Save on compressed air with the Sandpiper EvolutionX and Versamatic Valor AODD pumps

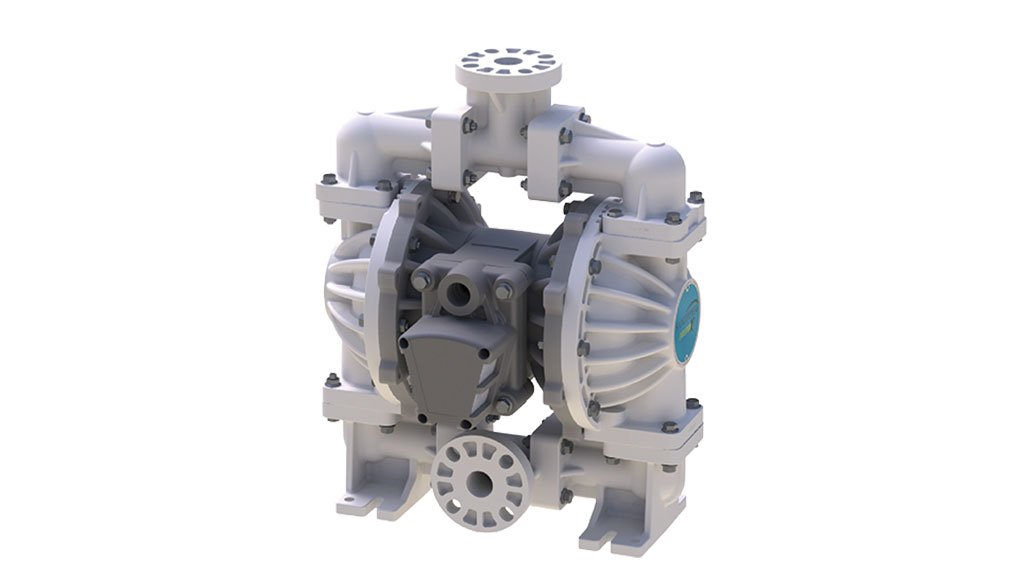

In the ever-changing realm of fluid handling, technological progress plays a vital role in improving efficiency and dependability. The forefront of these advancements is represented by the Sandpiper EvolutionX pump and the Versamatic Valor pump, both of which offer revolutionary technology and outstanding characteristics that cater to a wide range of industrial needs.

Performance

Relying on computational fluid dynamics software and rapid prototyping technologies during the design of the EvolutionX and Valor pumps has resulted in these pumps being the best performing 1-inch air-operated double-diaphragm (AODD) pumps on the market.

The EvolutionX and Valor pumps’ displacement of 0.83 litres per stroke is amongst the highest when compared to other 1-inch pumps, allowing these pumps to displace the same total capacity as the competition, but with fewer cycles. This will in turn increase the life span of the wear parts in the EvolutionX and Valor pumps as well as reduce the air consumed.

These increases in performance could speed up the processes in your plant, resulting in increases in overall output.

Efficiency

The EvolutionX and Valor also boasts best-in-class energy efficiency, using less air compared to other AODD pumps in its class.

This in turn reduces the wear on the com-pressor, resulting in a reduction in maintenance and down-time, and also increases the lifespan of the compressor.

A saving in air also equates directly to a saving in energy as less compressed air needs to be generated by the compressor. The reduction in energy used will also affect your carbon footprint and preserve the environment.

User-Friendly Maintenance

The maintenance of these pumps has been simplified and made hassle-free by incorporating multiple simple but thoughtful improvements to the design.

The air distribution side of the EvolutionX and Valor pumps have been redesigned to allow for the components that require the most maintenance in an AODD pump to all be contained in a simple-to-replace cartridge. Four bolts can be removed, giving access to the cartridge which can then be swapped out for a replacement cartridge, allowing the pump to be put back into operation as soon as possible. The removed cartridge can then be returned to the workshop where all the wear components can be replaced, and the cartridge can be ready to go back into another pump when needed. This design greatly reduces the time required to do repairs and thereby reduces down-time of the pump and plant, as well as freeing up the time that maintenance crews spend on pump repairs.

The main components of the pumps have been designed so that they are held together by a single universal size bolt, this allows these pumps to be disassembled to a great extent by only using a single size of spanner.

Stabiliser feet have also been added to the design of the centre-section of these pumps, preventing them from rolling back and forth when assembling the pump or doing maintenance on the air side of the pump.

These small improvements make these pumps a more pleasant and trouble-free experience to work with.

Connection Options

The EvolutionX and Valor pumps are available with different manifold configurations based on the pipework layout in your plant. Side-ported manifolds are available with adjustable feet to match the mounting bolt footprint of many of the competitors in the 1-inch AODD class. Alternatively, a three-piece manifold is available where the centre piece of the manifold can be rotated to face forwards, backwards, or to the top of the pump. The centre piece of the manifold could also be removed and the two elbows rotated. This configuration is ideal when the

pump is used in an application where it pumps two different substances simultaneously without the two substances coming into contact with each other. The paint industry has found much use for this configuration.

The Importance of OEM Parts

It is essential to use original equipment manu-facturer (OEM) parts to uphold the performance and durability of the Sandpiper EvolutionX and Versamatic Valor pumps. These OEM parts are manufactured and tested to meet the standards set out by the OEM, guaranteeing optimal performance and lifespan. The superior quality of OEM parts ensures reliability and longevity, minimising the risk of premature failures and prolonging the operational life-span of the pump. Additionally, OEM parts are engineered to seam-lessly integrate with the existing components of the pump. Further, the use of non-OEM parts will void any industrial certification that the pump may have, which could result in injury or death, as well as lawsuits due to pumps not conforming to set specifications.

The Sandpiper EvolutionX pump and Versamatic Valor pumps embody the latest advancements in fluid handling technology.

Their revolutionary design features and advantages deliver unparalleled efficiency, reliability and cost-effectiveness, making them ideal choices for a wide range of industrial applications. By investing in these innovative pumps, businesses can achieve increased productivity, reduced maintenance costs and a commit-ment to sustainability, ensuring a competitive edge in today’s demanding and dynamic industrial landscape.

Experience unparalleled efficiency and innovation with the Sandpiper EvolutionX and Versamatic Valor pumps, exclusively available through AxFlow AQS Liquid Transfer. As

the sole importer and distributor for these revolutionary AODD pumps in Africa, they are committed to providing you with the best in liquid transfer solutions. Do not miss out on this opportunity to elevate your operations—contact AxFlow AQS Liquid Transfer today and transform your productivity.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation