Dezzi and Booyco Engineering tackle heat and dust head-on

To meet increasingly stringent health and safety standards, Dezzi Equipment has partnered with Booyco Engineering to equip its machines with customised HVAC systems

Each Booyco Engineering air conditioner fitted to Dezzi Equipment is manufactured to ISO 5151 T3 standards, ensuring reliable cooling in ambient temperatures up to 46°C and beyond

Manufactured in South Africa, Booyco Engineering’s bespoke HVAC systems are designed to meet the exact specifications of Dezzi Equipment’s mining and industrial machines

Built for the toughest conditions, Booyco Engineering’s locally manufactured HVAC units deliver consistent cooling for Dezzi Equipment’s machines on mines and construction sites

Booyco Engineering manufactures each HVAC system to the highest quality standards, ensuring long term reliability in the toughest working environments

Precision engineering and stringent quality control define every Booyco HVAC unit, from design through to final assembly

Each Booyco Engineering air conditioner is built with premium materials and robust components to withstand extreme heat, dust, and vibration

Booyco Engineering’s ISO-certified manufacturing processes guarantee HVAC systems that consistently deliver exceptional performance in demanding applications

This article has been supplied.

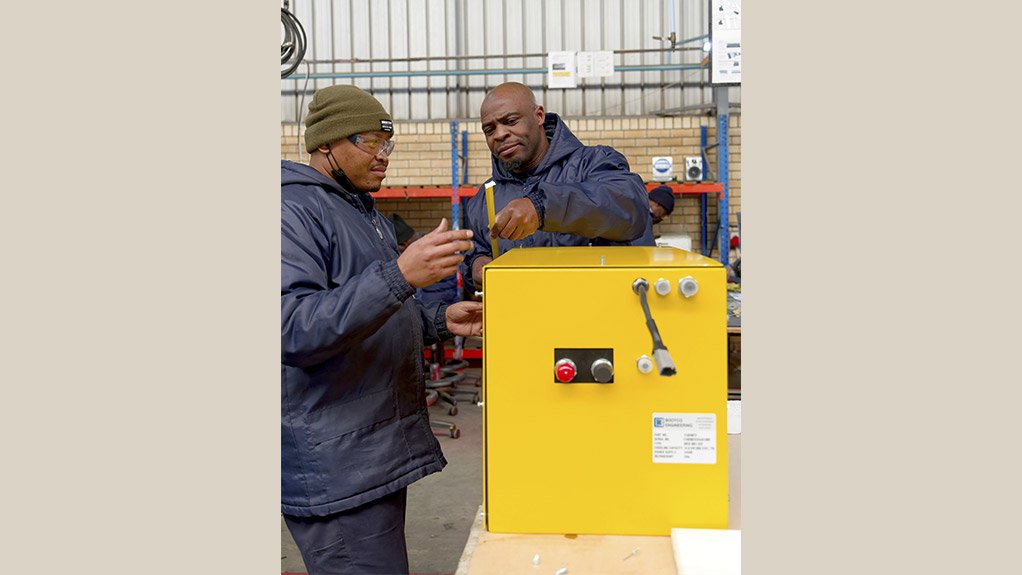

As health and safety standards in mining and related industries become increasingly stringent, heavy equipment manufacturer Dezzi Equipment is ensuring compliance by equipping its machines with customised HVAC systems from Booyco Engineering - engineered to meet the demanding requirements of end-users.

According to Gordon Postma, Sales Manager at Booyco Engineering, the two South African companies have collaborated since 2023 to develop bespoke HVAC solutions tailored to Dezzi Equipment’s customer needs. Operating from a factory in Port Shepstone with over 120 employees, Dezzi Equipment manufactures mobile machinery for the sugar, forestry, construction and mining sectors. The company supports its equipment through 20 branches across South Africa and a network of dealers throughout Africa.

With over 40 years of experience in specialised HVAC systems for mobile applications, Booyco Engineering customises its standard units to meet the specific requirements of individual customers and operating conditions.

“Dezzi Equipment was seeking a reliable local supplier with both design and manufacturing capabilities to deliver a bespoke rooftop HVAC system capable of withstanding the harsh conditions on their customers’ work sites,” says Postma. “The systems we supplied were engineered to perform in extremely hot environments with high dust levels, while also offering resistance to vibration and protection against debris that could cause damage.”

Postma notes that Dezzi Equipment frequently supplies machines to the mining sector, where stringent health and safety standards require a comfortable and controlled working environment for operators. In hot and dusty conditions, an effective HVAC system is essential to maintaining safe and comfortable conditions inside the operator’s cab.

“Modern standards and legislation allow operators to stop work if the HVAC system fails to function effectively, as cab temperatures can become dangerously high on many surface mining sites,” Postma explains. “This is why Dezzi Equipment turned to us to develop a solution that not only delivers high performance, but also ensures reliability to minimise unplanned downtime and maintain productivity.”

The collaboration to develop a bespoke HVAC solution for a specific vehicle began in early 2023, with the first prototypes designed and delivered by July that same year.

“In one overseas application, Dezzi Equipment’s machines were operating in ambient daytime temperatures exceeding 50°C,” says Postma. “We customised our standard units to ensure they could deliver the required performance and reliability when operating in these extreme environments.”

Booyco Engineering also adapted its HVAC design to suit an application where heavy mobile machinery was operating at low engine speed, ensuring effective performance even under reduced power conditions.

“Our air conditioning systems are ISO 5151 T3-rated, meaning they are designed to operate in ambient temperatures of at least 46°C unlike many competitor systems which are ISO 5151 T1-rated for just 35°C,” says Postma. “This higher rating ensures our products maintain the specified performance in extremely demanding environments.”

Postma notes that Booyco Engineering’s customisable HVAC systems can now be fitted to 90% of Dezzi Equipment’s machine range, with different versions available to suit specific applications. Key customisations include the removal of heating functionality on some versions and vehicle specific refrigerant hose kits to meet the unique requirements of each machine model and operating environment.

“The initial system we supplied to Dezzi Equipment was a 24-volt unit that provided both heating and cooling,” says Postma. “Over the course of our collaboration, we have expanded the range to include 12-volt versions, cooling-only versions and systems specifically designed for high ambient temperature applications.”

Explaining the value of Booyco Engineering’s bespoke solutions, Shane Gutzeit, Dezzi Equipment’s Director for After Sales and Technical, says :“Partnering with a local specialist like Booyco Engineering allows us to offer our customers robust reliable HVAC systems that are purpose-built for tough working environments. Their ability to customise and respond quickly to our needs ensures we can maintain high equipment availability and meet the operational demands of our clients across various industries.”

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation