Fully electric anode weighing and casting machine improves accuracy and performance

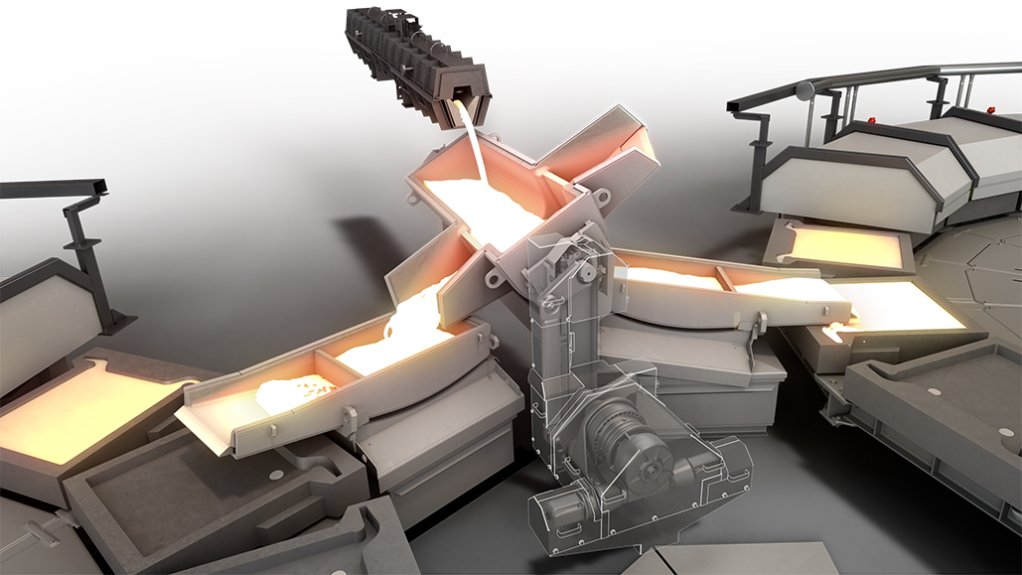

A new solution aimed at addressing the needs of the copper processing industry uses the latest Outotec casting control system with self-diagnostic and machine intelligence capabilities to help provide superior casting accuracy, performance and ease-of-use. The fully electric anode weighing and casting machine was recently launched by Metso.

For copper electrolysis, it is vital that the copper anodes received from the anode casting shop are uniform in size and weight. This contributes to high performance of the electrorefining process and high-quality cathode production, explained Metso director: anode casting Sami Maaniittu.

“The new fully electric Anode Weighing and Casting Machine, combined with the latest casting control system, is a perfect choice when you want the best casting accuracy for the anode casting shop,” says Maaniittu.

The casting machine uses servo motors that enable precise movement control in the tilting processes of the casting machine. The process is energy efficient, as the servo motors operate with electricity, and when the motors are braking, the braking energy is returned to the grid. The servo motors also support the safety features of the equipment. In case of an electrical blackout, the system has capacitors to feed the necessary energy to the servo drives to level the casting ladles to a horizontal position to prevent copper overflow.

An advantage of using an electric servo system instead of a hydraulic system is ease of installation, as the operator requires only power and a signal cable for the servo motor. There are no flammable hydraulic fluids, which improves safety in cases of molten copper spills on the cables. In addition, cables can be replaced quickly and easily and the reduced number of moving parts helps facilitate ease of maintenance.

The new casting control system includes a user-friendly human-machine interface which has been upgraded to be more intuitive and easy to use.

The anode casting equipment is also modular, enabling incremental upgrades. The new casting control system works with the old Outotec hydraulic casting machines, and as a combined package with the latest casting machine.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation