Local supplier awarded conveyor distributorship

BULK BUY The range of bulk handling solutions manufactured by Convir is now being distributed locally by BLT WORLD

Bulk materials handling specialist BLT WORLD has announced that it was appointed a distributor of materials handling manufacturer Convir stockpiling equipment in Southern and Central Africa earlier this year.

The Convir range, which includes telescopic conveyors, stackers and other bulk handling equipment, has been designed for high efficiency in ports and terminals, mines and quarries, recycling, wood and paper, as well as agriculture and general industry.

“The BLT WORLD and Convir teams work closely with our customers to ensure the correct conveying equipment is installed for dependable operation and high productivity in every conveying application,” says BLT WORLD MD Ken Mouritzen.

“Our engineering services encompass strength, speed and power calculations, to provide technically advanced solutions for the most efficient equipment design and performance combination,” he adds.

He points out that an important advantage is that Convir belt, screw and scraper conveyor systems, used for transporting bulk products and sorted waste, are designed and manufactured to specific requirements to enable high productivity.

Additionally, all equipment complies with stringent quality and safety specifications.

The equipment includes a range of vertical, horizontal, open and closed conveyor systems for the automation of production and logistic lines.

All the Range

The Convir CV-TSP360 is a compact track-mounted mobile conveyor, with an integrated radial function, designed to maximise stockpile volumes from secondary equipment.

Its design flexibility allows the equipment to be used efficiently in various applications in both the long and short term.

Further, the Convir CV-TSP360’s applications include radial stockpiling from wash, processing, crushing or screening plants as well as radial stockpiling from mobile screens and various wet or air classification equipment.

“The Convir CV-TSP360 conveyor is also suitable for stockpiling construction and demolition waste, topsoil, coal and grain,” says Mouritzen.

Meanwhile, the Convir CV-TBC800 is a radial telescopic belt conveyor that efficiently reduces segregation, degradation, contamination and compaction.

This equipment offers 30% more stockpile capacity on the same footprint than conventional conveyors, when stockpiling in a trapezoidal shape.

It comes standard with long distance module belt conveyors which are designed to enhance operational efficiencies in quarries and mines where wheel loaders or trucks are normally required, thus reducing manpower, fuel consumption and the carbon footprint.

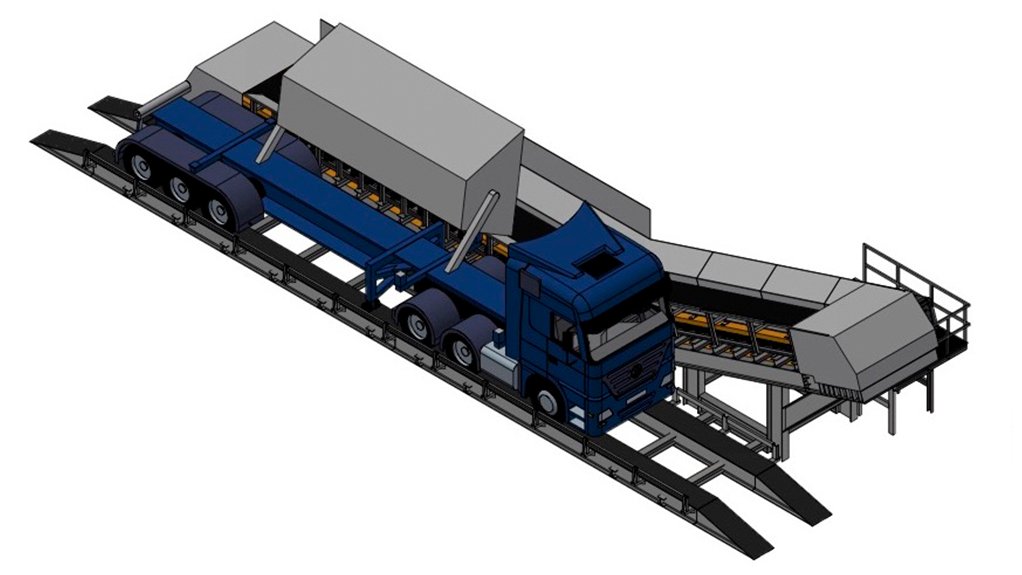

Moreover, Convir’s CV-RTU450 radial truck unloaders provide a continuous loading method directly from trucks into train wagons and barges, while Convir CV-RDC1200 radial stackers are suitable for efficiently moving various bulk materials including coal, aggregates, mulch, grain or scrap metal.

The radial stackers can be custom-built, with virtually any configuration of components or options required for a specific application.

Convir CV-TSC800/24 tracked stacker conveyor offers a compact, productive and mobile solution that can be continually fed by any crusher, screen or grinder.

“This system reduces fuel consumption, maintenance requirements and labour costs by up to 80%,” he enthuses.

Mouritzen comments that other bulk handling equipment available from BLT WORLD includes materials handling specialist SAMSON mobile material feeder equipment and ScrapeTec skirting for dust and spillage control of conveyor systems used in the handling of all bulk materials.

“The range also comprises MDS trommel screens and apron feeders for material processing and recycling,” he adds.

Meanwhile, BLT WORLD introduced ScrapeTec’s new SureSupport conveyor system to the African market, in August. The SureSupport conveyor system has been developed to improve material take-up and maximise the efficiency of skirting and sealing. This is achieved by correcting belt tracking, providing an effective seal at the transfer points, preventing material spillage and enhancing dust control. “The newly designed SureSupport system delivers support and stability to the belt at transfer points, which increases the effective ness of side sealing, enhances dust suppression and minimises material spillage.” Mouritzen adds that in conventional conveyors, the force of falling bulk materials causes a high belt load in the transfer area, resulting in belt degradation and increased material, energy and maintenance costs. To compensate for the belt load and to maintain efficient sealing within the transfer area, the idler density can be increased in the feed area. The SureSupport system efficiently reinforces the belt and prevents belt sag at the infeed, which is normally caused by the impact energy of falling materials being conveyed. Specially designed sliding rails prevent belt damage and tightness of the transfer is increased with the use of a combination skirting and sealing system that ensures even belt tracking. SureSupport operates in conjunction with ScrapeTec’s AirScrape side seal, offering a high-performance, dust-free and contactless skirting solution, with reduced material spillage.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation