Hydrogen economy poised as key booster for platinum group metals – Heraeus

Heraeus Precious Metals New Business Development EVP Dr Philipp Walter interviewed by Mining Weekly’s Martin Creamer. Video: Darlene Creamer.

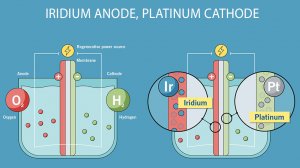

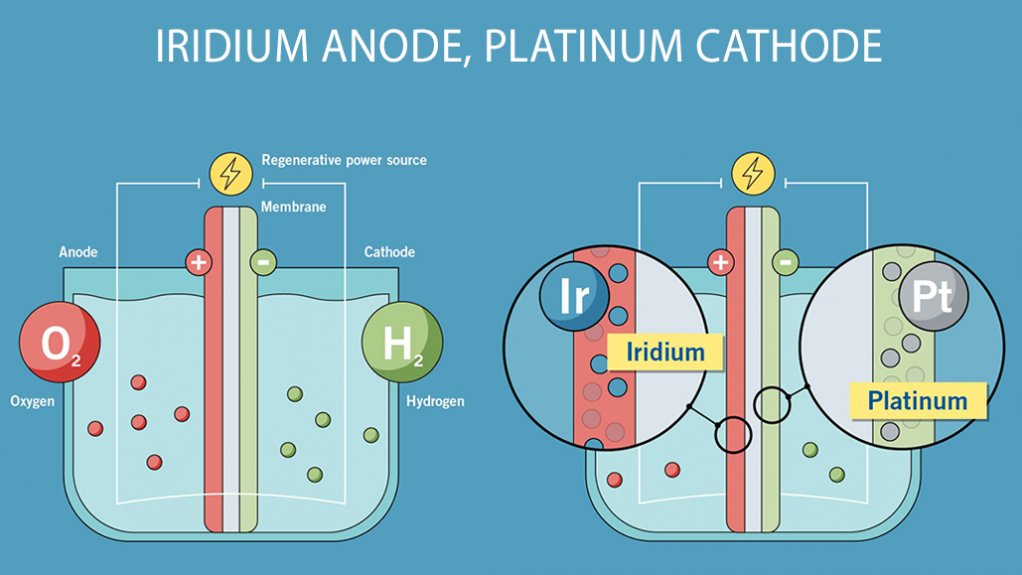

To enable oxygen reaction, anode of PEM electrolyser is iridium-coated and cathode platinum-coated.

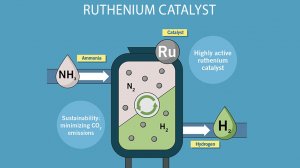

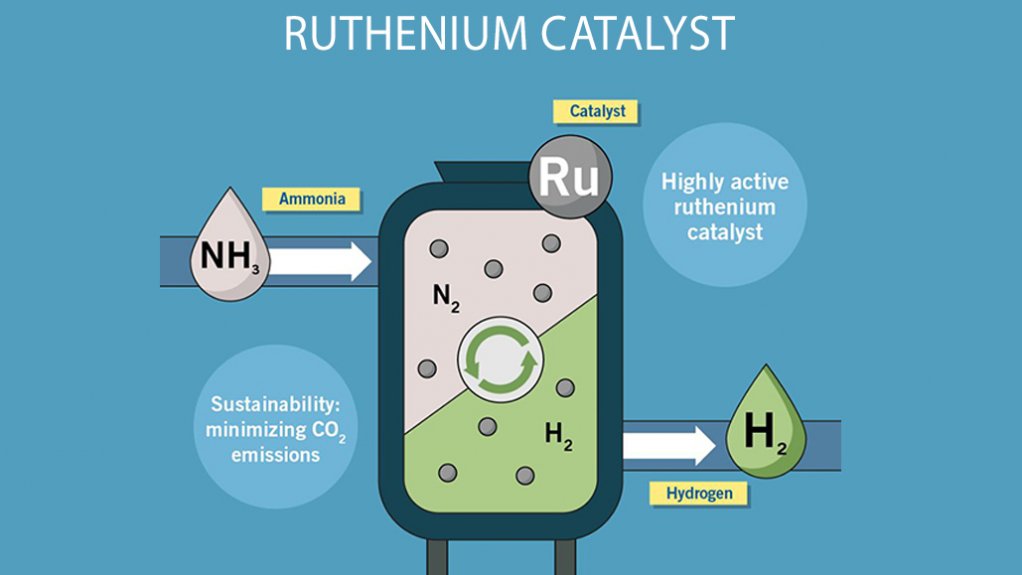

Ruthenium catalyst regains hydrogen stored in ammonia.

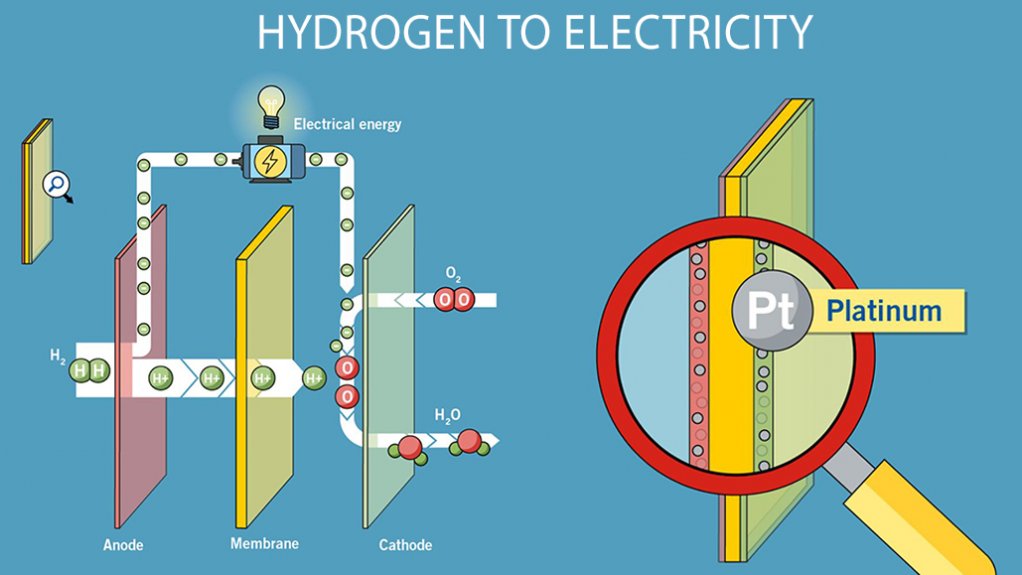

Platinum cathode required in PEM fuel cells to convert hydrogen to electricity.

Hydrogen economy cannot do without PGMs.

The hydrogen economy is an important new growth area for platinum group metals (PGMs) and, in turn, PGMs are pivotal for hydrogen production and application across a broad front.

Accentuating this in a Zoom interview with Engineering News & Mining Weekly, Heraeus Precious Metals new business development executive VP Dr Philipp Walter highlighted the strong global current momentum of the hydrogen economy – “politically, socially and technologically”.

“There’ll be significant growth,” Walter forecast shortly before departing for Asia to visit customers.

To meet that growth, Heraeus Precious Metals has formed its new Business Line Hydrogen Systems unit to focus on hydrogen applications, in particular proton exchange membrane (PEM) electrolysis and fuel cells, as well as the recycling of spent electrolysers and membranes.

“When I started in this role five years ago, now and thenthere was an article about hydrogen and PEM electrolysis, but nowadays, these are skyrocketing,” he noted.

Amid the need to replace the anticipated potential loss of PGMs demand to battery electric vehicles, hydrogen is seen as providing abundant opportunity to replace expected PGMs demand loss.

The hydrogen-related applications in which PGMs play a key role may begin with green hydrogen using PEM electrolysis but they certainly do not end there, extending as they do to other elements in PEM electrolysers, and so much more beyond that.

PGMs, for example, are again key in the transport of hydrogen through carriers such as liquid organic hydrogen carriers, or LOHC, ammonia, methanol and fuel cells. The European Clean Hydrogen Alliance has just published the Learnbook on hydrogen imports into the EU market, citing LOHC technology as a viable hydrogen transport solution. LOHC can use existing non-cryogenic liquid fuel infrastructure at ports, thus transforming assets without leaving stranded investments.

Green hydrogen depends on especially PEM electrolysis technology owing to this coping best with renewable energy fluctuations.

In addition, platinum, iridium and now also ruthenium play electrocatalytic roles in splitting water into hydrogen and oxygen, with PGMs also being used as catalysts to crack ammonia into nitrogen and hydrogen and to convert carbon dioxide into methanol or other hydrogen-carrier molecules.

Furthermore, PGM catalysts are essential in gas purification through palladium membranes, by either removing oxygen in a hydrogen stream or removing hydrogen in an oxygen stream.

In fuel cells, platinum on carbon catalysts are used to generate energy out of hydrogen and oxygen, forming water.

When hydrogen is converted into electricity by fuel cells, platinum allows the energy to be released in a controlled manner as mobile and stationary power, which is so useful in areas not served by national electricity grids.

The essential need to have enough iridium available to accommodate and accompany PEM electrolysis growth is already being met by highly successful thrifting achievements as well as through the addition of ruthenium.

This not only reduces reliance on iridium, a highly scarce and expensive PGM, but also reduces material cost.

Primary production of ruthenium, also a PGM, is three-and-a-half times greater than the primary production of iridium.

While some are seeking to substitute PGMs completely, being able to do so effectively is seen as highly unlikely.

“As a chemist, I find that difficult because I believe platinum group metals and hydrogen belong together, simply because of their chemical nature,” was Walter’s comment on the issue of substitution.

“Everybody dealing with platinum group metals also knows that thrifting is part of the DNA of platinum group metals,” he added.

Significant thrifting has not only been achieved with environmental catalysts, but also with autocatalysts, which have been reducing vehicle pollution for decades, as well as across many other applications.

“That’s what the industry is working on heavily, to basically allow for thrifting and to allow for accommodating the growth of PEM electrolysis and the growth of hydrogen,” said Walter.

Heraeus Precious Metals is a key player in the field of electrocatalysts for PEM electrolysis.

“We’re heavily involved in designing iridium- based electrocatalysts and now also iridium/ruthenium electrocatalysts for PEM electrolysis, with up to 90% less iridium loading compared with other solutions.

“The second element is recycling. It will not help the scaling-up mode because it’s an end-of-life topic, but recycling has to be in place and that is a huge advantage of platinum group metals over other metals. There is actually already a globally existing recycling infrastructure in place, which will help every industrialisation,” Walter outlined.

Hydrogen and South Africa

It has been estimated that the hydrogen economy has the potential to add 3.6% to South Africa’s gross domestic product (GDP) by 2050, along with 370 000 jobs.

South Africa is already acting with purpose to harness the potential of green hydrogen and if investment is significantly scaled up, green hydrogen can deliver the equivalent of more than one-third of Africa’s current energy consumption, increase the collective GDP, improve clean energy supply and empower communities.

Southern Africa already has 33 green hydrogen-linked projects charted, 26 of them in eight provinces in South Africa and seven in Namibia.

Southern Africa has world-class conditions for generating renewable energy through solar and wind power, which are key drivers of the production of green hydrogen, and innovative financing structures, sourced from multiple stakeholders, are available for green hydrogen projects that collectively can provide energy independence and export opportunities.

To date, the largest public finance commitment to South Africa’s green hydrogen sector is the Just Energy Transition Partnership (JETP). Conceived as an $8.5-billion multi- donor agreement, the JETP is a novel climate finance programme to deliver a just transition to affected groups.

Through its green ammonia export project in South Africa’s Eastern Cape, the leadership of Hive Hydrogen South Africa intends to show how a just energy transition is possible, Hive Hydrogen chairperson Thulani Gcabashe highlighted at last month’s signing ceremony of the $5.8-billion Coega green hydrogen and green ammonia development.

Hive Hydrogen South Africa and Itochu Corporation of Japan have signed a memorandum of cooperation to advance Hive’s Coega green ammonia export project and have agreed to work together on matters of viable green hydrogen and ammonia project development, production, operation, marketing, offtake and distribution.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation