HDPE pipe manufacturing facility to open in February

NOT A PIPE DREAM DPI's new facility will enable it to supply pipes to South Africa's burgeoning gas market

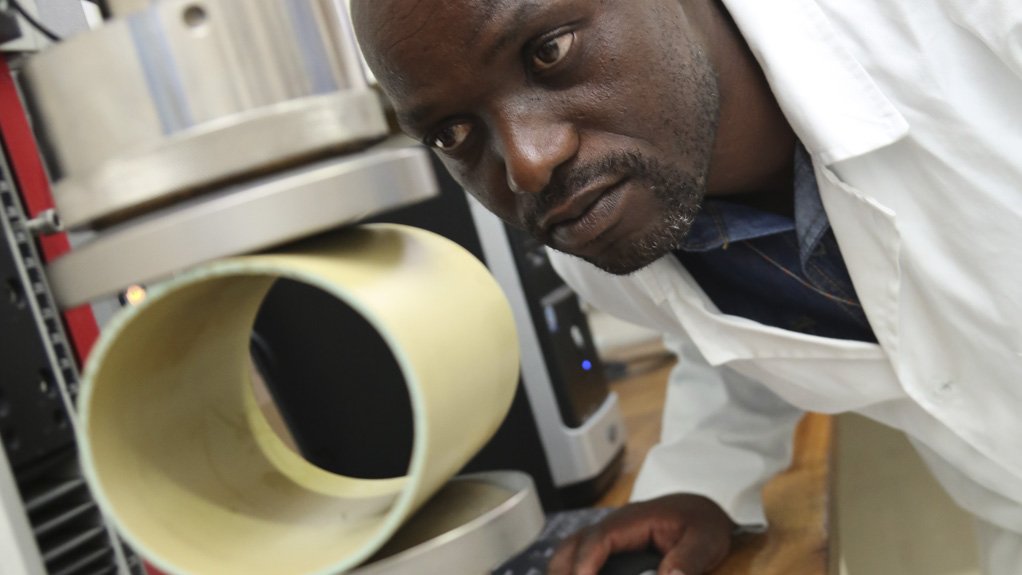

Plastic pipes manufacturer DPI Plastics will launch its new Germiston-based manufacturing facility in February. The facility will manufacture high-density polyethylene (HDPE) pipes from 16 mm to 1 000 mm in diameter.

DPI technical and product manager Renier Snyman says the facility will enable DPI to become a major player in the South African HDPE market, specifically in terms of supplying the burgeoning gas market.

“We will be able to provide HDPE pipes for gas transport in addition to the pipes we already supply for water infrastructure purposes.”

He points out that the South African government has earmarked the gas industry as a potential driver of economic growth, noting that the Department of Trade and Industry (DTI) and the South African National Energy Association developed a conceptual framework last year for a natural gas industrialisation strategy and established the DTI-led Gas Industrialisation Unit.

Snyman adds that government’s efforts to establish an effective gas sector will present opportunities for manufacturers hoping to supply equipment and goods for the establishment of gas pipelines. He comments that, while this will be a new market for the company, DPI and its sister companies in Namibia and Mauritius will be able to provide a complete solution for HDPE pipe systems, including pipes, fittings and fabricated specials.

Further, he states that there are only a few other companies in South Africa that can offer this range of products. This ensures that DPI is well positioned for future growth, particularly in view of government’s emphasis on using local suppliers for procurement.

The HDPE pipes will be manufactured to ISO 4437 requirements, which specify the general properties of polyethylene compounds for the manufacture of pipes and fittings intended to be used for the supply of gaseous fuels. It also specifies the test parameters for the test methods to be used. Moreover, DPI will use the facility to add to its current manufacture of HDPE pipes for water and civil solutions.

Snyman adds that DPI will apply for approval from industrial certification provider South African Technical Auditing Service (Satas) once the new facility is operational.

Industry Overview

DPI MD Juan Muller notes that there has been a decline in major civil works projects that require large-bore polyvinyl chloride (PVC) pipes, compared with similar projects in 2015.

“However, DPI has quoted about R800-million worth of PVC tenders for water infrastructure, which we expect will start in February or March.”

Snyman comments that, while DPI has managed to retain and secure new work, there are still numerous challenges facing the local pipe-manufacturing industry. He cites as a major concern the problem of companies retaining their South African Bureau of Standards (SABS) certification owing to the SABS’s lack of capacity to test and certify products.

“Satas has been identified as a viable alternative, and a number of manufacturers are considering Satas certification,” Snyman says, adding that, regardless, the current inefficacy at the national standards authority needs to be addressed.

He also notes that the country’s poor economic performance has resulted in a reduction in construction and civil work, which has impacted on growth in the plastic pipes industry. Further, the country’s economic outlook is expected to remain subdued in the short to medium term and, hence, a recovery for the industry is improbable.

Finally, Snyman notes that, even when civil work is completed, delayed payment from municipalities impacts on businesses’ cash flow, which, in turn, adversely affects the effectiveness of operations.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation