Broad view of water treatment options advised by consulting firm

WETLANDS A key responsibility of public sector water regulators is the maintenance of water resource quality in rivers, streams and other natural water bodies

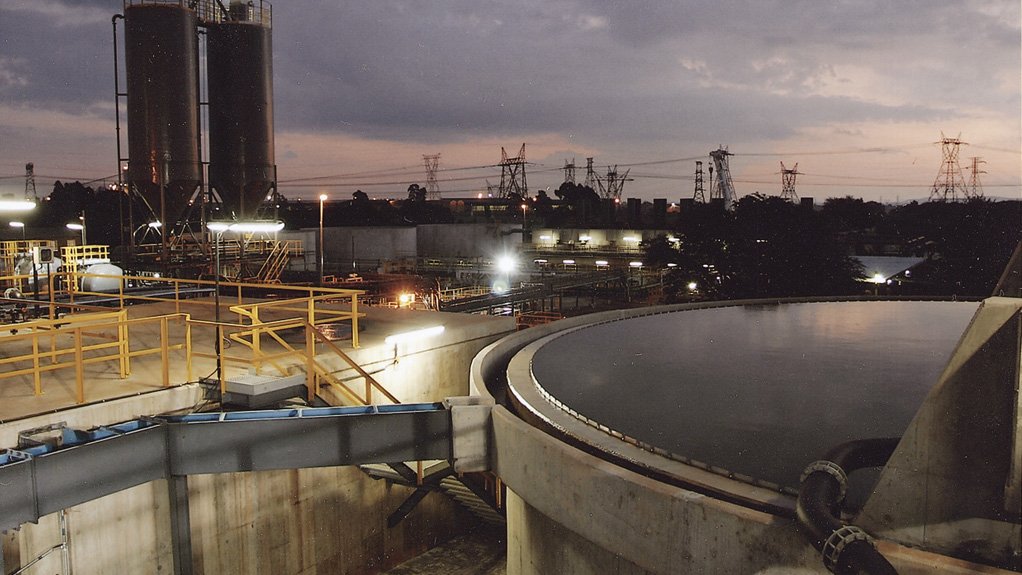

INDUSTRIAL WATER TREATMENT Given the downsides of many water treatment options, companies should make sure that all other less problematic solutions are in place before turning to treatment

A broad view should be taken when considering the options for treating water, says consulting engineering firm SRK Consulting principal engineer Xanthe Adams.

Complying with water quality limits set out in water use licences is imperative for mines, industrial organisations and other authorised South African water users, she says.

With increasingly stringent quality requirements and more enforcement, treating discharge water to achieve specified limits is being discussed more frequently.

“Improved water stewardship is a growing theme in business sustainability as South African companies increasingly recognise water risks and learn to manage them. The country’s semi-arid status has long been understood but its implications are now being more keenly felt – especially considering factors such as urban migration, economic growth and climate change,” she says.

Adams highlights that a key responsibility of public sector water regulators is the maintenance of water resource quality in rivers, streams and other natural water bodies. Water use licence holders must generally comply with specified quality limits set for water discharged into natural water courses.

Many users, both mining and industrial, may now be faced with having to meet more onerous water quality obligations.

Some might be grappling with previously overlooked discharges, such as a polluted groundwater plume that seeps into a wetland. Mines nearing closure also face increased water quality obligations as they cease dewatering and inundated open pits begin decanting to rivers.

“Whether a company is looking to meet stricter limits or improve the quality of its discharge, one of the first decisions it will need to make is usually related to possible treatment options for the water it discharges. This is where a broader approach is valuable, because few water treatment options are completely free of environmental impact,” Adams notes.

Treatment processes will successfully generate cleaner water, but most of these processes also produce by-products or side-effects that pose their own unique set of potential risks to the environment and surrounding communities.

Reverse osmosis, for example, is well accepted, not only for seawater desalination but also for the removal of salts and metals which are common pollutants in mining and industrial discharge waters. However, the reverse osmosis process emits carbon and produces brine. While there are defined processes for capturing and disposing of the residual brine, it is still a process that needs to be competently managed or it can become risky.

“Most treatment processes create waste but the practical reality is difficult to appreciate,” Adams says, citing the real-world example of 27 trucks being required each day to transport brine to a hazardous waste facility.

“For such large volumes, transporting offsite would be unlikely but that does not lessen the waste burden. Even if brine is concentrated by means of crystallisation, the process will emit carbon and still produce waste, albeit in lower volumes.”

On-site disposal facilities for brine, or other waste products, are an option – especially for remote sites – but these present their own set of problems. The waste is stored permanently, thereby sterilising a piece of land and presenting an ongoing risk of leakage, especially as the facility ages.

Adams says that, when considering treatment, the key question is whether the risk and impacts outweigh the benefits. Each case needs to be carefully assessed on its merits.

Given the downsides of many water treatment options, she says that companies should make sure that all other less problematic solutions are in place before turning to treatment. These alternatives might include additional source controls, such as further stormwater controls, which would prevent onsite water from becoming contaminated in the first place. Passive treatments, such as artificial wetlands, can also be considered.

If treatment is the only solution, then its unintended impacts need to be recognised.

These impacts could even form the basis for an amendment to the water quality limits contained in a water use licence – if the risk of the by-products to the environment, even with appropriate management in place, outweighs the risk of the untreated water or partially treated water being discharged to the natural water resource and downstream users.

“The aim of considering these broader aspects is not to reduce water quality limits by avoiding treatment through water use licence amendments, but rather to ensure that any proposed solution is optimal to the environment and society. This is in keeping with the Department of Water and Sanitation’s recent improvements to its water use licence application process,” Adams says.

To weigh up the impacts of treatment versus partial or no treatment, an options analysis is typically undertaken. An options analysis should incorporate nonwater impacts such as carbon emissions, waste disposal and site-specific quality limits.

“Some confirm treatment as the optimal solution and others lead to a combination of traditional treatment, passive treatment and a water use licence amendment application to request the easing of water quality limits. There is much learning along the way in an options analysis, and investigations frequently expose not only unexpected costs and complications, but also other opportunities – some of them perhaps potentially innovative,” Adams concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation