Why partnering with Delba Electrical is a smart choice

In the fast-paced world of industrial operations, the reliability and efficiency of equipment are paramount. For companies reliant on electrical rotating machines to power their operations, ensuring these machines run smoothly and efficiently is critical to maintaining productivity and reducing downtime. This is where the leader in electrical rotating machine repair and maintenance, Delba Electrical, becomes an invaluable partner. Here’s why partnering with Delba Electrical is a smart choice for industrial companies.

Unmatched Expertise and Experience

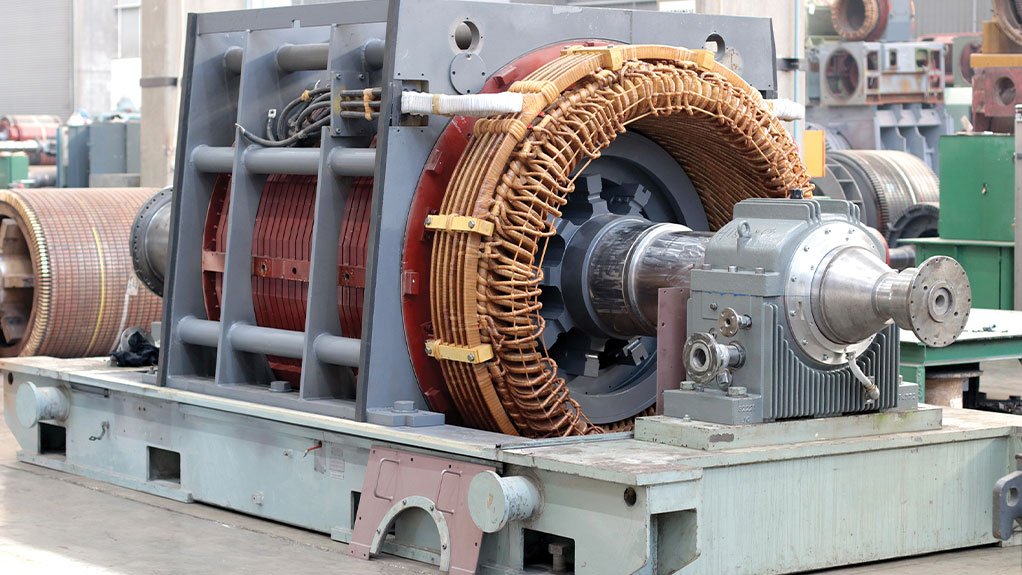

Delba Electrical has been at the forefront of the electrical rotating machine repair industry for decades, accumulating a wealth of knowledge and experience. Our team of highly-skilled artisans have encountered and successfully addressed a wide range of challenges across different industries. This expertise allows us to handle everything from routine maintenance to complex repairs of large, high-powered machines. When you partner with Delba Electrical, you are tapping into this vast reservoir of experience, ensuring that your machines are in the hands of trained professionals who understand the intricacies of every type of machine.

Comprehensive Service Offering

At Delba Electrical, we offer a full spectrum of services designed to meet all your machine repair and maintenance needs. Whether it is routine inspections, preventative maintenance, emergency repairs, or complete rewinding of rotating machines, we have got you covered. Our comprehensive approach means that you do not have to juggle multiple service providers for different aspects of machine care. This not only simplifies the process for you but also ensures consistency in the quality of service delivered.

State-of-the-Art Facilities and Technology

Delba Electrical prides itself on using the latest technology and state-of-the-art facilities to deliver top-notch services. Our vacuum impregnation facility, for instance, is the largest and most modern in Africa, allowing us to provide superior insulation services that significantly enhance the durability and performance of your rotating machines. We continually invest in advanced diagnostic and repair tools to ensure that our services are not only effective but also efficient. This commitment to technological advancement translates into faster turnaround times and more reliable repairs for our customers.

Commitment to Quality

Quality is at the core of everything we do at Delba Electrical. We understand that inferior repairs can lead to costly breakdowns and extended downtime, which is why we adhere to the highest standards of quality in every project we undertake. From the moment a machine enters our facility, it undergoes rigorous testing and inspection processes to identify any underlying issues. Our quality control team ensures that every repair meets or exceeds original equipment manufacturer standards before the machine is returned to the client. This unwavering commitment to quality has earned us a reputation as a trusted partner in the industry.

Energy Efficiency and Sustainability

In today’s industrial landscape, energy efficiency is not just a buzzword; it is a necessity. Machines that operate efficiently consume less energy, leading to significant cost savings and a reduced environmental footprint. Delba Electrical is committed to helping our clients achieve greater energy efficiency through our repair and maintenance services. We conduct thorough assessments of your machines to identify areas where efficiency can be improved, and we implement solutions that not only extend the life of your machines but also reduce their energy consumption. Partnering with Delba Electrical means you are not just getting your machines repaired; you are making a positive impact on your bottom line and the environment.

24/7 Support and Quick Turnaround

We understand that electrical rotating machine failures do not always happen during regular business hours. That is why Delba Electrical offers 24/7 support to our clients. Our Field Services team is always on standby to respond to emergencies, ensuring that you experience minimal downtime and can get back to full operational capacity as quickly as possible. Additionally, our efficient processes and well-equipped facilities allow us to provide quick turnaround times without compromising on quality, helping you keep your operations running smoothly.

Proven Track Record

Delba Electrical’s long history of successful projects speaks for itself. We have partnered with numerous industrial companies across various sectors, consistently delivering results that exceed expectations. Whether it is rewinding one of the largest 19.7 MW squirrel cage motors or providing routine maintenance for smaller electrical rotating machines, our track record of excellence is a testament to our reliability and expertise.

Choosing Delba Electrical as your electrical rotating machine repair and maintenance partner is a smart decision for any industrial company. Our unmatched expertise, comprehensive services, state-of-the-art facilities and unwavering commitment to quality make us the go-to partner for ensuring the longevity and efficiency of your machines. By partnering with us, you gain a trusted ally dedicated to keeping your operations running smoothly, efficiently and sustainably.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation