Calls to reuse water treatment waste take centre stage at WISA 2016

MEGAN SCHALKWYK Findings suggest that there has to be a change in mind-set across the water industry value chain, with stakeholders treating WTR as a reusable commodity rather than waste

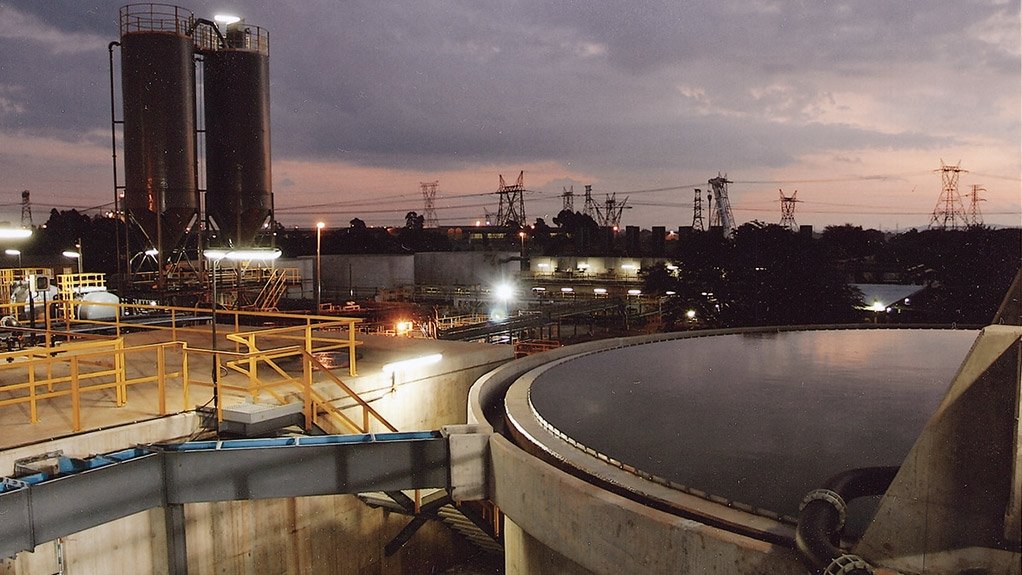

While the cost-effective and environmentally compliant disposal of water treatment residue (WTR) is a challenge for water treatment practitioners worldwide, WTR management has taken centre stage in the local water industry amid increasing water demands, deteriorating raw water quality aggravated by drought conditions and stricter legislation.

The problem has captured the interest of various stakeholders, including local water boards, municipalities, government and civil society, according to a research study, titled ‘Water Treatment Residue Handling, Disposal and Reuse: Developing a Management Strategy’, which KwaZulu-Natal bulk water supplier Umgeni Water process engineer Megan Schalkwyk presented at the Water Institute of South Africa biennial conference and exhibition, held at the Durban International Convention Centre earlier this month.

The research found that the trend is to replace WTR disposal with the concept of WTR reuse, she noted.

“WTR is the solid waste generated in the potable water treatment process and comprises clays, silts, algae and, to a lesser extent, trace metals and organics. Currently, WTR is considered by water utilities as an inert waste and has historically not been measured either qualitatively or quantitatively.”

She added that the Water Treatment Residue Handling project, which was initiated in April 2014 by Umgeni Water on behalf of the Water Research Commission, focused on conventional water treatment plants with capacities larger than 2 500 m3/d.

“The findings suggest that there has to be a change in mindset across the water industry value chain, with stakeholders treating WTR as a reusable commodity rather than waste. Its reusability might be site specific, depending on logistics, WTR characteristics and volumes,” Schalkwyk stated.

Legally, WTR was also considered waste, governed under the National Environmental Management Waste Act No 59 of 2008 (Waste Act). The Department of Environmental Affairs pro- mulgated new legislation in 2013, which placed new stringent regulations on the management of WTR, resulting in higher operational and capital costs for the management of wastewater sludge and drinking-water treatment residue.

She noted that Umgeni Water was reusing WTR from one water treatment plant as a soil conditioner at a farm owned by the company and sludge from its largest wastewater works as fertiliser for a turf-manufacturing company.

While 81 waterworks nationwide – including large-capacity water treatment plants in Gauteng, the Western Cape, the Northern Cape, KwaZulu-Natal, the North West and the Eastern Cape, along with six water boards, one metro and three district municipalities – formed part of the sample, it was noted that the majority of water treatment works were storing their WTR on site.

“Landfills were still the most popular disposal method for large and medium-sized water works at the time of the site visits.

“Only 47% of the water treatment works in the sample set were disposing their sludge in accordance with the regulations stipulated in the Water Act No 36 of 1998 and the Waste Act,” she pointed out.

Schalkwyk’s research noted incapacity and resources as reasons for keeping abreast of the changing South African legislation. Further, as there were no guidelines to assist in reusing and disposing WTR, companies remained unsure of how to handle the waste. She also added that these companies did not clearly understand the criteria for compliance standards.

“The blanket extension of chemical waste standards to WTR compliance requirements was a bone of contention for most water treatment practitioners, who were, therefore, less sensitised to the importance of legislative compliance. Some of the water service providers and water service authorities were struggling to maintain the legislated standard for the potable water they produced, so WTR management was secondary to the larger water treatment problems they faced.”

Management

As part of the study, Schalkwyk suggested an integrated WTR management system, as it took into account the impact of WTR across the whole water chain.

While a WTR management system could be advantageous to several role-players in the water sector, Schalkwyk said there was a fair amount of apathy locally regarding WTR management, judging by the small percentage of water suppliers actually investigating management strategies.

“Companies can save if WTR is viewed as a by-product and not a waste. If waterworks are designed for potable water production and to reduce WTR, while ensuring a physically and chemically consistent, higher-value WTR, then WTR management will become sustainable,” she stated.

She noted that the South African legislation pertaining to WTR disposal, recycling and reuse was not clear or well understood by water treatment practitioners, with more influence needed from important stakeholders in the sector.

“Water treatment practitioners should be more proactive in the setting of WTR disposal standards and play a more influential role in advising legislators before promulgation of WTR-related legislation,” Schalkwyk concluded.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation