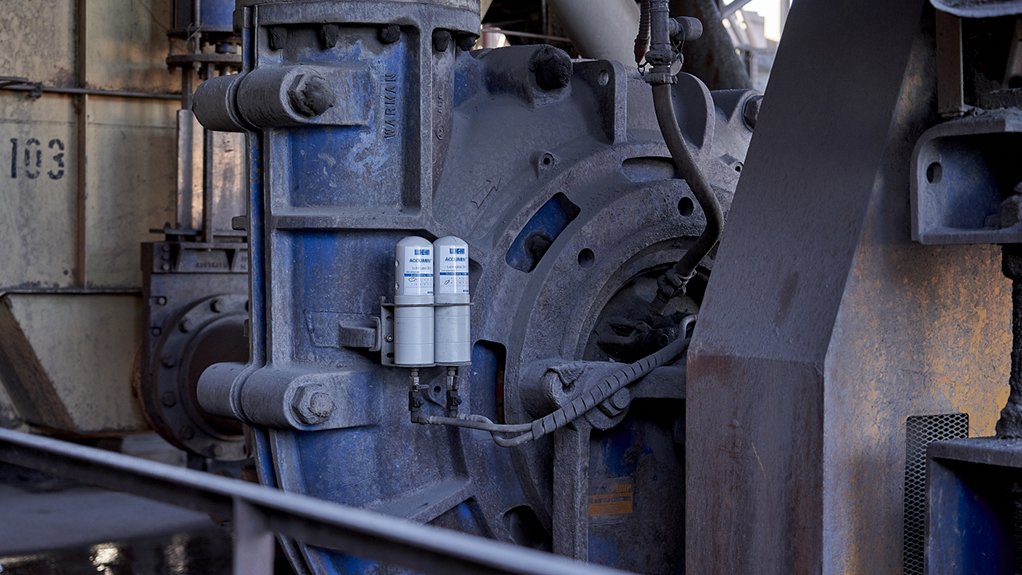

Weir Minerals launches Accumin™ lubricators worldwide to optimise Warman® pump performance

The Accumin™ automatic lubrication system helps customers get the most out of their critical assets by preventing bearing failures and reducing Total Ownership Costs.

Weir Minerals is proud to announce the global launch of its Accumin™ lubricators, following international demand for the superior-quality grease lubrication which has been ensuring optimal performance for equipment such as Warman® slurry pumps in APAC since 2014.

Across more than 100 sites, the Accumin™ lubrication system has proven itself an efficient way of preventing expensive bearing assembly failures, reducing maintenance downtime and promoting safety by decreasing the amount of manual interface to keep equipment performing.

“At Weir Minerals, we make the market leading slurry pump for mining applications, but we can’t always control what happens when it gets to site. Between dust, overflow and gland seal leaks, lubrication is a vital tool in the constant battle to keep machinery going. Having an Accumin™ lubrication system fitted prevents over and under greasing, protects equipment from bearing failures and frees up man hours for more critical tasks,” says Michael Roinich, Accumin™ Specialist, Weir Minerals.

“When we offer Weir Minerals equipment with an Accumin™ lubrication system installed, what we’re really doing is giving that equipment its best shot at a long and productive working life.”

Made in Germany, Accumin™ canisters are produced in 125cm3 gas driven, 120cm3, 250cm3 and 500cm3 electro-mechanically driven configurations and can be deployed up to five metres away from the lubrication point, allowing easy and efficient access to the mount. The electro-mechanical driven lubricator dispenses a consistent dosage of lubricant, regardless of ambient temperature. The system delivers 6 bar of operating pressure and can be easily monitored via an LCD display, flashing LED alert system and a transparent grease cartridge.

“Designed to meet the arduous demands of the mining industry, Accumin™ single-point lubricators set the global standard for lubricating Warman® pumps and other grease-lubricated, mission-critical mining equipment supplied by Weir Minerals. We’re excited to share our market-leading, best-practice system with mines around the world who are embracing new technologies to simplify their operations,” says Mr Roinich.

Making the move to Accumin™ lubricators helped an Australian iron ore mine to save almost AU$120,000 each year in downtime reduction, pump rebuilds and bearing assembly replacements.

Accumin™ lubricators are now available worldwide on new pumps, through Weir Minerals’ aftermarket spare parts supply channels and via our unrivalled service centre network.

Weir Minerals Africa

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation