Jib crane to be used for underground ore recovery

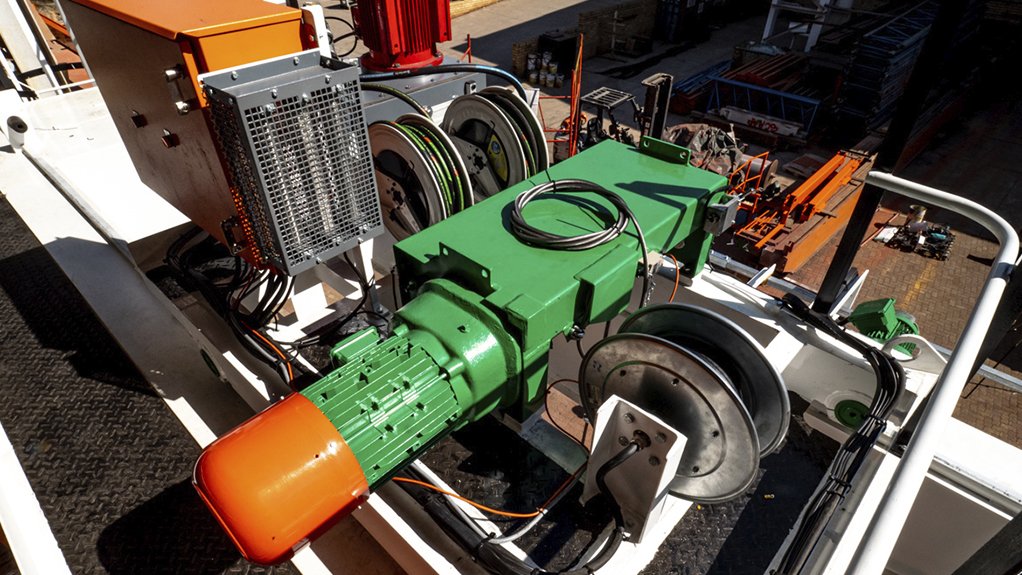

CRAB ASSEMBLY The assembled crab at the top of the jib crane, with the 5-ton hoist itself, hydraulic power pack, two hydraulic hose reels for the five-tine orange-peel grab, and the cable-reeling drum serving the electromagnet

JIB CRANE The 5 t job crane at Condra's factory before being delivered

Crane and hoist manufacturer Condra Cranes has designed, manufactured and delivered a large jib crane that will be trialled for the bulk recovery of ore spilled underground.

The 5 t crane has a 9 m lifting height and a slewing radius of 5 m, with an orange-peel hydraulic grab and electromagnet – a combination that allows for bulk ore to be gathered, lifted and positioned while separating the iron-ore within it using the electromagnet.

After installation and commissioning at surface level for trials, the crane will play a key role in a prototype ore-recovery process. Permanent installation underground will take place after six months of tests.

The mine’s surface-level prototype solution comprises five different types of machines working together. Ore spilled along the conveyor lines will first be recovered by small articulated loaders, which will place it on dump trucks for depositing in a purpose-built pit.

The jib crane will then retrieve the ore from the pit using a combined grabbing, magnetising, lifting, slewing and travel functionality, depositing the ore into a feed hopper, from where a secondary conveyor belt will transport it to rejoin the main ore stream on its way to the crushing plant.

“The Condra jib crane is the key to this solution, and has been designed and built to withstand a harsh underground working environment with minimal maintenance. It comprises a pillar- supported, double-girder beam, topped by the crab-mounted hoist – an arrangement that maximises the grab’s lifting height and optimises productivity in the execution of a repetitive, but complex lifting task within the spilled ore recovery process,” says Condra MD Marc Kleiner.

The crab has a range of equipment, holding not only the 5 t variable-speed-drive hoist but also the hydraulic power pack, two hydraulic hose reels serving the opening and closing functions of the orange-peel hydraulic grab, and the cable-reeling drum serving the electromagnet. Slewing action is delivered through the power from three swivel drives, and limited by rotary limit switches defining and limiting travel extremities.

The crane’s lift, swivel and crab movements, as well as all the hydraulic grab-and-release functions, can be operated by either remote control or a back-up pendant.

The large size of the machine and the complex task of designing it to achieve optimal productivity excluded most crane manufacturers from competing for the mine contract, Kleiner says.

“The jib crane market is very competitive at its entry level or small-machine end, and we do not actively compete in that segment. But as crane size and complexity increases, Condra becomes difficult to beat in terms of engineering and design expertise.

“We have worked hard over many years to achieve an ability to align with end-users and multiple third-party suppliers to deliver the required solution,” he adds.

Meanwhile, the principal co-suppliers for Condra’s ore recovery crane were specialised machinery and equipment company Rec-O-Quip, which designed the overall multiple-machine concept process, and scrap metal recycling equipment company MMH Recycling Systems, which supplied the five-tine, orange-peel hydraulic grab.

Increasing manufacturing efficiencies of the production process for this type of crane would make the company more competitive in bids for smaller, standardised designs. Further jib crane orders are anticipated, says Kleiner.

“These efficiencies will also reinforce Condra’s position as the manufacturer of choice for large jib cranes, such as the machine just completed,” he concludes.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation