Bevcan’s Springs plant converts cans from steel to aluminium

From Creamer Media in Johannesburg, this is the Real Economy Report.

South Africa’s sole beverage can manufacturer Nampak Bevcan has converted its manufactured cans from tin-plated steel cans to aluminium cans as part of its commitment customer satisfaction. Sashnee Moodley has the story.

Sashnee Moodley:

Bevcan’s Springs plant’s first manufacturing line was converted to aluminium in June and has the capacity to manufacture 3 000 cans a minute. Bevcan GM Corrie Botha gives an overview of the manufacturing line conversion at the plant.

Bevcan GM Corrie Botha:

The Springs plant was the first plant to be converted to aluminium. We started our first line up at the end of May, basically June this year. We finalised the commissioning phase and we are in the optimisation phase of line one. We will have the second line converted to aluminium by November this year and then the third line at Springs will be converted to aluminium by next year May or June. The intention is to have the entire Springs plant only supplying aluminium cans. The business does have plans to convert some of its other plants in Cape Town, Rosslyn and hopefully Angola as well to aluminium. It will depend on the market and what the market requirement is.

The cans in the international market are mostly made from aluminium and the customer also required us to move over to aluminium can-making and, therefore, our whole move is really customer driven. The advantages: of course we can serve the customer better because that’s what he wants and then of course there are some secondary advantages from a looks point of view. Recycling and the obvious advantages form a branding point of view but the big thing is that we serve the customer, that’s why we went for aluminium.

We are currently running the aluminium can line at 2 500 cans per minute but the line has the capacity to run at 3 000 cans a minute.

Shannon de Ryhove:

Other news making headlines this week: South Africa’s labour market is still ‘inherently unstable’ after the auto strike ends, says BMW; and, BMG expands its offering as it enters a new partnership.

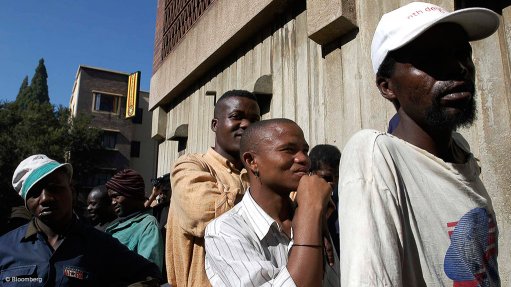

BMW says the labour situation in South Africa remains "inherently unstable" and it has no plans to reverse a freeze on expansion, even after car parts makers ended a four-week strike. Car-makers told Reuters they were hoping to return to full production, after parts manufacturers agreed to a three-year wage deal with the National Union of Metalworkers of South Africa.

Video courtesy Reuters

Engineering solutions provider Bearing Man Group has announced the expansion of its range of pneumatic and hydraulic filtration products and systems to include technologies from global motion and control specialist Parker Hannifin Corporation.

BMG sales director Ian King

That’s Creamer Media’s Real Economy Report. Join us again next week for more news and insight into South Africa’s real economy.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation