SEW-EURODRIVE’s global sustainability strategy in Africa

SEW-EURODRIVE’s products allow for reduced raw material consumption, increased stock-keeping and enhanced application flexibility and efficiency

Power transmission solutions and drive technology manufacturer SEW-EURODRIVE aims to align its global sustainability strategy with the unique needs of African industries.

“SEW-EURODRIVE’s global strategy, which focuses on sustainability and responsible sourcing, is easily adaptable to local African contexts,” says SEW-EURODRIVE business development electronics manager Willem Strydom.

He identified two crucial trends in the drive technology market as an example: efficiency and digitalisation.

“SEW-EURODRIVE’s MOVI C product portfolio is at the forefront of these trends, offering enhanced efficiency and enabling businesses to modernise their operations through advanced automation solutions,” he elaborates.

SEW-EURODRIVE national sales and marketing manager Jonathan McKey agrees, mentioning the implementation of a sustainability report outlining SEW-EURODRIVE’s policies on resource use, procurement and human development, stressing the importance of job creation and skills development as key priorities for Africa.

A further significant part of SEW-EURODRIVE’s approach to sustainability in Africa revolves around energy efficiency and renewable power, he explains.

“About 60% of SEW-EURODRIVE’s current operations are powered by solar energy, greatly reducing demand on the local grid. This shift towards renewable energy, coupled with digi- talisation efforts like paperless workflows, globalised assembly processes, and state-of-the-art equipment, ensures minimal waste and enhances efficiency,” he says.

McKey also emphasises the balance between ethics and business sense in SEW-EURODRIVE’s sustainability goals, explaining that both motives are deeply interwoven.

Key Trends

SEW-EURODRIVE’s diversification from purely mechanical systems to a combination of motor and variable speed drive technologies has enabled its customers to optimise their operations. Strydom highlights the importance of preventative maintenance over reactive approaches, pointing to SEW-EURODRIVE’s offerings such as energy assessments and customised solutions that can deliver up to 40% power savings.

“SEW-EURODRIVE is actively implementing sustainability projects across various industries, from sectors such as macadamia farming to food and beverage, and automotive industries, where SEW-EURODRIVE conducted energy assessments and proposed more efficient solutions,” notes Strydom.

The company’s emphasis on tailored solutions over “one-size-fits-all” products is also a point of focus, with McKey noting the significance of offering specialised products that address specific customer needs without unnecessary overdesign. He further emphasises that SEW-EURODRIVE provides add-on services such as consultations with engineers at no additional cost to the customer, enhancing the overall value of their solutions.

SEW-EURODRIVE’s product development is a continuous process, and constant analysis and refinement of its portfolio demonstrates its drive to futureproof its products.

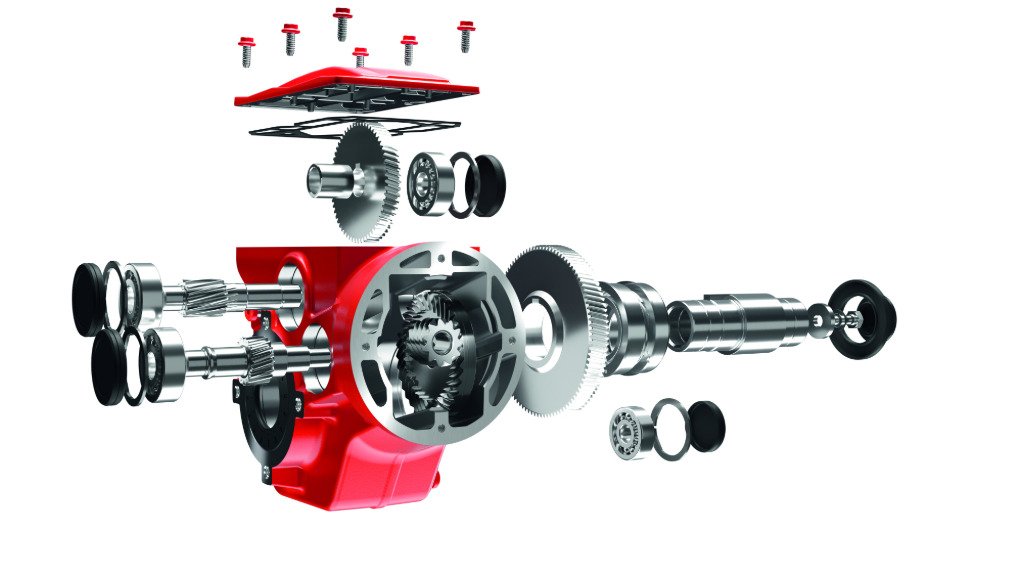

“The modular design philosophy behind SEW-EURODRIVE’s products not only reduces raw material consumption but also increases flexibility and efficiency. By minimising product variations, SEW-EURODRIVE ensures that it can maintain sufficient stock levels for clients, ultimately improving customer satisfaction and operational efficiency,” adds Strydom.

He points out that SEW-EURODRIVE’s technologies are having a transformative impact on global markets and African industries alike, where immediate results in energy savings and improved operational efficiencies are already apparent.

McKey highlights SEW-EURODRIVE’s role as a leader in automation, with its technologies setting new trends based on customer feedback. “A steering committee meets regularly to discuss product enhancements, ensuring that SEW-EURODRIVE remains ahead of the curve by continually refining its offerings. This customer-centric approach aligns with SEW-EURODRIVE’s overarching philosophy of providing reliable solutions, not just products,” he elaborates.

Differing Needs Across Continents

On the question of whether African customers have different needs compared to other continents, McKey notes that, while there are many similarities, Africa presents unique opportunities, particularly in its willingness to embrace modernisation and innovation.

Strydom echoes this viewpoint, explaining that Africa’s dynamic geography and diverse climates often necessitate a more adaptable and responsive approach to technology and solutions.

“SEW-EURODRIVE’s ability to cater to a variety of customer needs, both across Africa and globally, is a key differentiator,” says Strydom.

Looking to the future, SEW-EURODRIVE is investing heavily in Africa, with McKey pointing out the company’s plans to expand its presence with new production, assembly and repair facilities.

“This expansion is driven by the growing demand for premium original-equipment manufacturer capabilities and after-sales services on the continent,” he says.

SEW is committed to adding value to Africa’s industrial landscape by becoming more self-sustaining and resilient, he adds.

SEW-EURODRIVE’s decentralised manufacturing principles have been crucial in maintaining operational resilience during periods of global disruption, such as the Covid-19 pandemic. McKey highlights that this approach ensures consistent quality across all SEW-EURODRIVE manufacturing sites worldwide, allowing the company to tap into various countries and regions during supply chain bottlenecks.

“With robust stockholdings and the ability to replenish supplies as needed, SEW-EURODRIVE has maintained quality and efficiency, no matter the external challenges. The company is optimistic about the future and confident in its ability to adapt and thrive,” McKey concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation