Retrofits improve pump systems performance

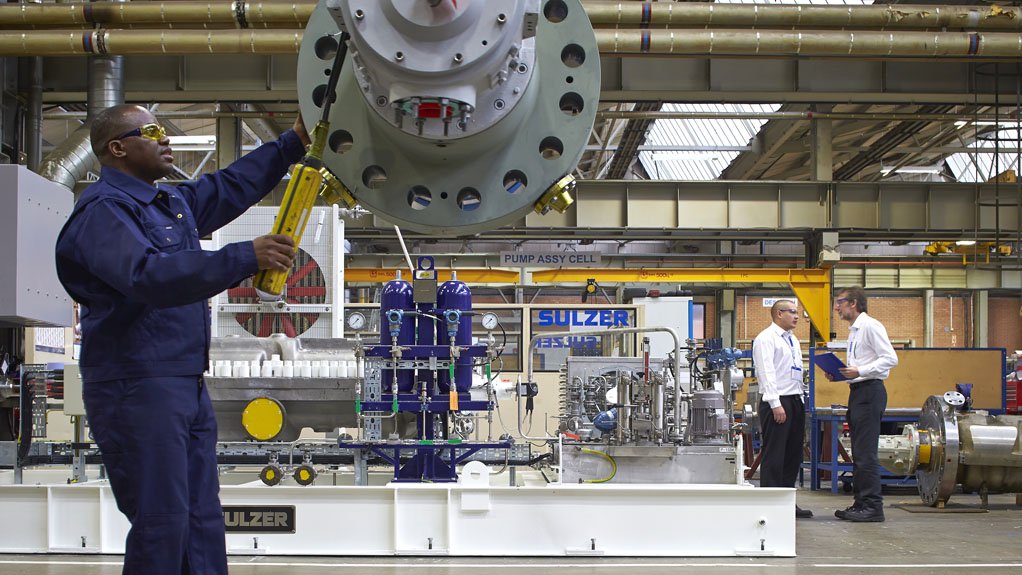

PUMPS MODERNISATION Sulzer's retrofits improves existing pumping equipment and systems

South Africa-based global pumps supplier Sulzer is considering innovative ways to assist its clients to save time, decrease costs and mitigate carbon emissions while complying with national environmental, health and safety regulations, says Sulzer retrofit segment manager Richard Morris.

“Over time, most industrial plant pumping systems change, which changes the pump duty requirements resulting in poor reliability and inefficient operation. “Together with this challenge, there have been changes to the regulatory health and safety requirements and standards; we see retrofitting existing equipment as the best solution to solve these challenges.”

He notes that Sulzer is currently working with customers in various industries, such as oil and gas, power, mining and bulk water transport, with the aim to transform ‘bad actors into star performers’, to improve reliability and increase mean time between repairs.

“We consider retrofits as an upgrade, or modernisation, of existing pumping equipment and systems. “This can be done through hydraulic re-rating, mechanical design updates, changing of materials of construction, addition of wear-resistant coatings, or upgrading of seals and seal systems to meet the latest standards required by the specific industry regulations.

Additional benefits to retrofitting existing pumping equipment include its cost effectiveness and shorter lead times, compared with purchasing new pumping equipment, with the added benefit of not disturbing the existing pump installation, and this makes it the perfect solution for our customers,” concludes Morris.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation