Fit-for-purpose components ensure safety, high performance

DIVERSE APPLICATIONS Tsubaki backstop cam clutches are suitable for contamination-free processes, high temperature environments and wet, corrosive and dusty conditions

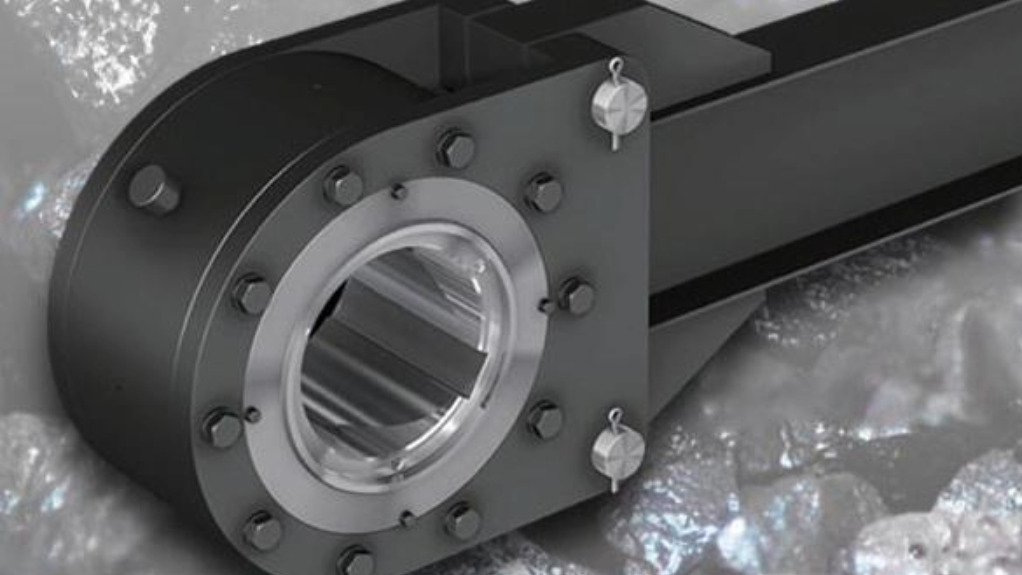

CUSTOMISED DESIGN BMG's wide range of Tsubaki reclaimer chains are designed and manufactured with various options to suit specific requirements of the coal mining sector

To maintain critical safety standards and adhere to current legislation, industrial equipment supplier BMG works closely with engineers in the coal mining sector to select products suited to their intended application, says BMG Power Transmission division business unit manager Carlo Beukes.

The Mine Health and Safety Act requires that incline conveyor belts must be fitted with, and use, one or more devices to prevent run-back or run-on, to prevent injury by materials or minerals falling from a conveyor belt, he explains.

BMG’s range of back stop cam clutches, manufactured by power transmission products specialist Tsubaki, prevents reverse rotation of incline conveyors, offering a simple and cost-effective measure to protect capital equipment and enhance safety onsite.

The Tsubaki range is available with different capacities and designs, to provide optimal functional characteristics for three basic modes of operation: over-running, indexing and backstopping.

“Our technical experts advise mines on the selection of the correct cam clutch for each application and appropriate installation and usage, for optimum performance and safety at every mine,” says Beukes.

BMG’s range of Tsubaki backstop cam clutches, which is suitable for high or low speed applications, meets the requirements of current mining legislation and has several advanced features not found in conventional models, he elaborates.

In particular, the high-torque, high-speed Tsubaki BS-F series is well-suited for coal mining applications as the series is designed for high-speed inclined and long overland belt conveyors as well as bucket elevators.

Beukes explains that the BS-F series’ narrow-width I-beam torque arm is a drop-in replacement to conventional roller-ramp designed devices, allowing for quick and easy onsite installation.

Its design also enables quick replacement of an old backstop with the new BS-F design, without modifying the existing layout.

Despite the series having a narrower width than other models, the downsized unit exceeds the requirements of high-speed inclined belt conveyors, while offering space-saving and reduced installation time benefits.

Beukes notes that a common cause of conventional backstop failure is oil leakage – a risk Tsubaki has eliminated in the BS-F series by designing the backstop to operate with grease and a specially-designed labyrinth seal.

Other features of this series include a non-rollover cam and roller design, which offers higher backstop torque capacities and lower running temperatures than conventional anti-rollback devices.

In addition, its flexible labyrinth seal mechanism prevents the ingress of dust and water in abrasive conditions while its double-lip oil seal and multi-temperature grease enable safe operation across a wide ambient temperature range of -40 oC to 65 oC.

The cam and roller cage orbit at low speed, continually conveying grease internally from the bottom to the top of the mechanism, reducing internal friction and lowering operating temperature for “dependable operation”, says Beukes.

Maintenance intervals are between 7 500 hours and 8 000 hours and the effective service life of the units is also significantly extended compared with conventional oil-filled units, he adds.

Careful Care

For extended service life, Beukes emphasises the importance of correct lubrication methods and dust prevention care.

For easy and effective maintenance of the BS-F series, BMG recommends the use of a maintenance kit and Tsubaki-approved EP-free grease.

The company offers customers a complimentary Tsubaki maintenance kit with BS-F backstops larger than a 200 mm shaft, allowing for easy servicing of the unit during operation, without the need for removal from the shaft.

BMG also supplies a wide range of customised Tsubaki reclaimer chains, designed and manufactured with various options, to suit specific requirements of reclaimers used in the coal mining sector.

To provide optimum performance and achieve the best overall value, Beukes explains that reclaimer chains must have big bearing areas, high hardness and deep case depth.

Tsubaki engineers have implemented these principles while retrofitting many reclaiming conveyors with chain and sprockets, resulting in longer service life than original equipment manufacturer chains.

Owing to their complex requirements, Beukes says reclaimer chains are manufactured on a made-to-order basis and are designed and manufactured to meet the specific, unique requirements of each site.

Tsubaki has developed new reclaimer chains with outboard rollers that prevent the build-up of abrasive particles between bushes and rollers, mitigating premature wear.

Further, Tsubaki’s improved labyrinth seal construction has enhanced anti-dust capabilities, preventing debris from infiltrating the outboard rollers and chain wear areas, while the outboard rollers are permanently sealed and require no additional maintenance.

Tsubaki’s customisable large size conveyor chains are also available from BMG, with a selection of base materials, corrosion-resistant coatings, attachments and rollers.

BMG’s national branch network, which provides both technical advisory services and 24-hour backup support, stocks a wide variety of the Tsubaki products locally.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation