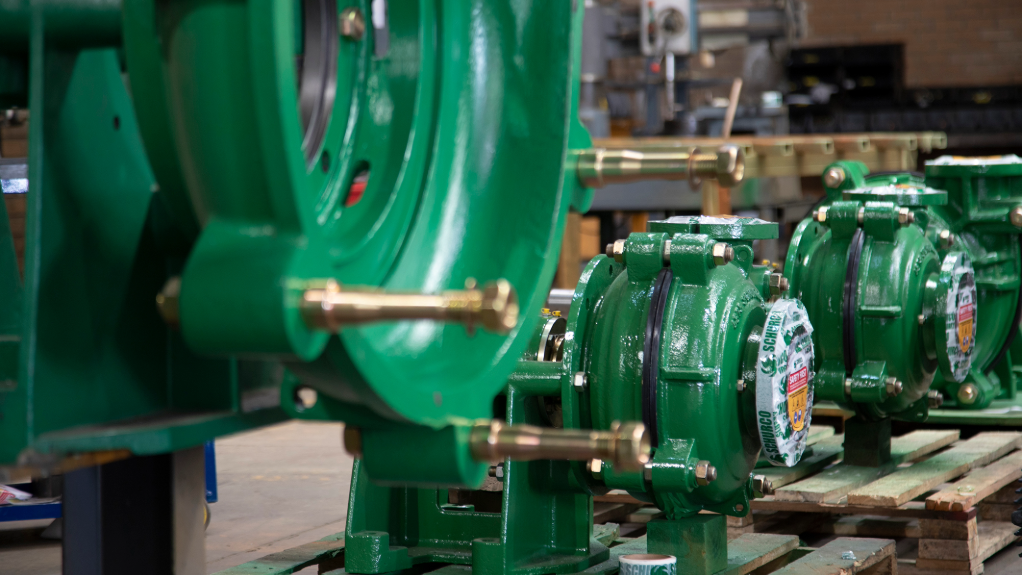

SHURCO SLURRY RANGE The range is designed for a variety of applications, extending from the milling phase through to centrifugation.

ONGOING R&D Ongoing R&D efforts are indicative of the industry-wide commitment to continuous improvement and innovation in pump technology

As the sugar industry continues to evolve in a rapidly changing market landscape, the investment in modern, efficient pump solutions and effective maintenance practices will remain vital, says pumps supplier Schurco Slurry process and technical specialist Donovan Higginson.

By doing so, sugar manufacturers can optimise their operations, reduce environmental impacts and maintain a competitive edge in the market, he explains.

This approach to managing and enhancing pumps technology underscores its role in the sugar industry, driving efficiencies, sustainability and innovation in an era of increasing environmental and economic challenges.

To that end, Higginson says the Schurco Slurry pump series is designed for a range of applications within sugar processing operations, extending from the milling phase through to centrifugation.

The versatility of these pumps is attributed to an extensive selection of material designs, pump and impeller configurations, and shaft sealing options. These pumps are also capable of processing the by-products of combustion, notably high concentrations of bottom and fly ash.

In addition, Schurco Slurry pumps are frequently used in flue-gas desulphurisation processes.

“Pumps are essential in the sugar refining process for the transportation of various liquids, including syrups and molasses, across different stages of refinement. The efficiency of these pumps is critical for the precise control of liquid movement, which is essential for maintaining optimal refining conditions and reducing product loss,” Higginson explains, noting that such efficiency plays a key role in cost management by minimising waste and maximising product yield.

He adds that the sugar production process generates a significant volume of wastewater, and that the use of advanced pump technology is crucial for effective wastewater management, and the facilitation of its movement to treatment facilities or disposal sites.

Efficient pumps systems are important for managing large volumes of wastewater, thereby minimising the environmental impact and the costs associated with wastewater treatment, which is especially pertinent when considering that the sugar industry is a significant producer of wastewater, Higginson highlights.

“Through regular maintenance and the correct selection of equipment, unexpected failures can be prevented, thus avoiding production disruptions and repair expenses. Schurco Slurry’s assistance in pump system design and total ownership cost management exemplifies the industry’s focus on maintaining continuous production and ensuring cost efficiency,” Higginson says.

Additionally, the malfunctioning of pumps can disrupt operations, leading to downtime and financial losses.

With Schurco’s comprehensive refurbishing programmes tailored for its own, and various other pumps, the company provides a swift and cost-effective solution to get operations back on track.

Schurco Slurry offers a service exchange programme for all its pumps and bearing assemblies to decrease downtime and related costs. User and artisan training is of prime importance to ensuring efficient pump operation, which is why Schurco Slurry offers a comprehensive training programme tailored to the customer’s requirements to aid in on site operations.

Innovation in pump solutions has also expanded the possibilities within the sugar industry, enabling the development of renewable-energy sources through the conversion of by-products such as molasses into ethanol or biofuels.

Moreover, these innovative solutions support the cogeneration of electricity using biomass or waste heat, enhancing operational sustainability and diversifying revenue streams.

This ability to optimise the transfer, mixing and treatment of by-products such as molasses or bagasse into value-added products also supports sustainability objectives by using all available resources.

Schurco Slurry’s ongoing research and development efforts are indicative of the industry-wide commitment to continuous improvement and innovation in pump technology, Higginson says.

He notes that, by addressing the evolving demands of the sugar industry and leveraging insights from related fields such as mining and chemical processing, Schurco Slurry is at the forefront of efforts to improve efficiency, reliability and availability in pump technology.

“The cross-pollination of ideas and technologies from various sectors has fostered a common ground for cost efficiency, demonstrating the interconnectedness of industries and the universal need for reliable, efficient pumps solutions,” Higginson says.

Schurco Slurry’s aim to enhance pump technology globally, to meet the demands across all industries it serves, highlights the importance of continuous research in increasing the efficiency of processes, he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation