Anglo’s fuel-cell truck operating ‘akin to its diesel counterpart’

Anglo American’s big nuGen hydrogen-powered truck is currently functioning “akin in operation and cost to its diesel counterpart”, says Anglo American market development principal Fahmida Smith.

The global mining company in May unveiled its nuGen truck, with a 2 MW hybrid battery/hydrogen fuel-cell powerplant replacing the diesel engine.

The truck, a prototype of what is the world's largest hydrogen-powered mine-haul truck, was designed by Anglo American and US company First Mode.

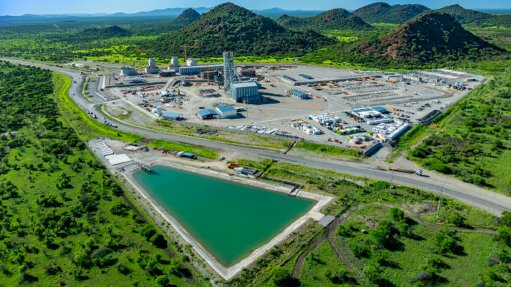

The vehicle, which is being tested at the Mogalakwena platinum mine, in Limpopo, weighs 220 t, with a load capacity of 290 t, giving it a total weight of 510 t.

Smith says roughly 80% of Anglo American’s carbon dioxide emissions come from diesel use, with mining haul trucks, in turn, responsible for most of these emissions.

“One of these trucks use 900 000 l of diesel a year. That presented a key opportunity for us to decarbonise.”

Smith says global truck manufacturers told the mining group that there “was no way” it was possible to decarbonise a truck of that size.

This prompted Anglo American to tackle the development in-house.

Smith says the group is continuing the monitor and test the vehicle’s performance.

The fuel-cell truck is, however, only one of four hydrogen projects the company is pursuing.

Anglo American is also working with a number of partners, such as Bambili Energy, Sasol and TotalEnergies, to create the country’s first hydrogen corridor, with a focus on logistics – trucks and buses that use hydrogen.

“That is then three projects. A fourth one is to develop, with Bambili, fuel cells for stationary applications – in particular, buildings and offices.”

Bambili Energy CEO Zanele Mbatha says she believes South Africa will have fuel-cell trucks on the road “by 2024, 2025”.

From Grey to Green

Sasol is currently one of the largest producers of grey hydrogen in the world, says

Sasol hydrogen programme management head Rilet Davison.

“We’ve got that experience. We know how to handle the product. We know how to produce the product and how to convert the product.”

Davison says this gives Sasol a strategic advantage in that it can use its existing assets in Secunda and Sasolburg to produce sustainable products such as green hydrogen.

Green hydrogen is generated by renewable energy, or from low-carbon power. Green hydrogen has significantly lower carbon emissions than grey hydrogen, which is produced by steam reforming of natural gas, which currently makes up the bulk of the hydrogen market.

Green hydrogen is, however, still much more expensive to produce than grey hydrogen.

One of the projects Sasol is targeting is to convert its Sasolburg operation to green hydrogen in a number of ways.

“We recently announced our collaboration with ArcelorMittal South Africa from a [green] steel manufacturing and application point of view,” says Davison.

“A key demonstration we want to do for Sasolburg and the Vaal Triangle is to look at three different things. We already have an electrolyser – we are in the process of completing that, with the first production scheduled towards the end of 2023.

“Now the output of that electrolyser will be used in demonstration projects to incubate local demand and supply, and to supply the green hydrogen to offtakers.”

“For Secunda, where we currently produce synthetic aviation fuels, we have the opportunity to convert from grey to green hydrogen,” notes Davison.

“We have the synthetic fuels, but, in future, we’ll have sustainable aviation fuels.”

Davison says Sasol already has a demonstration project, through a consortium, working towards production of 50 000 t/y.

“If we can ramp that up in the future, OR Tambo [International Airport] can become a sustainable aviation hub.”

* Smith, Mbatha and Davison spoke at the Science Diplomacy for Economic Development (Hydrogen Economy) workshop in Cape Town.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation