BMW, Mini to launch 100% vegan interiors in 2023

The BMW Group plans to launch its first vehicles featuring completely vegan interiors next year. It will be available in both BMW and Mini models.

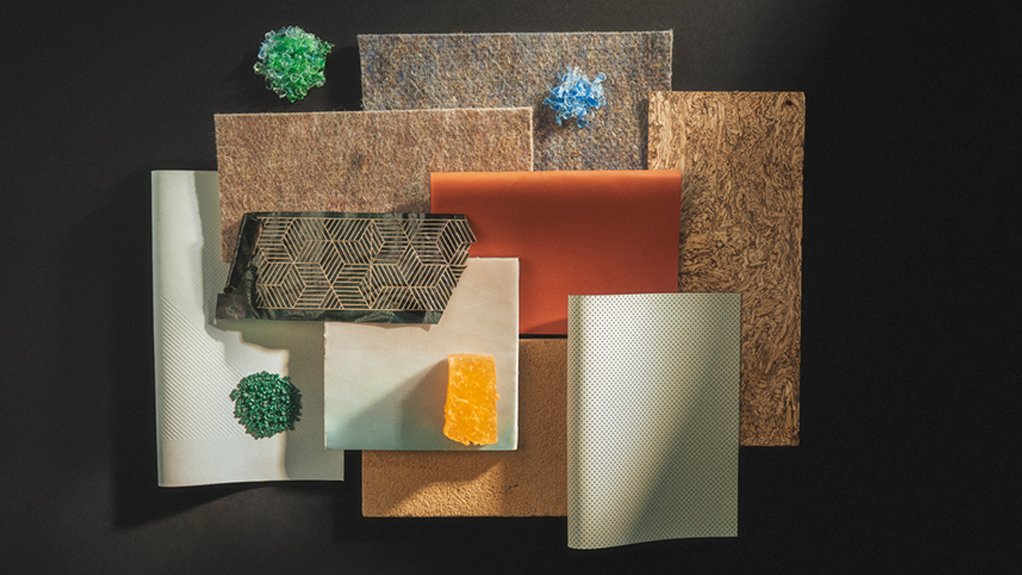

The German manufacturer says this advance is made possible primarily through the development of materials with leather-like properties.

“It will be possible to also use these materials for steering wheel surfaces, which must fulfil demanding criteria when it comes to feel, premium appearance and wear resistance,” notes the group.

BMW believes the demand for vegan and leather-free interiors is set to increase further in the near future, especially in the US, China and Europe.

The launch of such interiors will also aid the manufacturer in its ambition to reduce carbon dioxide (CO2) emissions over the lifecycle of a vehicle as it move towards climate neutrality, which is to be achieved by 2050 at the latest.

“Replacing raw materials of animal origin makes a significant contribution to increasing sustainability in vehicle production,” notes BMW.

“The introduction of a new surface material for steering wheels will see the proportion of vehicle components that contain traces of raw materials of animal origin fall to less than 1% in the respective BMW and Mini vehicles.

“As a result, these materials will now only be found in areas that are not visible to the customer, for example in various waxy substances such as gelatine used in protective coatings, lanolin in paints, tallow as an additive in elastomers and beeswax as a flux for paints.”

The new steering wheel surface material reduces carbon dioxide equivalent emissions along the value chain by about 85% compared with leather, says the company.

Up to now, most of the emissions linked to leather – about 80% – were in the form of methane gas from cattle rearing.

The remaining 20% was accounted for by processing of the cowhide, which is highly energy- and water-intensive.

Climate Neutrality

To achieve the group’s goal of climate neutrality, BMW says it is relying on the use of green electricity in production and in the supply chain, a consistently increased proportion of secondary materials and natural raw materials, efficient electric motors and combustion engines and a high recycling rate.

For example, the floor mats for various models are made from mono-material, thus avoiding material mixes that are difficult to recycle.

As a result, BMW saves around 23 000 t of CO2 and an additional 1 600 t of waste a year, since the recycled floor mats and waste material are also reused within the production process.

Research and development in the field of secondary raw materials and sustainable materials are also a priority.

BMW says it is working with start-up companies to develop bio-based materials.

Compared with the synthetic leathers previously used, these result in about 45% lower CO2 emissions.

Mirum, which is 100% bio-based and petroleum-free, has the potential to mimic all the properties of traditional leather.

Another new material, Deserttex, is made from pulverised cactus fibres with a bio-based polyurethane matrix.

“With these materials, replacing raw materials of animal origin can be combined with a significant reduction in CO2,” says BMW.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation