Brasco Industrial Filtration

This article has been supplied.

Dust control solutions leader Brasco Industrial Filtration recently reinforced its reputation for excellence with the design, manufacture and installation of a state-of-the-art reverse pulse cartridge filter system at a prestigious cement factory in the East Rand, Gauteng. This project is a shining example of Brasco's unmatched expertise and ability to deliver sophisticated, tailored filtration solutions that meet the rigorous demands of heavy industrial environments.

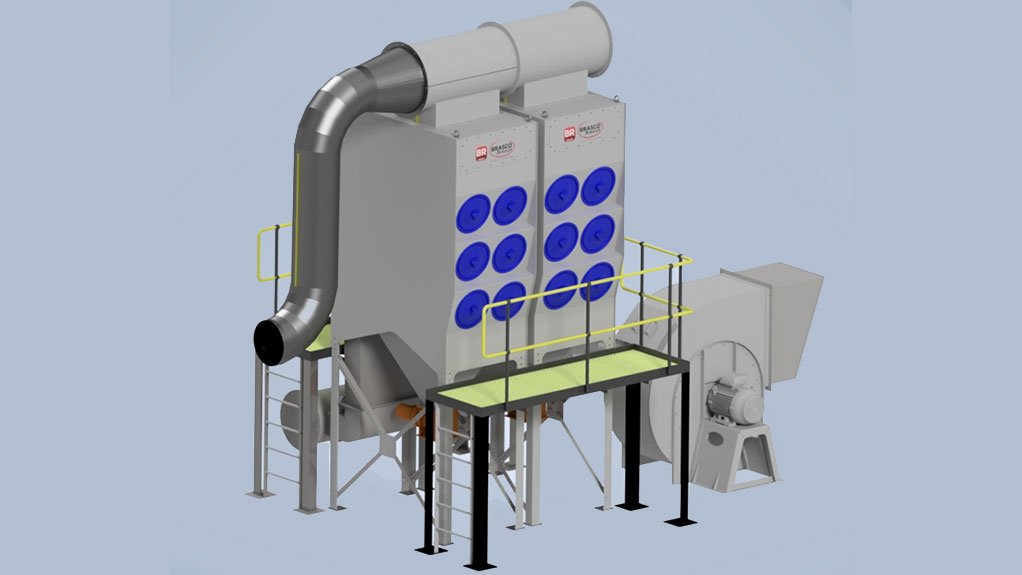

The meticulously crafted system was engineered to serve a comprehensive sample preparation laboratory, equipped with jaw crushers, rotary splitters, pulverisers and ring mills. In such a dust-intensive setting, Brasco designed a robust twenty-four-cartridge reverse pulse filter unit, paired with a powerful direct-driven 15 kW fan set. This powerful combination ensures that dust is efficiently captured and clean air is consistently released, maintaining a safe and compliant working environment.

In keeping with Brasco's attention to detail, the system includes dual rotary valve discharge points and an extensive network of interconnecting galvanized ducting and hoods, strategically positioned to capture dust at its various generation points. The design also features a rectangular duct with a 45°cutback cowl and vermin screen at the fan discharge, effectively expelling purified air into the atmosphere, underscoring Brasco’s commitment to environmental stewardship.

To enhance the system's usability and maintenance, Brasco provided a custom access platform equipped with a cat ladder, allowing easy access to the front of the filter unit for seamless removal and replacement of filter cartridges. At the client’s request, an additional access platform and cat ladder were installed at the rear, ensuring unobstructed access to the pulsing valves and pulse controller, further demonstrating Brasco’s dedication to client satisfaction.

This project was executed flawlessly, within budget and on schedule, exemplifying the seamless collaboration between Brasco’s in-house design team, drawing office, and project office. The successful commissioning and handover of this sophisticated system is a testament to Brasco Industrial Filtration’s leadership in delivering high-performance, tailor-made dust control solutions that set the standard in the industry.

Moreover, this project is one of over 200 filtration systems that Brasco Filtration has successfully designed, manufactured and installed to date. Each installation further solidifies Brasco's position as a trusted industry leader, known for its unwavering commitment to innovation, quality and customer satisfaction. This impressive track record highlights Brasco’s unparalleled expertise and its role as a key player in advancing the field of industrial filtration.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation