Better hydro efficiency through pump, turbine tech

LANTERN RINGS The introduction of Vesconite Hilube’s lantern ring applications prolonged lifespan and reduced maintenance efforts

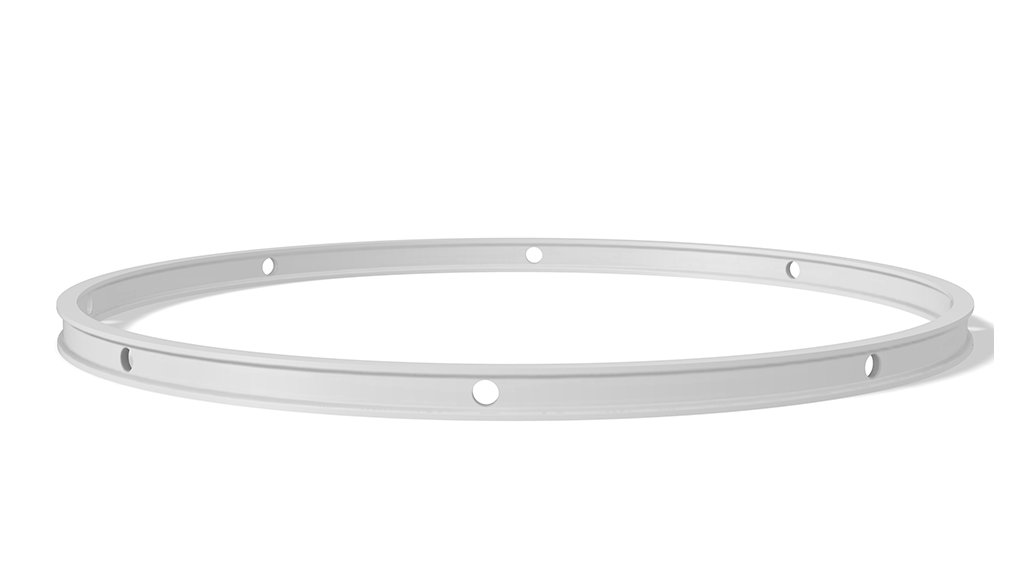

MONIQUE POTGIETER These seemingly minor components play a vital role in pumps and hydro turbines, ensuring the proper influx of cooling water to the packing

Early attempts to replace conventional metallic-type lantern rings with polymers, such as nylon, yielded discouraging results compared to metallic lantern rings in the water engineering industry, deterring the industry from exploring alternative solutions.

However, a recent installation of Vesconite Hilube lantern rings at the iconic Hoover Dam hydropower plant in the US could mark a pivotal moment in the industry regarding the use of advanced polymers in water engineering equipment, the company says.

“The adoption of [polymer supplier] Vesconite Bearings’ Vesconite Hilube in place of traditional metallic lantern rings represents a gradual yet definite embrace of alternative materials and cutting-edge technology within the water engineering sector,” sales engineer Monique Potgieter notes.

She explains that, initially, turbines were equipped with cast iron wear rings, the primary choice for many years despite evident limitations.

One of the primary challenges faced by the engineers at Hoover Dam was corrosion, a prevalent issue in arid regions such as the dam’s location between Nevada and Arizona. Hard water, laden with high mineral content, caused damage to traditional lantern ring materials, leading to the formation of rust particles in the area surrounding the lantern rings.

Vesconite Hilube, however, is impervious to the corrosive effects of hard water, and its introduction into lantern ring applications prolonged their lifespan and reduced maintenance efforts required.

“These seemingly minor components play a vital role in pumps and hydro turbines, ensuring the proper influx of cooling water to the packing,” Potgieter explains.

The packing, or stuffing box, seals off the pumped medium or, in the case of hydro turbines, the water that drives the turbine’s rotation.

Proper maintenance of these components enhances sealing effectiveness and prolongs the stuffing box’s lifespan, thereby minimising water wastage and increasing the efficiency of pumps and turbines.

“Introducing Vesconite Hilube in lantern ring applications instils confidence in users that this material doesn’t suffer from water swell issues seen in some other polymers, and encourages them to use Vesconite Hilube in primary applications in pumps and hydro turbines, aligning with the material’s intended purpose,” notes Potgieter.

She explains that in vertical pumps, it is used in line shaft bearings and casing wear rings. In hydro turbines, Vesconite Hilube is frequently employed in water lubricated main shaft bearings and grease-free wicket gate bearings, link arm bushings, change ring wear pads and vertical wear guides.

In South Africa, where the need for reliable renewable-energy sources is paramount, Vesconite Hilube can contribute to continuous operation with minimal breakdowns and maintenance outages in hydroelectric plants.

“We are running ongoing projects to quantify the efficiency increase in pumps when Vesconite Hilube bushings and wear rings are used,” says Potgieter, who adds that this “reaffirms its positive impact on global energy consumption”.

“In the hydro sector, Vesconite Bearings is closely monitoring installations of our greaseless and water lubricated bushings in hydro turbines to monitor their performance and affirm the suitability of internally lubricated materials to replace traditional greased bearings without compromising performance or wear life.

“This innovative approach holds the promise of further optimising hydropower systems, making them more sustainable and efficient,” she comments.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation