Gas turbine gensets generate power and produce useful exhaust gas

Gas turbine generator sets (gensets) designed to deliver energy solutions that reduce a company’s reliance on power utilities, have the added benefit of being able to capture the high temperature exhaust gas and use it for a range of heating applications within a factory.

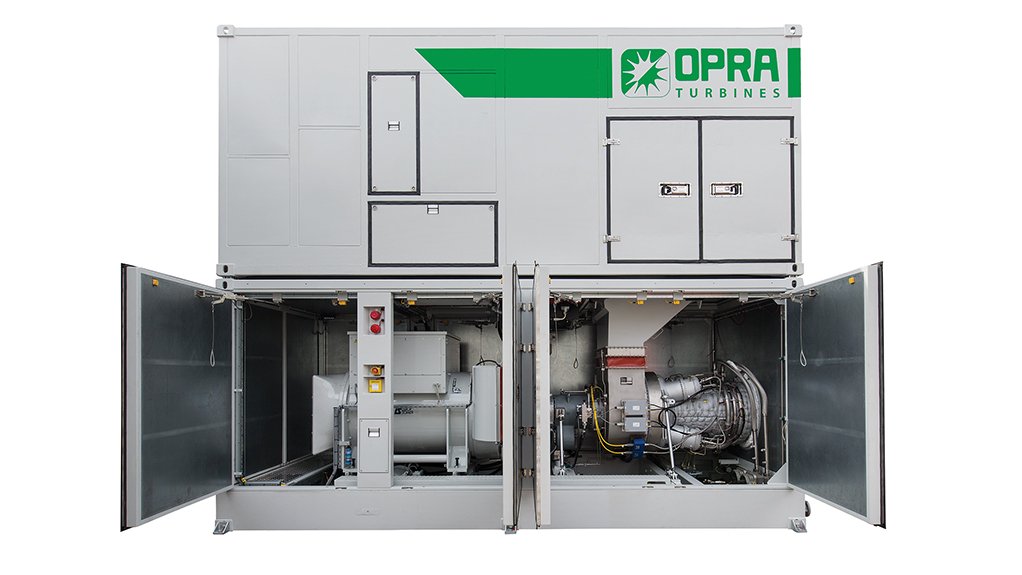

The 1.8 MW OP16 gas turbine manufactured by Opra Turbines is said to deliver high fuel flexibility, a small footprint and long operating hours between major overhauls. It has a robust, industrial, all radial design and can deliver energy solutions using a variety of fuel sources, states the company.

In addition, the turbine’s high temperature exhaust gas, measuring 573 ℃, can be captured and used for process heating purposes.

Kirton Mechanical Equipment has partnered with Netherlands-based manufacturer OPRA Turbines and Swiss-based Enerproject Gas Solutions to offer the comprehensive energy solution.

The two main uses of the OP16 gas turbo genset are:

- Generating 8 MW of power to provide energy to a plant

- Generating valuable high temperature exhaust gas which can be used for a variety of applications

OPRA turbines are used in a number of sectors, such as:

- Oil and gas - used for the recuperation of associated gas, as stand-by emergency units, thermal enhanced oil recovery systems and other processes

- Waste to power - for the combustion of syngas from different types of feedstock and the combustion of pyrolysis oil from plastic wastes

- Industrial and commercial – such as paper mills, tobacco, rubber plants, ceramics, gypsum and breweries, amongst others

- Marine - destruction of volatile organic compounds from shuttle tanks, cold ironing applications, stand-by emergency units and various other uses

The OP16 gas turbine genset is suitable for a range of fuels with high and low calorific values, as well as liquid fuels. It can be operated on a dual fuel principle, simultaneously or switched while on full load. These include natural gas, flare gas, propane, liquefied petroleum gas, syngas, biogas, industrial waste gas, diesel, pyrolysis oil, ethanol and condensate. End-users may have a by-product that can then be used as fuel, or converted to fuel, for the gas turbine.

The high exhaust gas temperature has thermodynamic value for a number of applications such as heating for boilers, spray dryers, heating kilns and general drying processes.

To operate efficiently, the turbine requires inlet gas pressures of 11 bar G to 16 bar G, which necessitates the inclusion of a fuel gas booster compressor, where low pressure gas is the fuel. Enerprojects Gas Compressor Solutions facilitates the inclusion of suitably sized oil injected rotary screw gas booster compressors or reciprocating packaged units, where required.

Enerprojects Gas Solutions also offers skid mounted technology which can be used to capture flare gas and process it through solid + liquid scrubbers, a compression cycle, a drying cycle and a regenerative heating cycle, after which the gas can be compressed to fuel the OPRA OP16 turbine genset, or for other applications.

Application of this flare gas process offers end-users a partial solution to problematic carbon dioxide emissions during flaring.

Where flare gas is available, a solution is offered which includes utilisation of the flare gas as fuel, generation of power and high temperature exhaust gas for processes. This aims to close the loop for in-house power generation in this category.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation