How elastomeric couplings drive mining efficiency

SUPPORTING RELIABILITY Couplings play a vital role throughout mining operations, transferring torque between rotating shafts while compensating for angular, parallel or axial misalignment

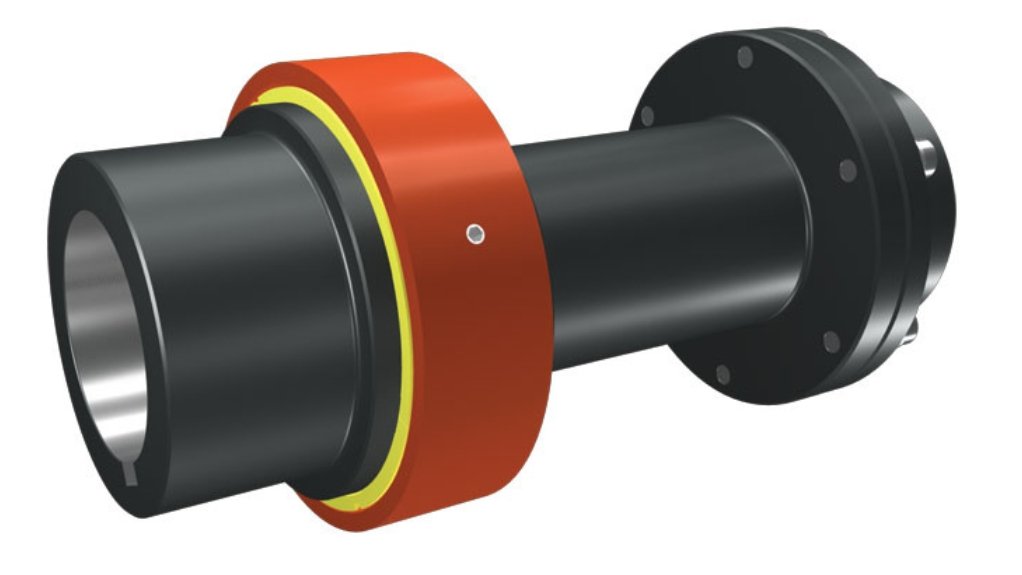

A SERIES SUPPORT The elastomeric coupling’s flexible element absorbs shock and torsional loads, helping to maintain smooth torque transmission and extending the life of surrounding equipment

SUPPORTING RELIABILITY Couplings play a vital role throughout mining operations, transferring torque between rotating shafts while compensating for angular, parallel or axial misalignment

The mining industry relies on equipment that operates under extreme stress, encompassing heavy loads, shock vibration, abrasive dust and unpredictable conditions. Every component in that system must deliver consistent performance, yet few play as critical a role as the coupling. Often overlooked, the coupling is what keeps the drivetrain moving smoothly, absorbing misalignment, reducing shock loads and protecting high-value rotating assets from premature failure, says mechanical seals and support systems supplier John Crane.

Couplings play a vital role throughout mining operations, transferring torque between rotating shafts while compensating for angular, parallel or axial misalignment. In doing so, they safeguard bearings, mechanical seals and other connected components from destructive mechanical forces.

Elastomeric couplings are particularly well-suited to mining applications because they use a flexible element, typically rubber or polyurethane, to absorb vibration and torsional shock. This flexibility cushions connected machinery against sudden torque spikes and accommodates minor shaft misalignment that inevitably develops as equipment settles or wears. In environments where downtime can cost millions, resilience is essential.

Managing Misalignment and Shock Loads

Misalignment is unavoidable in large-scale mining plants, says John Crane. Ground movement, thermal expansion, uneven foundations and bearing wear all contribute to shafts falling out of perfect alignment. A rigid connection between misaligned shafts increases stress, which can lead to bearing damage and shaft fatigue.

“Elastomeric couplings counter that by flexing under load. Their resilient element deforms slightly to absorb angular or parallel offset, maintaining torque transmission without transferring harmful loads downstream.”

In processes such as crushing or grinding, where machines start and stop under high torque, the ability to dampen shock loads is equally important, adds the company, explaining that elastomeric elements act like a buffer, reducing peak torque and smoothing power transfer to protect gearboxes and motors.

Together, these capabilities ensure smoother operation and improved reliability across demanding process stages.

Supporting Reliability in Demanding Applications

Mining operations run continuously, often in remote areas where maintenance resources are limited. Elastomeric couplings contribute to reliability through their simple, maintenance-free design. With no lubrication requirement and minimal moving parts, they eliminate one of the common causes of coupling failure – improper greasing. Their ability to tolerate vibration and misalignment reduces stress on adjacent equipment, allowing operators to extend maintenance intervals.

“In extraction systems, they handle high-torque conveyors and crushers that endure constant impact from mined rock. In milling and grinding, they isolate drives from vibration and torsional oscillations generated by large rotating drums. Refining circuits rely on them for consistent torque transmission under varying thermal and chemical conditions, while dewatering pumps benefit from their damping properties, which reduce shaft movement and bearing wear,” elaborates John Crane.

Reducing Downtime and Operating Costs

Every unplanned stoppage in a mine affects production output, maintenance budgets and safety. Elastomeric couplings reduce these risks by preventing the chain reaction of failures that can begin with a misaligned shaft. When combined with a predictive maintenance programme, their performance characteristics –temperature, torque and vibration – can even serve as indicators of developing system issues.

Because the elastomeric element is inexpensive and easy to replace, maintenance can often be completed on-site without requiring the removal of connected equipment, says John Crane. Other operational benefits include shorter repair time and simplified maintenance procedures; no lubrication, reducing consumable costs and contamination risk; increased equipment uptime; and lower total cost of ownership.

By simplifying maintenance and lowering lifecycle costs, elastomeric couplings directly support higher productivity and safer operations, notes the company.

Aligning with Sustainability Goals

Energy efficiency and sustainability have become strategic priorities across Africa’s mining sector. By reducing vibration and mechanical losses, elastomeric couplings can help improve drivetrain efficiency and contribute to lower power consumption. Their ability to extend equipment life and reduce the frequency of parts replacement also supports waste-reduction targets and responsible resource use, which are both increasingly essential metrics in the global mining supply chain, says John Crane.

“Their maintenance-free design also eliminates the need for lubricants, helping operators reduce the use of consumables and limit the environmental risks associated with oil handling.”

A Proven Choice

In mining, reliability comes from well-engineered components that perform under pressure. Elastomeric couplings play a vital role in protecting connected equipment, reducing vibration and compensating for misalignment across extraction, grinding, refining and dewatering operations.

John Crane’s A Series elastomeric coupling is built for these conditions. Its flexible element absorbs shock and torsional loads, helping to maintain smooth torque transmission and extend the life of surrounding equipment. The coupling’s simple, maintenance-free design reduces downtime, while its durable materials withstand the high torque and harsh environments typical of mining.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation