Tough seal ensures longevity of tapered roller bearing

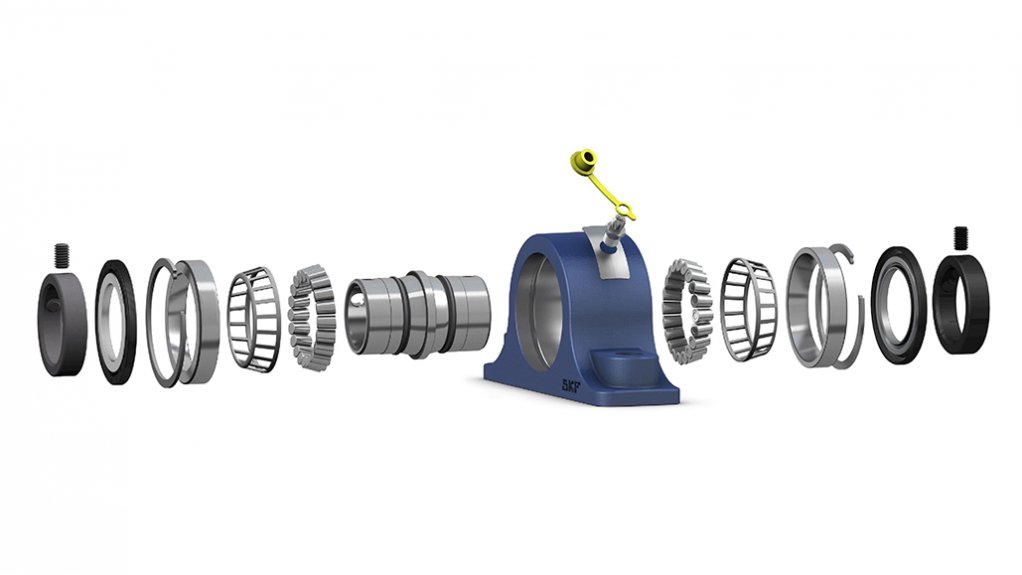

The performance and product life of a new mounted tapered roller bearing has been extended by pairing it with a superior seal.

SKF explains that adding the robust seal has created a new product that has proven to survive in contaminated environments for more than 600 hours – 10 times longer than any competitor product.

The mounted tapered roller bearing, known as a Type E bearing, incorporates SKF’s CR Seal and has helped to extend service life by almost eliminating ingress of contamination, even under harsh conditions.

“In mud-slurry tests, our seal withstood more than 600 hours with zero contamination ingress,” says SKF director of product management North America Eric Brubaker. “Rival products saw ingress at 50 hours or earlier.”

The mounted tapered roller bearing is used when an increased thrust load is needed with limited axial movement, making it particularly suited for demanding industries such as mining, aggregates and cement. Potential applications include materials handling equipment, such as belt feeders and screw conveyors, and process machinery including grinders, shredders and mixers. By improving seal performance, the units’ reliability and uptime can be increased.

CR Seals offers several features that help prevent contamination. The use of hydrogenated nitrile rubber resists both wear and high temperatures, while a full rubber outside diameter improves static sealing within the housing. Multiple sealing lips exclude contamination such as dirt, mud, water, sand and powder. The seal also allows the bearing to be relubricated without risking damage to the sealing lips.

The Type E bearing can also be used in conveyors and process equipment in lumberyards, pulp and paper, metals and food processing.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation