Chute systems ensure reduced dust and increased productivity on mine

Custom engineered chute systems have been installed at Zimbabwe mine Zimplats, and are said to have significantly reduced dust levels while increasing productivity at the mining operation.

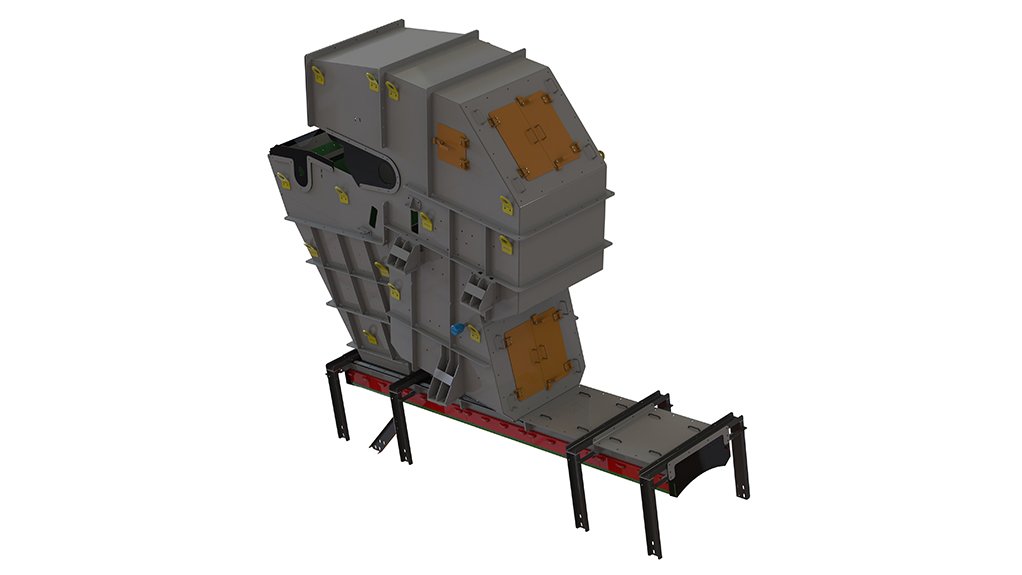

Weba Chute Systems’ tailormade installations are used for a range of applications including conveyor onto conveyor transfer chutes, apron feeder discharge chutes, mill feed chutes, conveyor onto bins transfer chutes, screen over and under size chutes, silo chutes, and transfer chutes at the crushing and screening stations.

The company recently secured another contract to provide ten custom-engineered transfer chutes for the expansion of an underground crusher station at Zimplats.

Weba Chute Systems project manager Ted Cruikshank says that these chutes will handle the transportation of run-of-mine material from the ore pass to the underground crusher and from the crusher to the outgoing conveyor. He says the engineering and construction of these chutes will ensure a fit-for-purpose robust solution with the height of the chutes ranging from two to six metres.

Cruikshank explains that the chutes before the crusher are designed to manage large material up to 650 mm in size from a vibrating feeder, with a maximum tonnage of 1 100 t/h. “Other chutes will transport the feeder's undersize, less than 180 mm in size, at 550 t/h, while still others will be employed in conveyor-to-conveyor applications, feeding 1 500-mm-wide belts with up to 1 350 t/h of material and a maximum lump size of 250 mm.”

The company notes that its chute design philosophy, based on the cascade system, extends the wear life of the chute through the strategic placement of dead boxes, creating a layer of ore for the moving material to flow over. Replaceable lips are incorporated on the dead boxes to facilitate easy and quick swap-out at the necessary intervals. Accessible inspection doors also facilitate ease of maintenance. The design is said to be particularly effective in reducing dust levels.

Hilmax, Weba Chute Systems' local agent in Zimbabwe, will oversee the chute installations and provide spare sets of wearing lip liners for each chute.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation